Iron-based metal-organic-framework material water oxidation catalyst and preparation method thereof

An organic framework, iron-based metal technology, applied in the preparation of cyanide reaction, preparation of organic compounds, organic compound/hydride/coordination complex catalysts, etc., can solve the problem of high cost of water oxidation catalysts and achieve good catalytic effect , good effect, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Preparation of Terephthalic Acid-Fe-Based Metal-Organic Framework Water Oxidation Catalyst

[0034] (1) Take terephthalic acid (166mg, 1.0mmol), dissolve it in 16-24mL N,N-dimethylformamide (DMF) (or only add 16mL), stir at room temperature for 5-20min Obtain a clear and transparent solution for subsequent use;

[0035] (2) Add 270~1350mg FeCl to the clear and transparent solution obtained in step (1) 3 ·6H 2 0, stirred at room temperature for 5-20 min to obtain a mixed solution for subsequent use;

[0036] (3) Transfer the mixed solution obtained in step (2) to the reaction kettle, react at 100-150°C for 48-72 hours, filter after cooling, wash with ethanol, and obtain the solid product Fe III (OH)[O 2 C-C 6 h 4 -CO 2 ] is the iron-based metal-organic framework water oxidation catalyst.

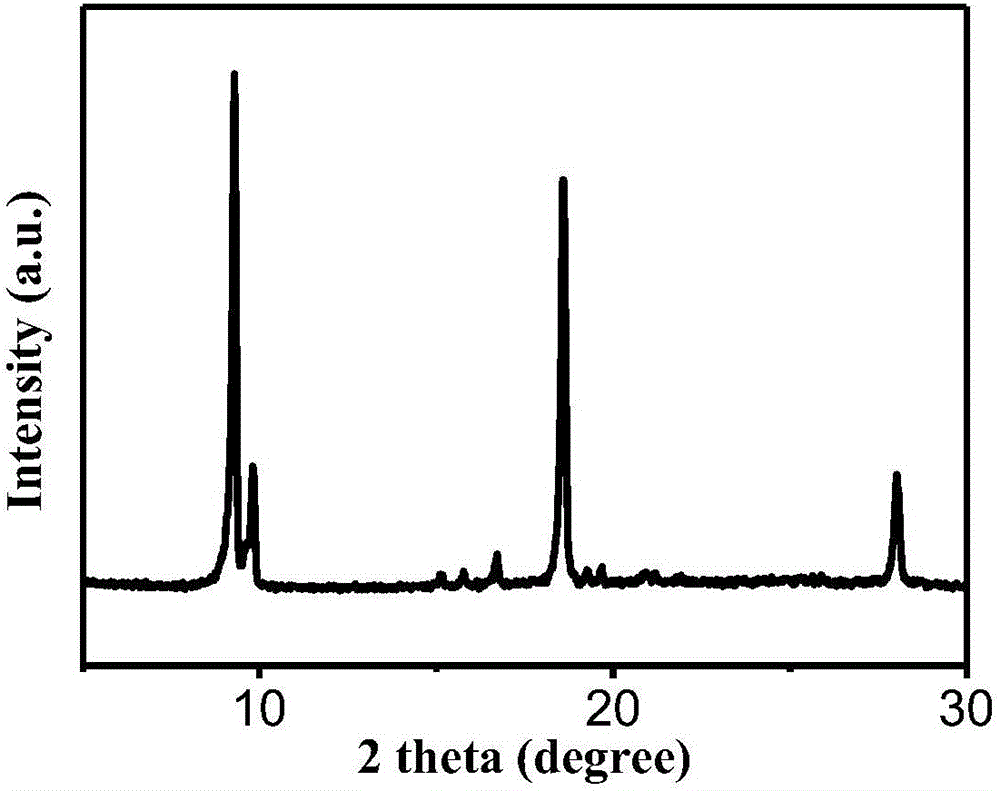

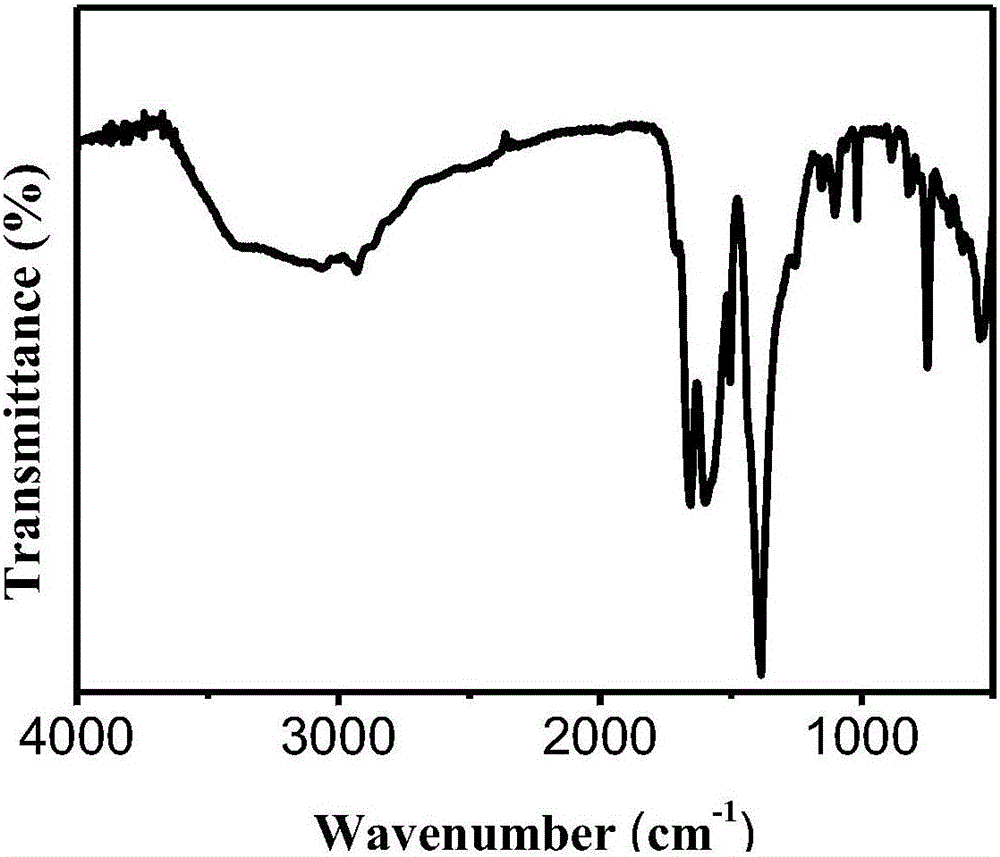

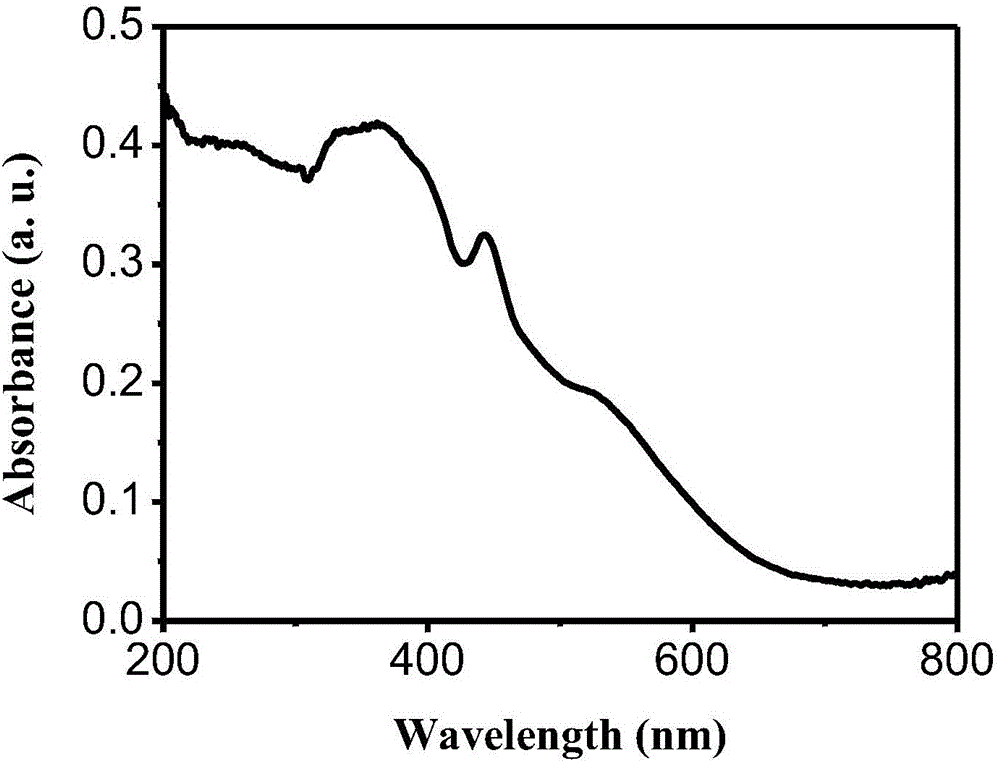

[0037] The obtained iron-based metal-organic framework material is characterized by XRD, which proves that the framework structure of the material is MIL-53 (see attached figu...

Embodiment 2

[0046] Preparation of 2-aminoterephthalic acid-iron-based metal-organic framework as catalyst for water oxidation

[0047] (1) Take 2-aminoterephthalic acid (181mg, 1.0mmol), and dissolve it in 16-24mL N,N-dimethylformamide (DMF) (or just add 24mL), stir at room temperature 5 ~ 20min to get a clear and transparent solution, set aside;

[0048] (2) Add 270~1350mg FeCl to the clear and transparent solution obtained in step (1) 3 ·6H 2 0, stirred at room temperature for 5-20 min to obtain a mixed solution for subsequent use;

[0049] (3) Transfer the mixed solution obtained in step (2) to the reaction kettle, react at 100-150°C for 48-72 hours, filter after cooling, wash with ethanol, and obtain the solid product Fe III (OH)[O 2 C-C 6 h 4 -CO 2 ]NH 2 That is, the iron-based metal-organic framework material water oxidation catalyst.

Embodiment 3

[0051] Preparation of 2-Hydroxyterephthalic Acid-Fe-Based Metal-Organic Framework Water Oxidation Catalyst

[0052] (1) Take 2-hydroxyterephthalic acid (182mg, 1.0mmol), dissolve it in 16-24mL N,N-dimethylformamide (DMF), stir at room temperature for 5-20min to obtain clear and transparent solution, spare;

[0053] (2) Add 270~1350mg FeCl to the clear and transparent solution obtained in step (1) 3 ·6H 2 0, stirred at room temperature for 5-20min to obtain a mixed solution for subsequent use;

[0054] (3) Transfer the mixed solution obtained in step (2) to the reaction kettle, react at 100-150°C for 48-72 hours, filter after cooling, wash with ethanol, and obtain the solid product Fe III (OH)[O 2 C-C 6 h 4 -CO 2 ]OH is the iron-based metal-organic framework water oxidation catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com