Fresh fruit yoghourt and preparation method thereof

A technology for yogurt and fresh fruit, applied to milk preparations, bacteria used in food preparation, dairy products, etc., can solve the problems of lack of fruit nutrition, poor taste, staleness, etc. good health effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

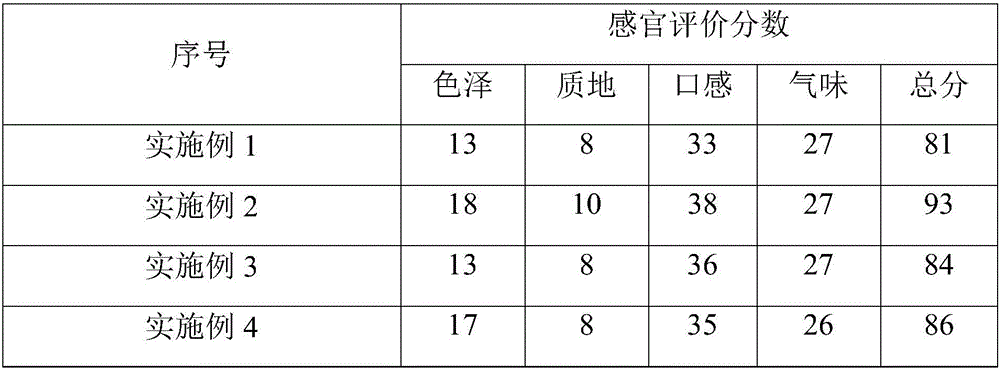

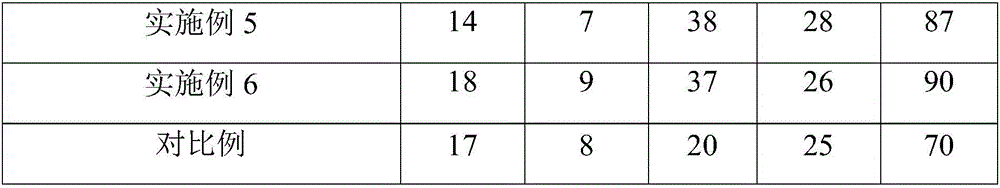

Examples

Embodiment 1

[0046] The preparation method of the fresh fruit yoghurt provided by the present embodiment comprises the following steps:

[0047] (1), 800kg of fresh milk at 5°C is heated to 48°C, and 80kg of sugar and 15kg of milk protein are added to make the protein content in the milk reach more than 3.9%. After stirring, it is hydrated for 30 minutes, and then homogenized at 17MPa;

[0048] (2) Sterilize the homogenized milk at 90°C for 250 seconds, then cool it down to 38°C, add 200g of probiotics to ferment, ferment for 4 hours until the pH is less than or equal to 4.58, and stop the fermentation to obtain yogurt, wherein , the probiotics are composed of Bifidobacterium lactis, Streptococcus thermophilus, Lactobacillus bulgaricus, Lactococcus lactis subsp. lactis and Lactococcus lactis subsp. cremoris;

[0049] (3), after pasteurizing 80kg of fresh fruit, add it in the yoghurt obtained in step (2) to obtain fresh fruit yoghurt.

Embodiment 2

[0051](1), 1000kg of fresh milk at 5°C is warmed up to 50°C, and 100kg of sugar and 18kg of milk protein are added to make the protein content in the milk reach more than 3.9%. After stirring, it is hydrated for 30 minutes, and then homogenized at 17MPa;

[0052] (2) Sterilize the homogenized milk at 90°C for 300 seconds, then cool it down to 40°C, add 250g of probiotics to ferment, ferment for 5 hours until the pH is less than or equal to 4.58, and stop the fermentation to obtain yogurt, wherein , the probiotics are composed of Bifidobacterium lactis, Streptococcus thermophilus, Lactobacillus bulgaricus, Lactococcus lactis subsp. lactis and Lactococcus lactis subsp. cremoris;

[0053] (3), after 100kg of fresh fruit is pasteurized, add in the yoghurt that step (2) obtains, obtains fresh fruit yoghurt.

Embodiment 3

[0055] (1), 1200kg of fresh milk at 8°C is warmed up to 53°C, and 120kg of sugar and 25kg of milk protein are added to make the protein content in the milk reach more than 3.9%. After stirring, it is hydrated for 40 minutes, and then homogenized at 19MPa;

[0056] (2) Sterilize the homogenized milk at 95°C for 350 seconds, then cool it down to 40°C, add 300g of probiotics to ferment, ferment for 6 hours until the pH is less than or equal to 4.58, and stop the fermentation to obtain yogurt, wherein , the probiotics are composed of Bifidobacterium lactis, Streptococcus thermophilus, Lactobacillus bulgaricus, Lactococcus lactis subsp. lactis and Lactococcus lactis subsp. cremoris;

[0057] (3), after pasteurizing 120kg of fresh fruit, add in the yoghurt that step (2) obtains, obtain the fresh fruit yoghurt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com