Special synthesized cutting fluid with ultra-high lubricating property for black metal and preparation method of special synthesized cutting fluid

A lubricating performance, ferrous metal technology, applied in the field of cutting fluid for metal processing, can solve the problems of narrow processing technology adaptability, insufficient lubrication performance of synthetic cutting fluid, etc., achieve processing environment adaptability, strong antibacterial ability, and excellent antirust performance , long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

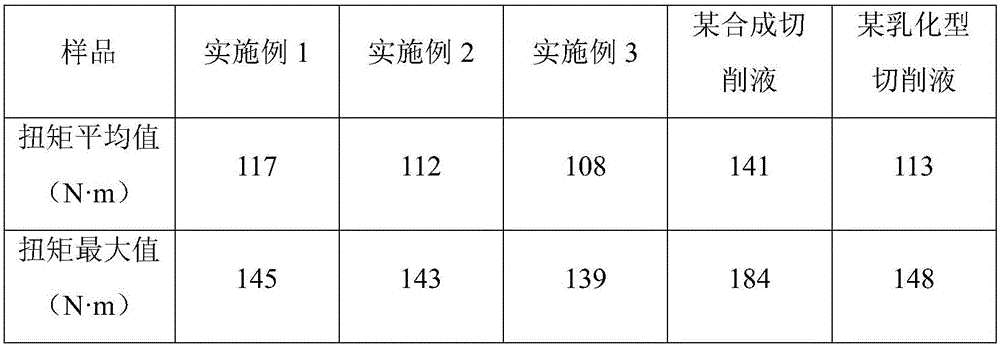

[0023] While stirring, add 5% monoethanolamine, 12% triethanolamine, 1% vulcanized modified rapeseed oil, and 2% neodecanoic acid, heat to 50-60°C, keep stirring for 30 minutes, then turn off the heating; gradually add tap water 59.6%, Tetrasodium EDTA 1%, organic tribasic acid 3%, borate 5%, polyoxyethylene polyoxypropylene ether 5%, glycerin 4%, benzotriazole 0.2%, morpholine derivatives 2%, stirring Until the solution is transparent; add 0.2% emulsified silicone oil, and stir for 20 minutes to obtain the finished product.

[0024] The special synthetic cutting fluid for ferrous metals with ultra-high lubricating properties prepared in this example has excellent rust resistance, cleaning and sedimentation properties, and is suitable for cutting and grinding of ordinary ferrous metals, especially for roughing of bearing rings. , Fine grinding. The diluent concentration of 2-4% is suitable for general grinding, and the diluent concentration of 3-6% is suitable for turning and...

Embodiment 2

[0026] While stirring, add 5% monoethanolamine, 15% triethanolamine, 2% phosphoric acid ester, 3% chlorinated fatty acid, 4% neodecanoic acid, heat to 50-60°C, keep stirring for 30 minutes, then turn off the heating; gradually add tap water 49.4 %, tetrasodium EDTA 1%, organic tribasic acid 3%, boric acid ester 5%, self-emulsifying ester 5%, glycerin 5%, benzotriazole 0.2%, morpholine derivatives 2%, iodopropyl Add 0.2% butyl alkynyl carbamate, stir until the solution becomes transparent; add 0.2% emulsified silicone oil, stir for 20 minutes to obtain the finished product.

[0027] The ferrous metal-specific synthetic cutting fluid with ultra-high lubricating properties prepared in this example has extremely high process adaptability, and can adapt well to different processing temperatures and pressures, so it is suitable for grinding ferrous metal workpieces , milling, turning, tapping, drilling, honing and other processing, the use concentration is 5-10%. It is known from a...

Embodiment 3

[0029] While stirring, add 5% isobutanolamine, 10% diglycolamine, 2% phosphoric acid ester, 3% chlorinated fatty acid, 4% neodecanoic acid, heat to 50-60°C, keep stirring for 30 minutes and then turn off the heating; Gradually add 56.4% of tap water, 1% of tetrasodium EDTA, 3% of organic dibasic acid, 3% of organic tribasic acid, 5% of self-emulsifying ester, 5% of glycerin, 0.2% of benzotriazole, and 2% of morpholine derivatives %, 0.2% butyl iodopropynyl carbamate, stir until the solution is transparent; add 0.2% emulsified silicone oil, and stir for 20 minutes to obtain the finished product.

[0030] The special synthetic cutting fluid for ferrous metals with ultra-high lubricating performance prepared in this embodiment is mainly suitable for cutting and grinding of cemented carbide materials, and the use concentration is 3-6%. Compared with common synthetic cutting fluids on the market, this cutting fluid can achieve the required lubricating effect at a lower concentratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com