A kind of inorganic synthesis method for regulating the morphology of zsm-5 molecular sieves

A ZSM-5, inorganic synthesis technology, applied in the direction of crystalline aluminosilicate zeolite, borocarbonane silicone crystalline aluminosilicate zeolite, etc., can solve the problems of irreversible agglomeration of nano ZSM-5 molecular sieves, environmental pollution, increased cost, etc. , to achieve good economic and social benefits, reduce pollution, and avoid the effects of exhaust gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

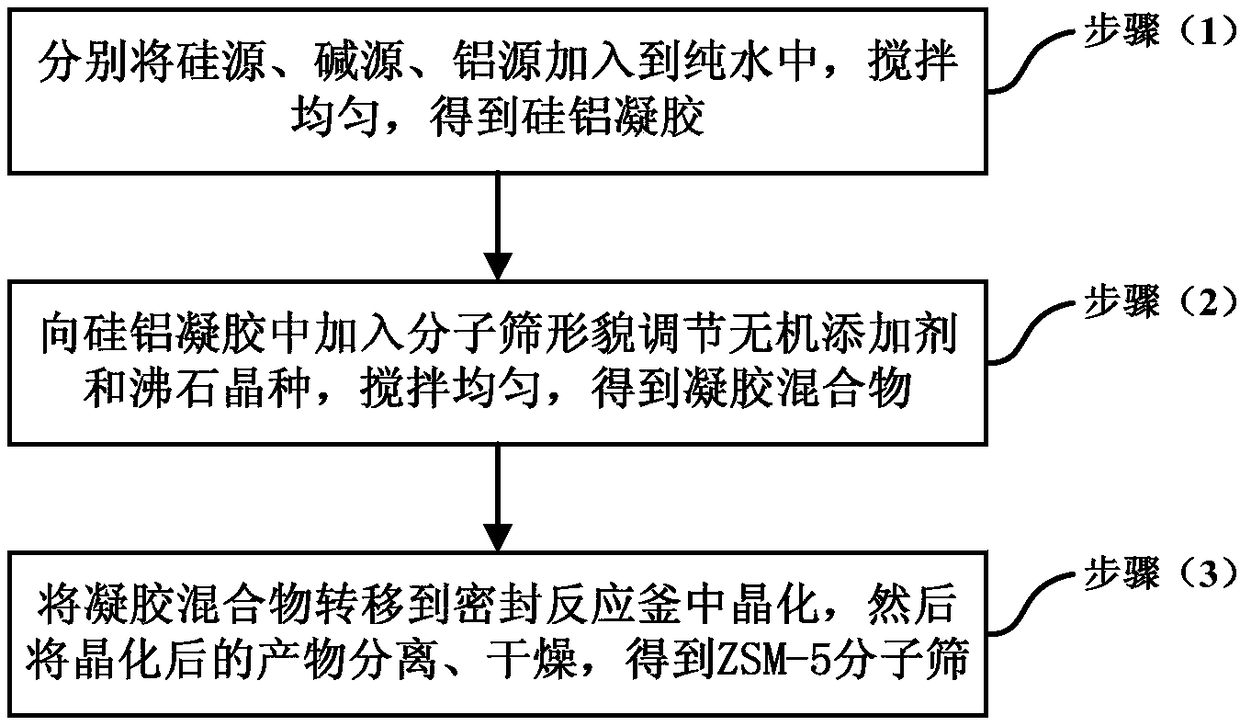

[0032] Such as figure 1 所示,本发明涉及一种调控ZSM-5分子筛形貌的无机合成方法,其至少包括如下步骤:

[0033] 步骤(1):分别将硅源、碱源、铝源加入到纯水中,搅拌均匀,得到硅铝凝胶。

[0034] 步骤(2):向硅铝凝胶中加入分子筛形貌调节无机添加剂和沸石晶种,搅拌均匀,得到凝胶混合物。

[0035] 步骤(3):将凝胶混合物转移到密封反应釜中晶化,然后将晶化后的产物分离、干燥,得到ZSM-5分子筛。

[0036] 其中,ZSM-5分子筛的形貌适于通过调节分子筛形貌调节无机添加剂的添加量来进行调控。

[0037]In step (2), the molecular sieve morphology adjustment inorganic additive is hydrogen peroxide solution. And, the addition amount of hydrogen peroxide solution is 0.15%~5% of the mass of silica-alumina gel, as a more preferred scheme, hydrogen peroxide solution 2 o 2 The amount added is 0.3% to 1.5% of the mass of the silica-alumina gel. In addition, H in hydrogen peroxide solution 2 o 2 The content is 2% ~ 40%, preferably, hydrogen peroxide solution H 2 o 2 The content is 30%. It is worth mentioning that H 2 o 2 It is an environmentally friendly inorganic reagent. It can not only be added to the synthesis gel of molecular sieves to regulate molecular sieve crystals, but also can be ...

Embodiment 1

[0049] Take by weighing 113g silica sol (SiO 2 Content is 30%) and 77g pure water are mixed, then add 1.51g sodium hydroxide, after stirring evenly, then add 3.1g sodium aluminate (Al 2 o 3 content is 75%), continue to stir until a uniform silica-alumina gel is formed, and the molar ratio of each component in the silica-alumina gel is SiO 2 :Al 2 o 3 : Na 2 O: H 2 O=30:1:2:460. After that, add SiO 2 :Al 2 o 3 =25 MFI type molecular sieve seed crystal 1.7g stirred evenly, finally added 2.6g hydrogen peroxide solution (H 2 o 2 content is 30%), after stirring evenly, the mixture was transferred to a stainless steel sealed reaction kettle with polytetrafluoroethylene lining, placed in an oven at 170°C, and crystallized for 48 hours. The crystallized product was cooled, separated (including filtering and washing) and then dried at 120°C for 8 hours to obtain ZSM-5 molecular sieve.

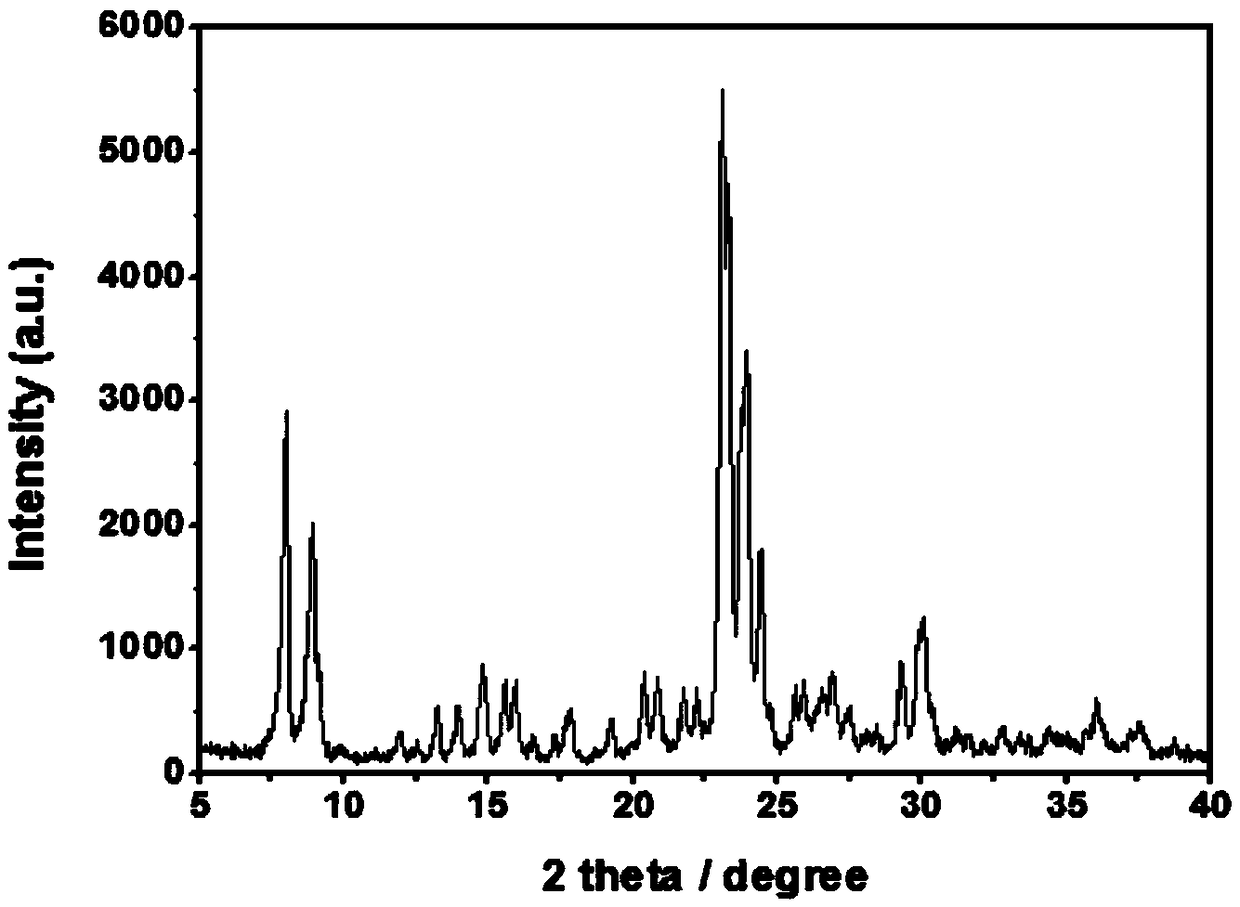

[0050] figure 2 It is the XRD spectrogram of the ZSM-5 molecular sieve sample obtained...

Embodiment 2

[0053] Take by weighing 184g silica sol (SiO 2 content is 30%) and 101g water are mixed, then add 10.3g sodium hydroxide, after stirring evenly, then add 2.5g pseudo-boehmite (Al 2 o 3 Content is 75%) and 1.2g zinc nitrate, continue to stir until forming uniform silica-alumina gel, the molar ratio of each composition in this silica-alumina gel is SiO 2 :Al 2 o 3 : Na 2 O: H 2 O=50:1:7:700. After that, add SiO 2 :Al 2 o 3 =400 MFI type molecular sieve seed crystal 4.5g stir evenly, finally add 1.5g hydrogen peroxide solution (H 2 o 2 content 30%), after stirring evenly, the mixture was transferred to a stainless steel sealed reaction kettle with polytetrafluoroethylene lining, placed in an oven at 155° C., and crystallized for 60 hours. The crystallized product was cooled, separated (including filtering and washing), and then dried at 120°C for 8 hours to obtain Zn-ZSM-5 molecular sieve.

[0054] Figure 4 It is the scanning electron microscope picture of the ZSM-5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com