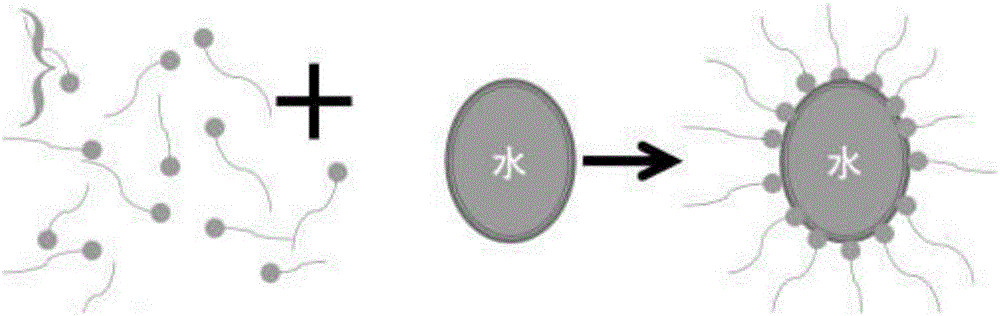

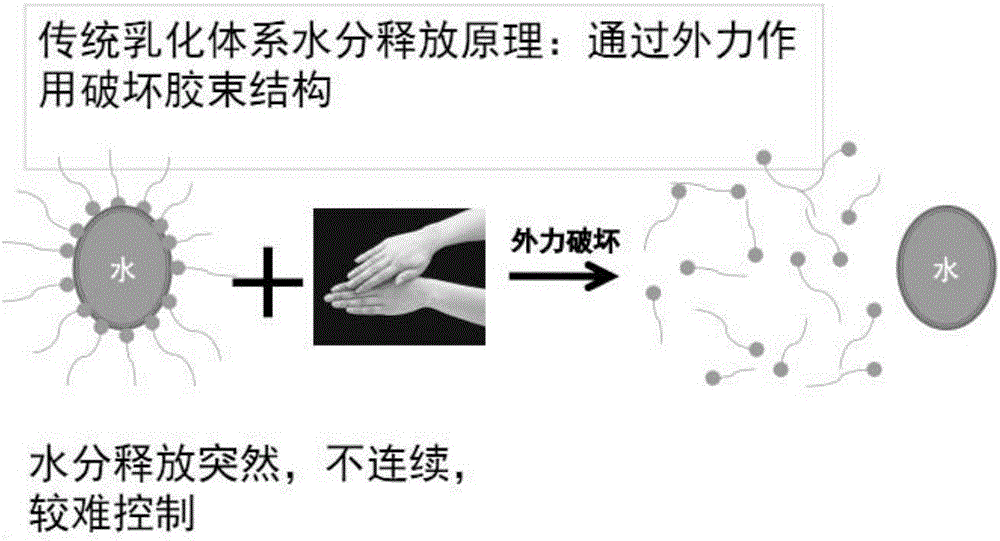

Controllable moisture slow releasing system emulsification composition and preparing method thereof

An emulsified composition and a technology for the composition, applied in cosmetic preparations, preparations for skin care, cosmetics, etc., can solve the problems of high operation process requirements, uncontrollable water output speed, and sudden water release, etc., to expand the scope of application, reduce Skin irritation, increased stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The preparation method of the controlled release system composition described in table 2, its processing step can be expressed as follows:

[0054] 1) Add deionized water, propylene glycol, panthenol, soluble collagen, magnesium sulfate, and water-soluble jojoba oil in component A to the water phase pot in sequence, start stirring (60 rpm), and directly stir evenly;

[0055] 2) Add the diethylhexyl carbonate, tocopheryl acetate, SSG-210SP, Dow Corning 5225C, and phenyl polytrimethicone of component B into the emulsification pot in sequence, and start stirring (50 rpm ),well mixed;

[0056] 3) Adjust the stirring speed of the emulsification pot to 200 rpm, slowly inhale component A through vacuum, and finish the suction in about 10 minutes, turn on the low-speed homogenization (1000 rpm), and homogenize for 10 minutes;

[0057] 4) Mix component C caprylyl glycol, lactic acid, and essence evenly, then slowly add to the emulsification pot, stir (200 rpm) evenly; homogeniz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com