Wet grinding machine for industrial treatment of concrete admixture

A technology of admixture and wet mill, applied in grain processing and other directions, can solve the problems of not reaching industrialized production, long feeding time, long time, etc., to reduce waste of resources, large processing capacity, and improve economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

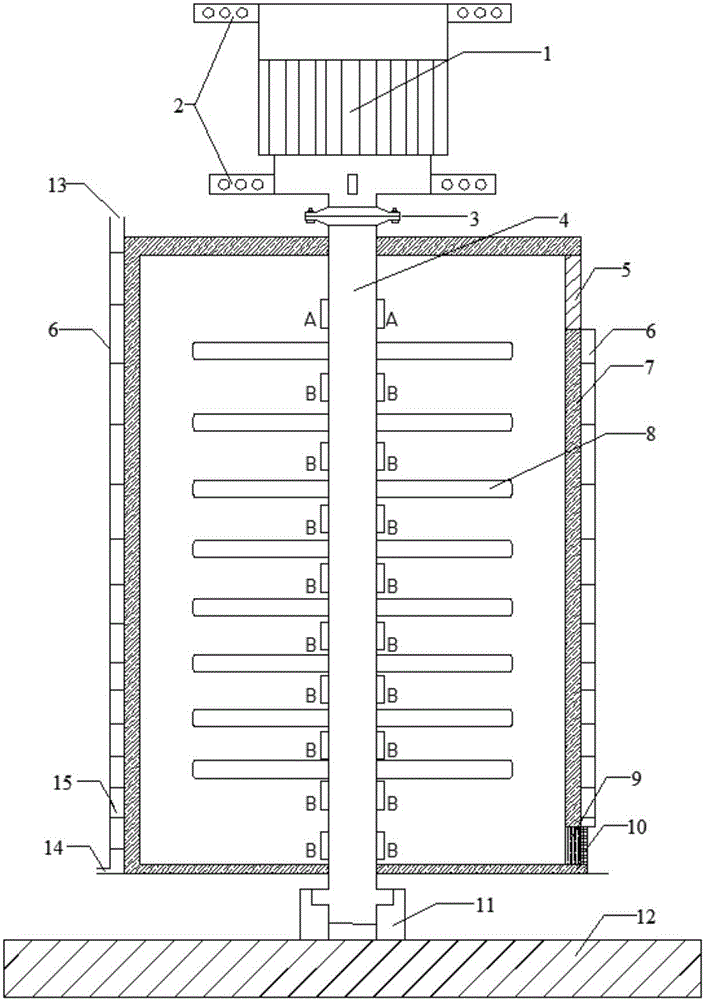

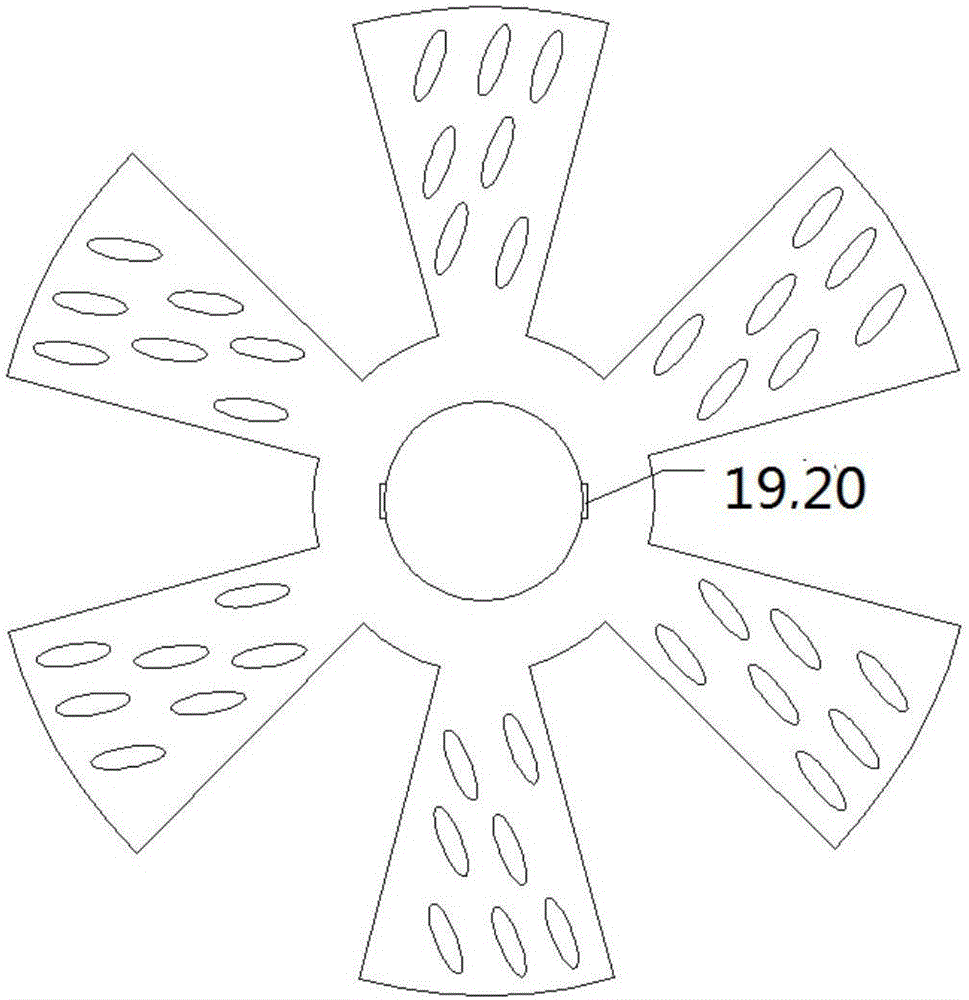

[0012] The present invention will be described in detail below with reference to the accompanying drawings.

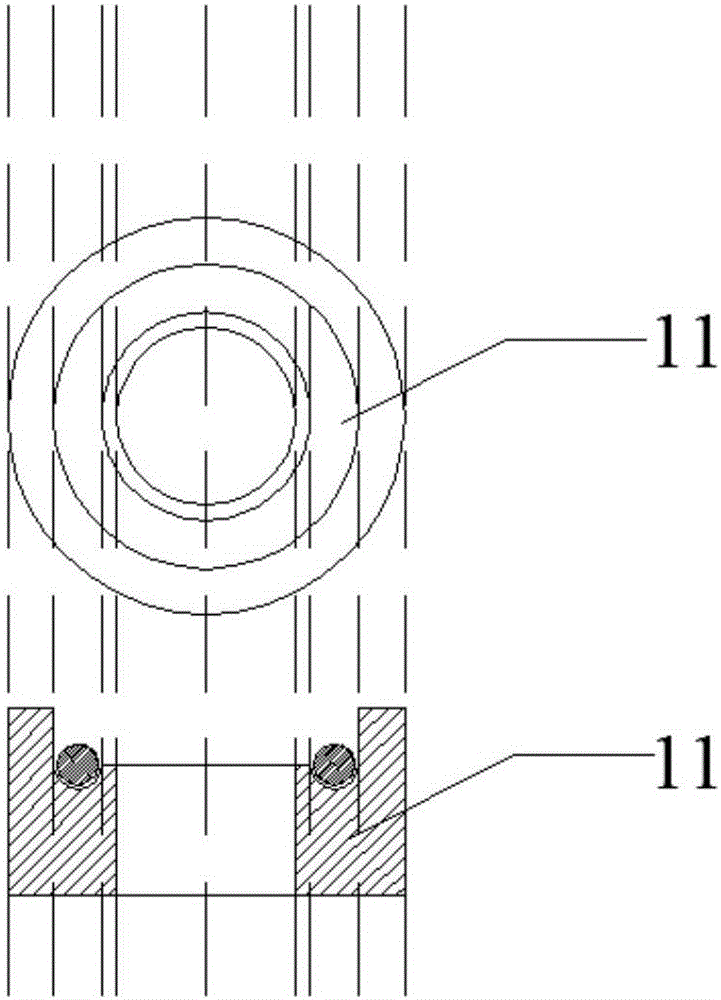

[0013] refer to figure 1 , 5 , in order to prevent polarization and ensure the stability of the body, the cylinder 7 is connected to the embedded component 17 through the connecting member 18, and the embedded component 17 is fixed on the reinforced concrete column 16. The upper part of the rotating shaft 4 is connected with the power equipment 1 through the coupling 3 , and the lower part is carried by the bearing member 11 . The bearing member 11 is firmly connected with the basic concrete structure 12, that is, it is carried on the basic concrete structure. The rotating shaft 4 runs through the cylindrical body, and the penetrating part is sealed by a sealing ring. The power equipment 1 is fixed on the bracket 16 through the connecting member 2 .

[0014] The cylinder is 3-5.5m high and 1.5-2.5m in diameter. Due to the large cylinder, the bracket 16 adopts the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com