Inorganic synthesis method for regulating morphology of ZSM-5 molecular sieve

An inorganic synthesis, ZSM-5 technology, applied in the direction of crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., can solve the problems of irreversible agglomeration of nano ZSM-5 molecular sieve, increased cost, environmental pollution, etc. , to achieve good economic and social benefits, reduce pollution, and avoid waste gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

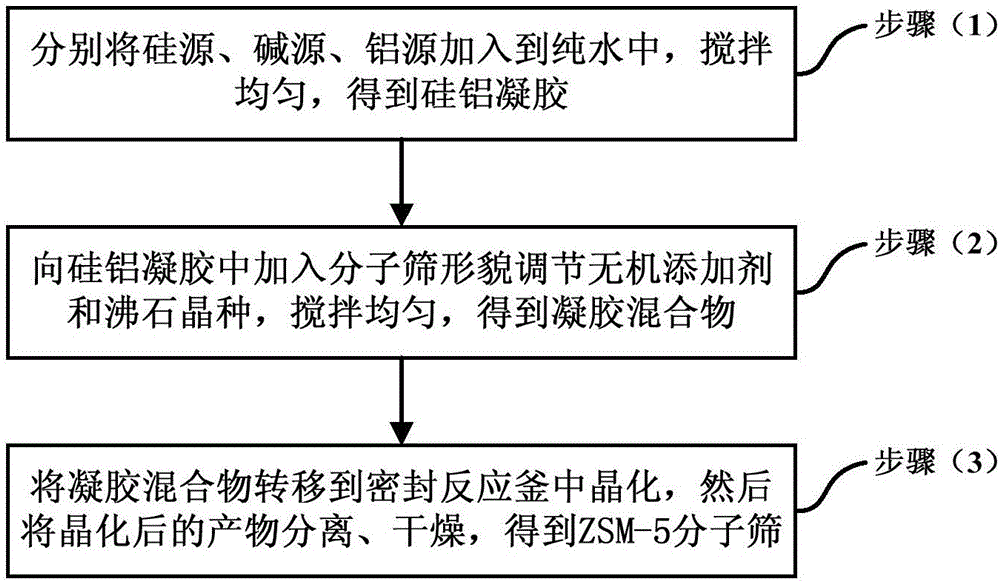

[0032] like figure 1 As shown, the present invention relates to a kind of inorganic synthesis method of regulating and controlling ZSM-5 molecular sieve morphology, and it at least comprises the following steps:

[0033] Step (1): Add silicon source, alkali source, and aluminum source into pure water respectively, and stir evenly to obtain silica-alumina gel.

[0034] Step (2): adding molecular sieve shape-adjusting inorganic additives and zeolite seed crystals to the silica-alumina gel, and stirring evenly to obtain a gel mixture.

[0035] Step (3): transfer the gel mixture to a sealed reaction kettle for crystallization, and then separate and dry the crystallized product to obtain ZSM-5 molecular sieve.

[0036] Among them, the morphology of the ZSM-5 molecular sieve is suitable for regulation by adjusting the morphology of the molecular sieve and adjusting the addition amount of inorganic additives.

[0037]In step (2), the molecular sieve morphology adjustment inorganic ...

Embodiment 1

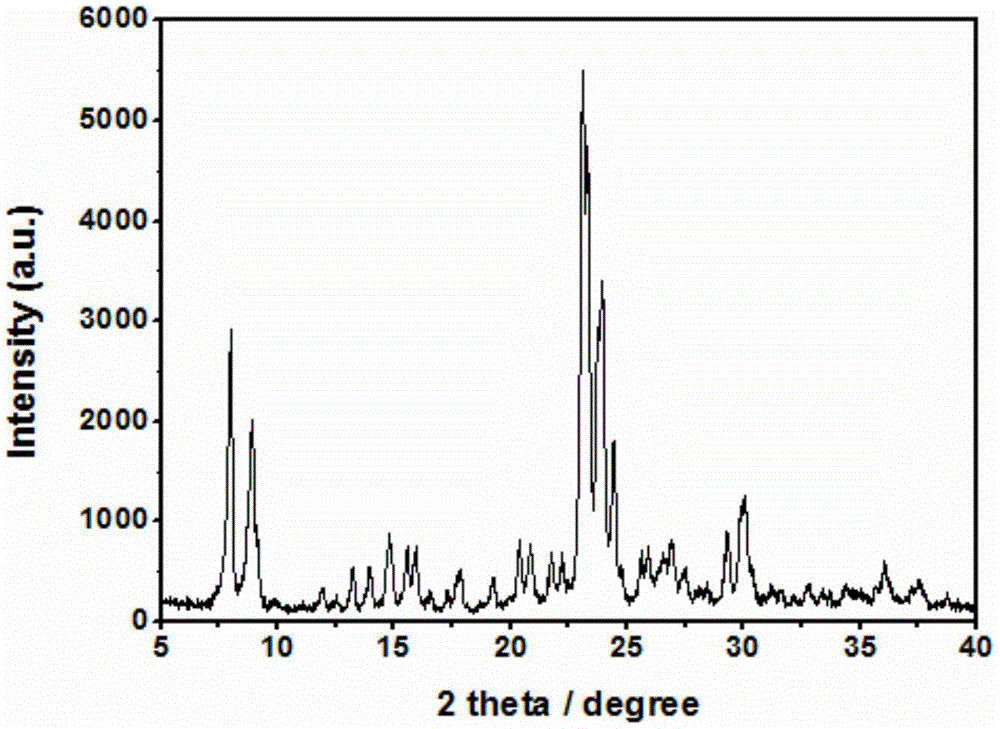

[0049] Take by weighing 113g silica sol (SiO 2 Content is 30%) and 77g pure water are mixed, then add 1.51g sodium hydroxide, after stirring evenly, then add 3.1g sodium aluminate (Al 2 o 3 content is 75%), continue to stir until a uniform silica-alumina gel is formed, and the molar ratio of each component in the silica-alumina gel is SiO 2 :Al 2 o 3 : Na 2 O: H 2 O=30:1:2:460. After that, add SiO 2 :Al 2 o 3 =25 MFI type molecular sieve seed crystal 1.7g stirred evenly, finally added 2.6g hydrogen peroxide solution (H 2 o 2 content is 30%), after stirring evenly, the mixture was transferred to a stainless steel sealed reaction kettle with polytetrafluoroethylene lining, placed in an oven at 170°C, and crystallized for 48 hours. The crystallized product was cooled, separated (including filtering and washing) and then dried at 120°C for 8 hours to obtain ZSM-5 molecular sieve.

[0050] figure 2 It is the XRD spectrogram of the ZSM-5 molecular sieve sample obtained...

Embodiment 2

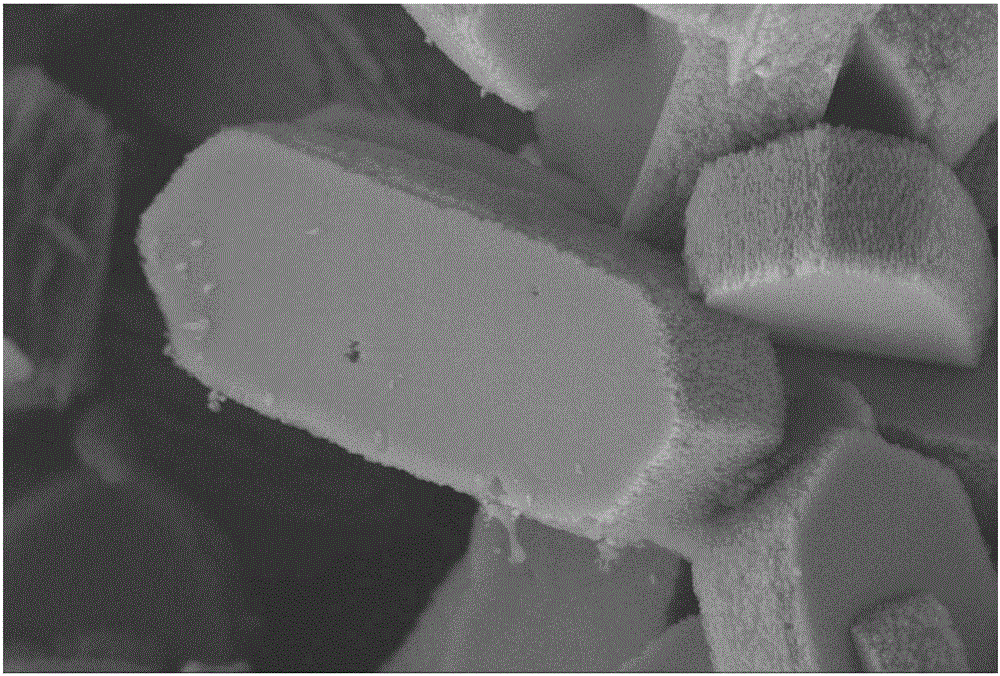

[0053] Take by weighing 184g silica sol (SiO 2 content is 30%) and 101g water are mixed, then add 10.3g sodium hydroxide, after stirring evenly, then add 2.5g pseudo-boehmite (Al 2 o 3 Content is 75%) and 1.2g zinc nitrate, continue to stir until forming uniform silica-alumina gel, the molar ratio of each composition in this silica-alumina gel is SiO 2 :Al 2 o 3 : Na 2 O: H 2 O=50:1:7:700. After that, add SiO 2 :Al 2 o 3 =400 MFI type molecular sieve seed crystal 4.5g stir evenly, finally add 1.5g hydrogen peroxide solution (H 2 o 2 content 30%), after stirring evenly, the mixture was transferred to a stainless steel sealed reaction kettle with polytetrafluoroethylene lining, placed in an oven at 155° C., and crystallized for 60 hours. The crystallized product was cooled, separated (including filtering and washing), and then dried at 120°C for 8 hours to obtain Zn-ZSM-5 molecular sieve.

[0054] Figure 4 It is the scanning electron microscope picture of the ZSM-5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com