A method for preparing low-sugar and low-salt oyster peptides by enzymatically hydrolyzing oyster meat at low temperature

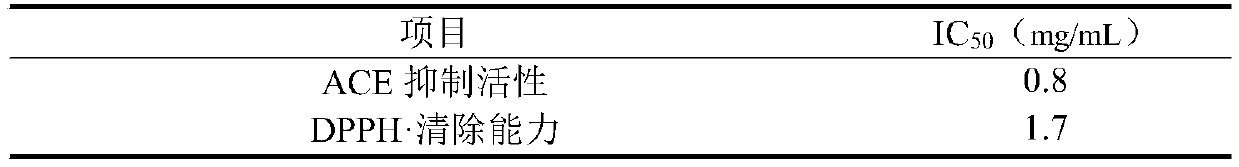

A low-temperature enzymatic hydrolysis and oyster meat technology, which is applied in fish protein components, animal protein processing, food science, etc., can solve the problems of difficult storage, high enzymatic hydrolysis temperature, and high price of protease, and achieve good ACE inhibitory activity , reduce the enzymatic hydrolysis temperature, easy to digest and absorb

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

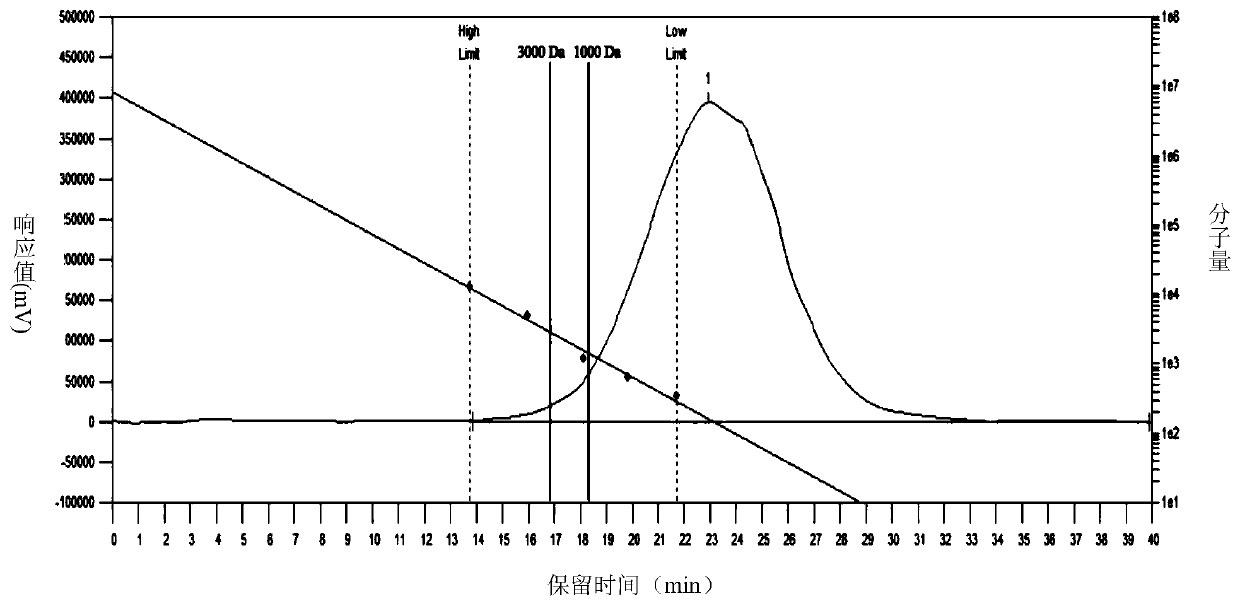

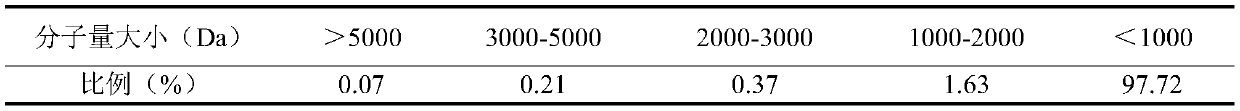

Image

Examples

Embodiment 1

[0030] The preparation of embodiment 1 shrimp head compound enzyme preparation

[0031] 1) Pretreatment of raw materials: Take 5kg of fresh discarded shrimp heads, add 10kg of ice water, mechanically crush and extract, and filter to obtain 10L of filtrate;

[0032] 2) Decolorization and deodorization of ion exchange resin: 10 L of filtrate is adsorbed with domestic 732 type strongly acidic cation exchange resin;

[0033] 3) Spray drying powder: add 4-hexylresorcinol (4-HR) 3g and cyclodextrin 300g to the solution after decolorization and deodorization, dissolve and mix and spray dry powder to get 500g powder, unit enzyme The activity is 2200U / g.

Embodiment 2

[0034] Example 2 Method for preparing low-sugar and low-salt oyster peptides by low-temperature enzymatic hydrolysis of oyster meat

[0035] Raw material pretreatment: take 1 kg of oyster meat after shelling and viscera removal;

[0036] Soaking in decolorizing agent solution: Soak 1kg of oyster meat in 2L of decolorizing agent solution with a mass fraction of 0.3%, that is, the mass of oyster meat and the volume of decolorizing agent solution are 1:2, the soaking time is 0.5h, and the decolorizing agent used is Xiamen Maillard DOFISH-sebaoneng produced by Food Science and Technology Co., Ltd.; the decolorizing agent solution is specifically an aqueous solution of decolorizing agent;

[0037] Repeated soaking in clean water to remove salt: Soak the oyster meat soaked in the decolorizing agent solution in clean water for 20 minutes, so that it is repeatedly soaked in clean water 3 times;

[0038] Hot water leaching to remove sugar: put the oyster meat soaked in clear water in ...

Embodiment 3

[0065] Example 3 Method for preparing low-sugar and low-salt oyster peptides by low-temperature enzymatic hydrolysis of oyster meat

[0066] Raw material pretreatment: take 2kg of oyster meat after shelling and viscera removal;

[0067] Soaking in decolorizing agent solution: Soak 2kg oyster meat in 2L mass fraction of 0.7% decolorizing agent solution, the ratio of oyster meat mass to decolorizing agent solution volume is 1:1, soaking time is 0.8h, and the decolorizing agent used is Xiamen Maillard Food DOFISH-sebaoneng produced by Science and Technology Co., Ltd.; the decolorizing agent solution is an aqueous solution of decolorizing agent;

[0068] Repeated soaking in clean water to remove salt: Soak the oyster meat soaked in the decolorizing agent solution in clean water for 25 minutes, so that it is repeatedly soaked in clean water 4 times;

[0069] Hot water leaching to remove sugar: soak the oyster meat in water at 90°C for 15 minutes;

[0070] Tissue crushing and homo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com