Method for reaction of sucralose esterified single solvent

A sucralose, esterification reaction kettle technology, applied in chemical instruments and methods, esterification saccharides, sugar derivatives and other directions, can solve the problems of high solvent recovery and energy consumption, shortened production cycle, complex process, etc., to save energy The effect of cost consumption, shortening production cycle, and reducing consumption of raw materials and energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

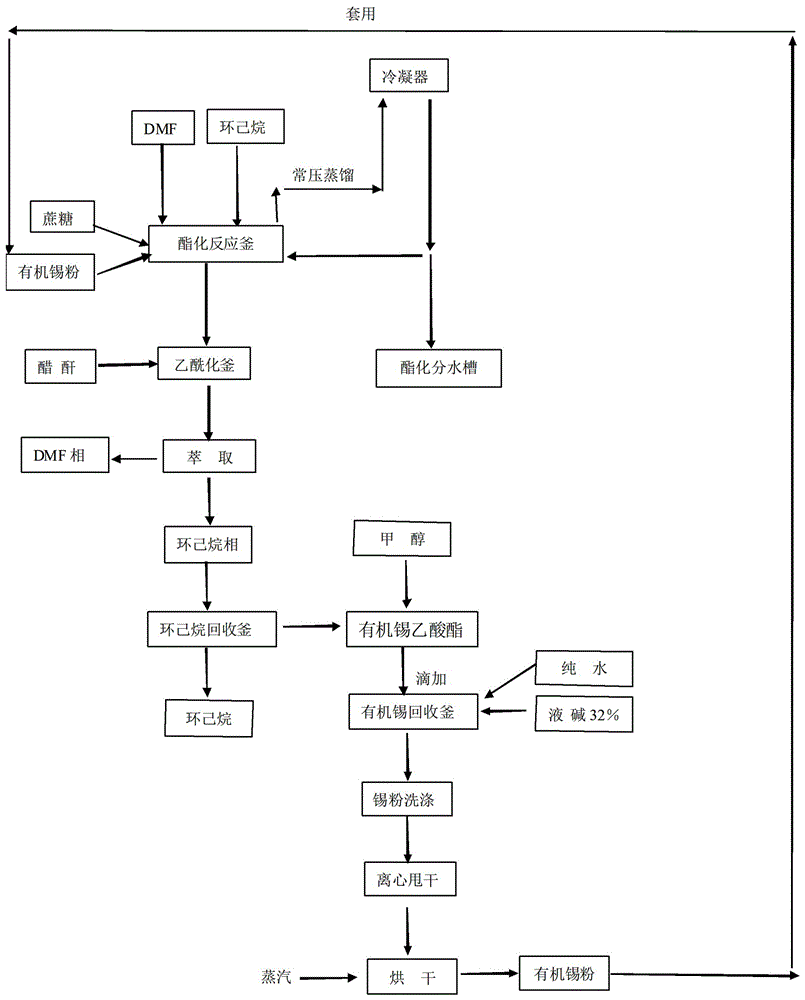

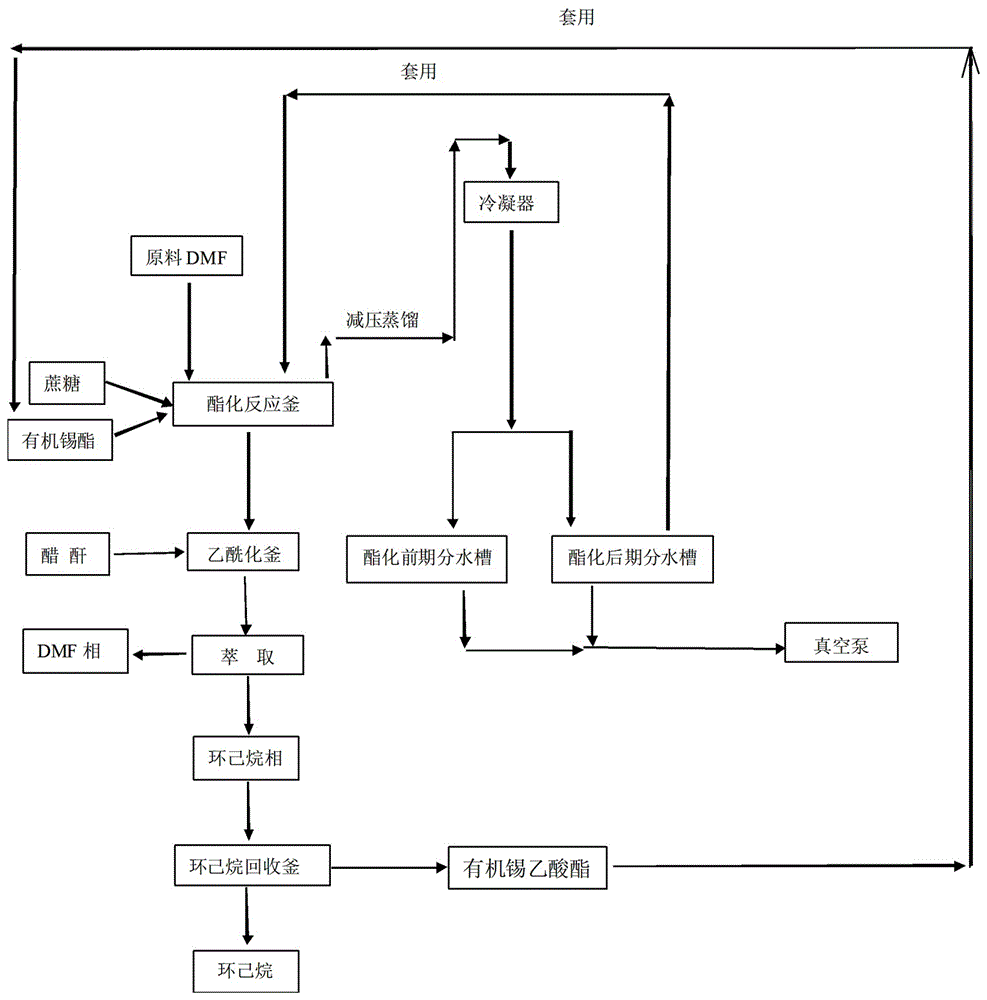

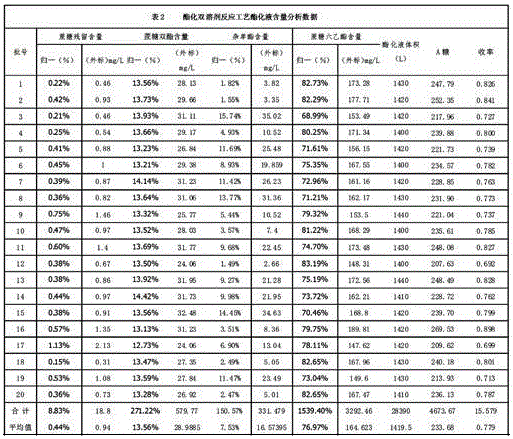

[0014] Such as figure 2 As shown, accurately put 700L of DMF and 1200L of DMF recovered from the previous batch into the esterification kettle, and put 300kg of sucrose into the esterification kettle, heat up, control the steam pressure at 1.8-2.0mpa, and turn off when the temperature rises to 70℃ Steam valve, let it naturally heat up to 84 ~ 86 ℃ and stir for 1.5 hours to fully dissolve the sugar.

[0015] Turn on the vacuum pump and control the vacuum negative pressure at -0.085~-0.09mpa, pour 600kg of organotin acetate into the esterification kettle, and turn on the steam to raise the pressure at 0.04~0.05MPa to control the temperature of the kettle At 68~70℃, under the condition of negative pressure -0.098mpa~-0.01mpa, the temperature of the kettle is normally at 76~78℃, continue to bring the negative pressure to cool down until the temperature of the kettle drops to 68~70℃ (observe the distillation situation during the test) ), open the steam valve, and control the stea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com