Circuit board drilling and etching process

A circuit board and etching technology, applied in the directions of printed circuits, printed circuit manufacturing, electrical components, etc., can solve the problems of short circuit scrapping and film sandwiching between lines, and achieve the effect of avoiding electrostatic interference, improving quality and ensuring stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

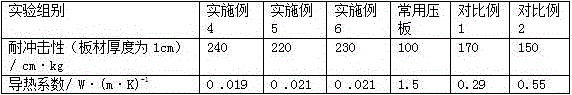

Embodiment 1

[0023] This embodiment provides a circuit board drilling and etching process, comprising the following steps:

[0024] S1. After cutting the circuit board substrate, pasting the dry film for making the inner circuit pattern, and browning the inner layer;

[0025] S2. Combine three circuit boards into a stack, and place a pressure plate on the top and bottom of a stack of circuit boards. After fixing, place on a drilling machine with a drilling backing plate and a positioning hole for drilling;

[0026] S3. Immersion copper electroplating on the whole board, and transfer the outer layer pattern to the laminated plate after copper immersion electroplating, and electroplate copper and tin on the pattern;

[0027] S4. Carry out the film removal treatment for the first time on the board after graphic electroplating, and re-attach the dry film, and use the cover hole film for the exposure and development treatment of the outer circuit;

[0028] S5. Alkaline etching treatment is car...

Embodiment 2

[0036] This embodiment provides a circuit board drilling and etching process, comprising the following steps:

[0037] S1. After cutting the circuit board substrate, pasting the dry film for making the inner circuit pattern, and browning the inner layer;

[0038] S2. Combine at least three circuit boards into a stack, and place a pressure plate on the top and bottom of a stack of circuit boards. After fixing, place it on a drilling machine with a drilling backing plate and positioning holes for drilling ;

[0039] S3. Immersion copper electroplating on the whole board, and transfer the outer layer pattern to the laminated plate after copper immersion electroplating, and electroplate copper and tin on the pattern;

[0040] S4. Carry out the film removal treatment for the first time on the board after graphic electroplating, and re-attach the dry film, and use the cover hole film for the exposure and development treatment of the outer circuit;

[0041] S5. Alkaline etching tre...

Embodiment 3

[0049] This embodiment provides a circuit board drilling and etching process, comprising the following steps:

[0050] S1. After cutting the circuit board substrate, pasting the dry film for making the inner circuit pattern, and browning the inner layer;

[0051] S2. Combine at least three circuit boards into a stack, and place a pressure plate on the top and bottom of a stack of circuit boards. After fixing, place it on a drilling machine with a drilling backing plate and positioning holes for drilling ;

[0052] S3. Immersion copper electroplating on the whole board, and transfer the outer layer pattern to the laminated plate after copper immersion electroplating, and electroplate copper and tin on the pattern;

[0053] S4. Carry out the film removal treatment for the first time on the board after graphic electroplating, and re-attach the dry film, and use the cover hole film for the exposure and development treatment of the outer circuit;

[0054] S5. Alkaline etching tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com