Red green and blue three-basic-color fluorescent composite material and preparation method and application thereof

A composite material, three-primary color technology, applied in luminescent materials, chemical instruments and methods, sustainable buildings, etc., can solve problems such as luminous efficiency attenuation, and achieve stable state, good luminous efficiency, and easy application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

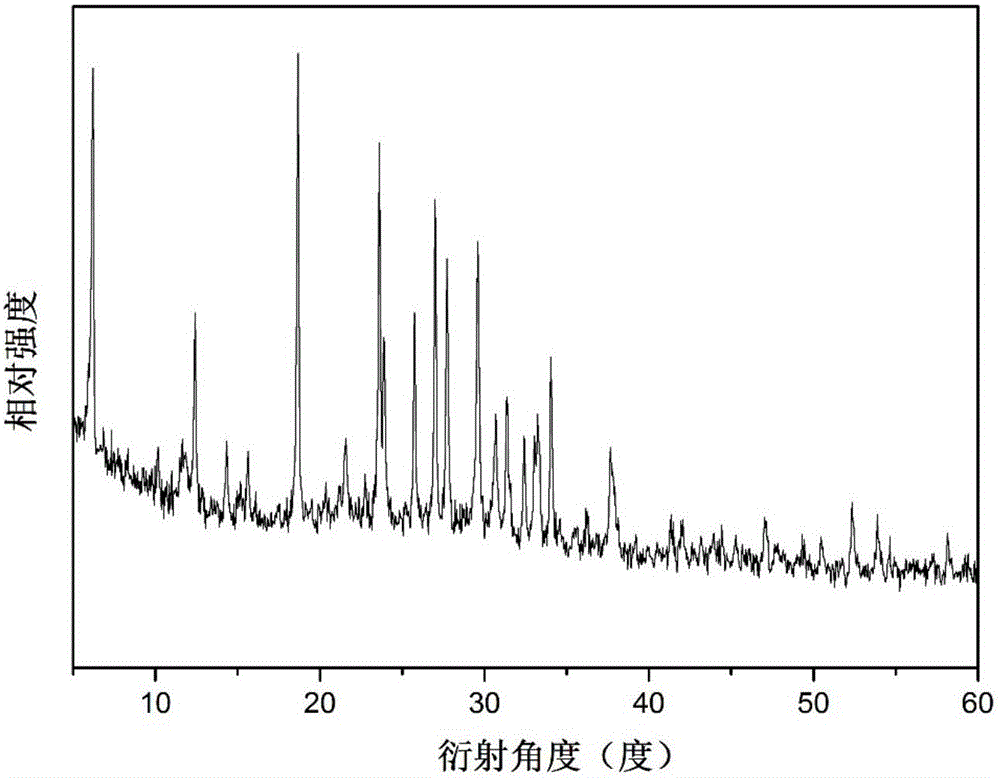

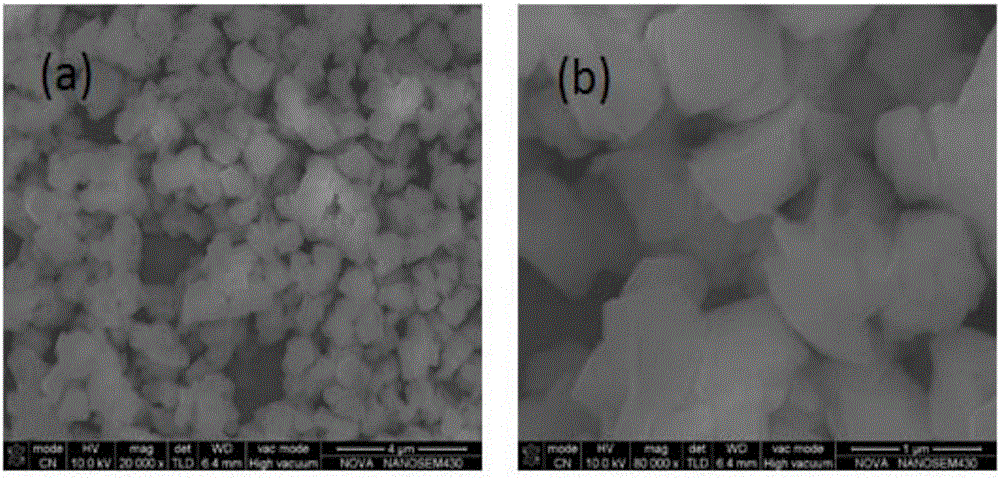

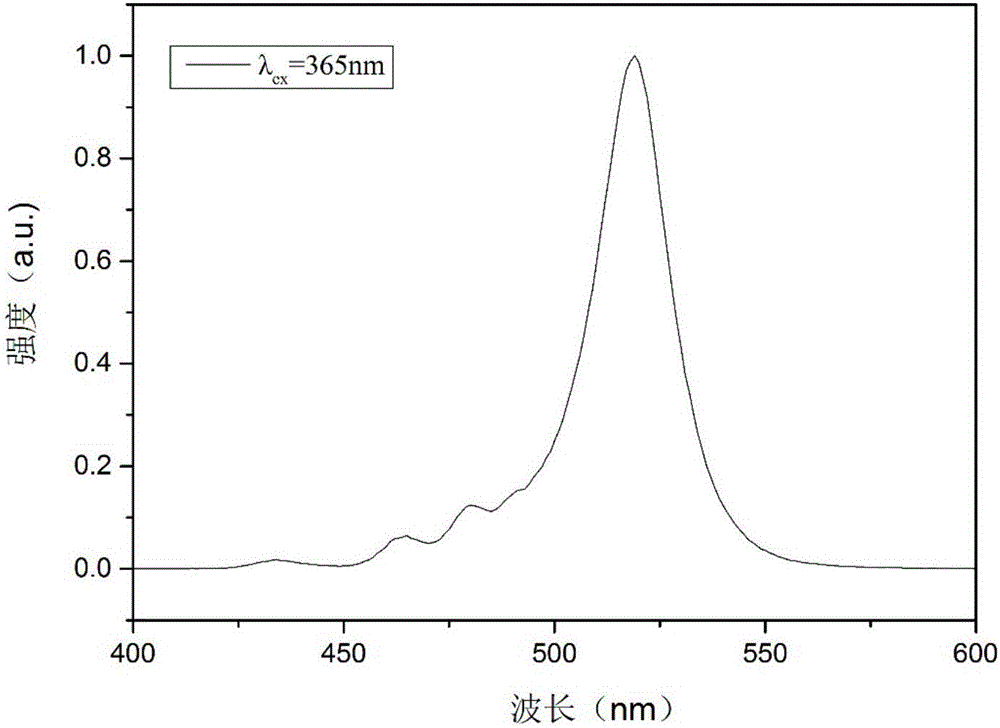

[0042] A preparation method of red, green and blue fluorescent composite material (green fluorescent composite material), which specifically includes the following steps:

[0043] (1) Weigh accurately 1.064g cesium bromide (CsBr) (0.005mol), add 5ml distilled water and stir to dissolve cesium bromide at room temperature to obtain cesium bromide solution; add 1.5g Y-type molecular sieve to the cesium bromide solution and stir at room temperature 36h (the stirring speed is 400r / min), centrifuge (the centrifugal speed is 3500r / min) for 5min, take the lower sample, wash twice with distilled water, and dry it at 80℃ for 30min, then calcinate at 300℃ for 30min, (calcined The system is to increase the temperature from room temperature to 300°C at a rate of 5°C / min, and keep the temperature at 300°C for 30 minutes), and then cool to room temperature with the furnace to obtain a Cs ion-exchanged Y-type molecular sieve;

[0044] (2) Combine octadecene (ODE) 5ml, oleic acid (OA) 1ml, oleylami...

Embodiment 2

[0050] A preparation method of red, green and blue fluorescent composite material (green fluorescent composite material), which specifically includes the following steps:

[0051] (1) Weigh accurately 1.064g cesium bromide (CsBr), add 5ml of distilled water and stir to dissolve cesium bromide at room temperature to obtain a cesium bromide solution; add 1.5g Y-type molecular sieve to the cesium bromide solution, and stir at room temperature for 36h (stirring speed 450r / min), centrifugation (speed of centrifugation is 3500r / min) for 5min, take the lower sample, wash twice with distilled water, and dry at 80℃ for 30min, then calcinate at 300℃ for 30min (calcination system is 5℃ / min The rate is increased from room temperature to 300°C, and the temperature is kept at 300°C for 30 minutes), and then cooled to room temperature with the furnace to obtain a Cs ion exchanged Y-type molecular sieve;

[0052] (2) Combine octadecene (ODE) 6.5ml, oleic acid (OA) 1.5ml, oleylamine (OAm) 1.5ml, le...

Embodiment 3

[0056] A preparation method of red, green and blue fluorescent composite material (green fluorescent composite material), which specifically includes the following steps:

[0057] (1) Weigh accurately 1.064g cesium bromide (CsBr), add 5ml of distilled water and stir to dissolve cesium bromide at room temperature to obtain a cesium bromide solution; add 1.5g Y-type molecular sieve to the cesium bromide solution, and stir at room temperature for 24h (stirring speed 400r / min), centrifugation (speed of centrifugation is 3500r / min) for 5min, take the lower sample, wash twice with distilled water, and dry at 80℃ for 30min, then calcinate at 300℃ for 30min (calcination system is 5℃ / min The rate is increased from room temperature to 300°C, and the temperature is kept at 300°C for 30 minutes), and then cooled to room temperature with the furnace to obtain a Cs ion exchanged Y-type molecular sieve;

[0058] (2) Combine octadecene (ODE) 10ml, oleic acid (OA) 2ml, oleylamine (OAm) 2ml, lead br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com