Mercury removal apparatus, a flue gas treatment system, and a method of removing mercury

A flue gas and equipment technology, applied in the field of mercury removal equipment, can solve the problems of reduced ultraviolet transmission, low efficiency of ultraviolet lamps, low mercury concentration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

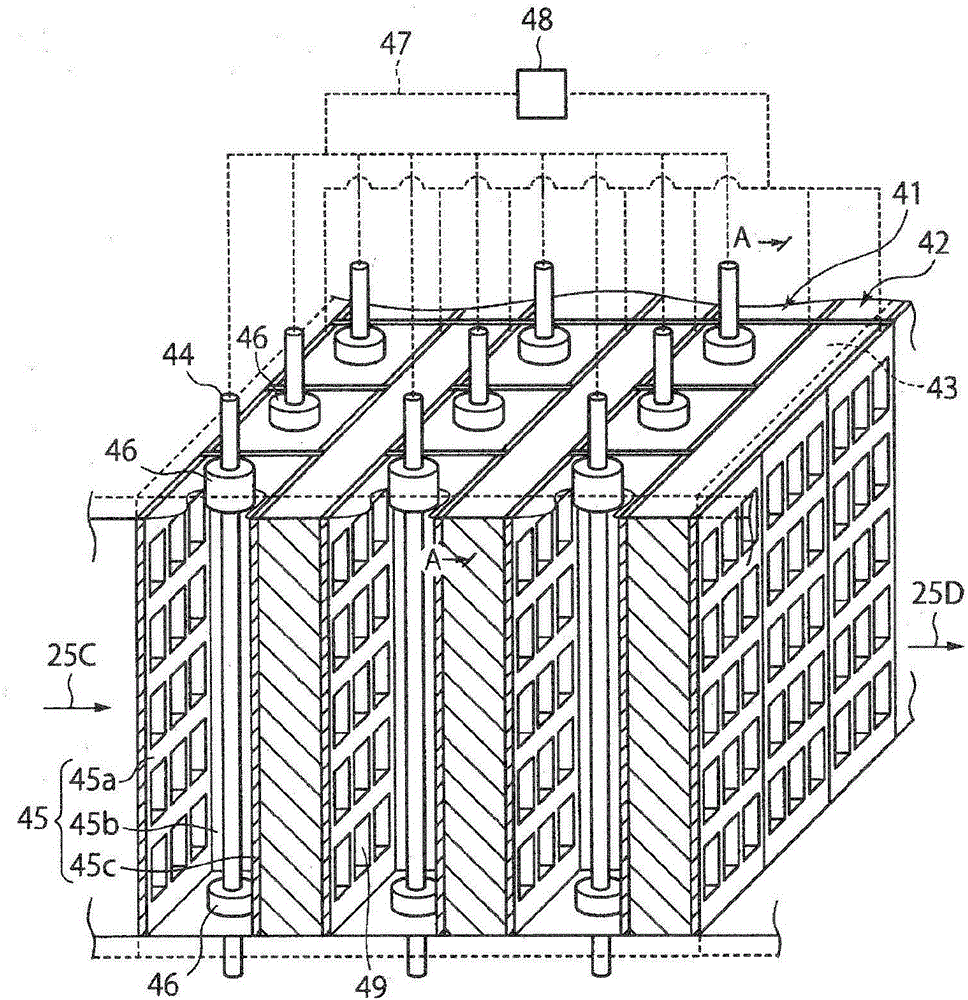

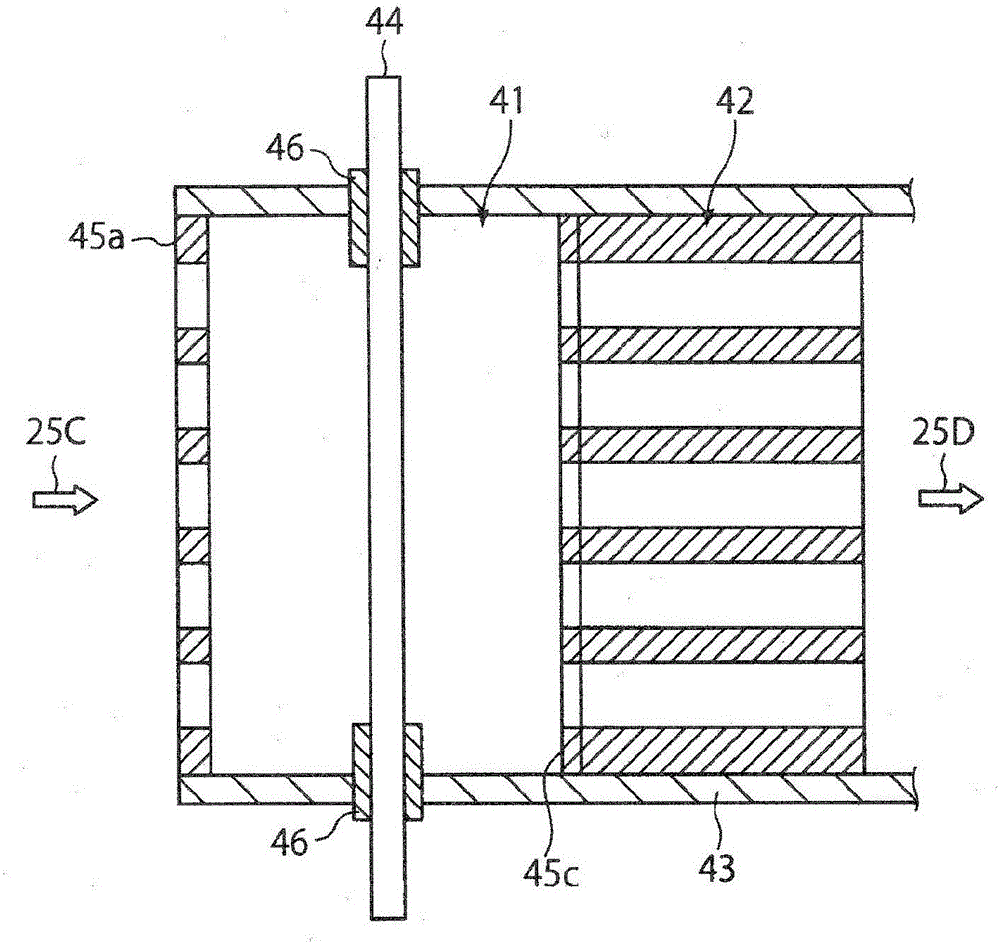

[0021] Reference will now be made in detail to the present embodiments, examples of which are illustrated in the accompanying drawings. Wherever possible, the same reference numbers will be used throughout the drawings to refer to the same or like elements.

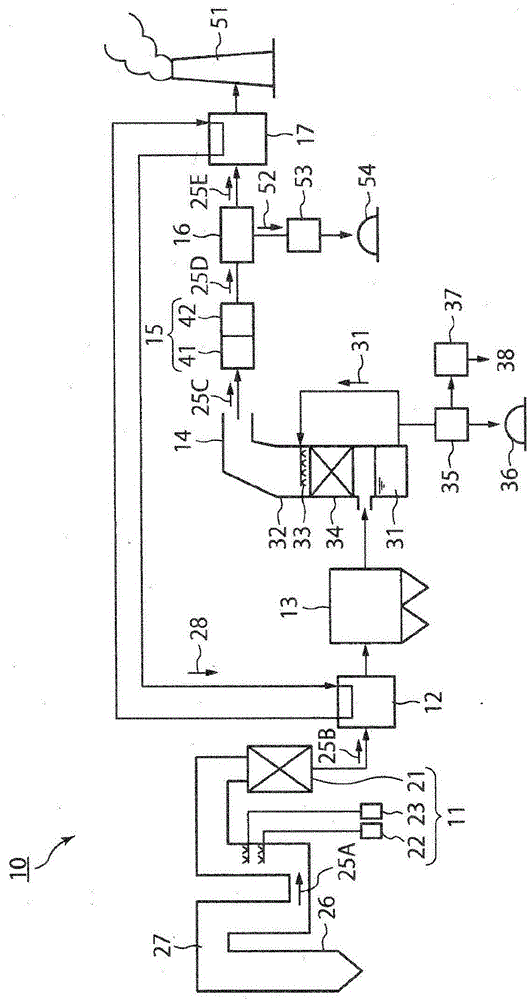

[0022] figure 1 is a view about a flue gas treatment system according to an embodiment. Such as figure 1 As shown in , the flue gas treatment system 10 includes a selective catalytic reduction device (SCR) 11, a heat exchanger (heat recovery side) 12, a dust collector 13, a flue gas desulfurization device (FGD) 14, a mercury oxidation device 15, a scrubber 16 and heat exchanger (reheat side) 17.

[0023] The gas discharged from the boiler 26 is flue gas 25A, the gas discharged from the SCR 11 is flue gas 25B, the gas discharged from the FGD 14 is flue gas 25C, the gas discharged from the mercury oxidation device 15 is flue gas 25D, and from the scrubber The gas discharged from 16 is flue gas 25E.

[0024] The SCR 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com