Purification device for oil mist-containing waste gas

A technology for purifying device and exhaust gas, applied in gas treatment, chemical instruments and methods, membrane technology, etc., can solve the problems of easy adhesion of oil mist to the impeller, short service life of filter material, and high cleaning cost, and achieves the benefits of oil mist. And the effect of exhaust gas purification, increased gas-liquid contact area, and improved purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

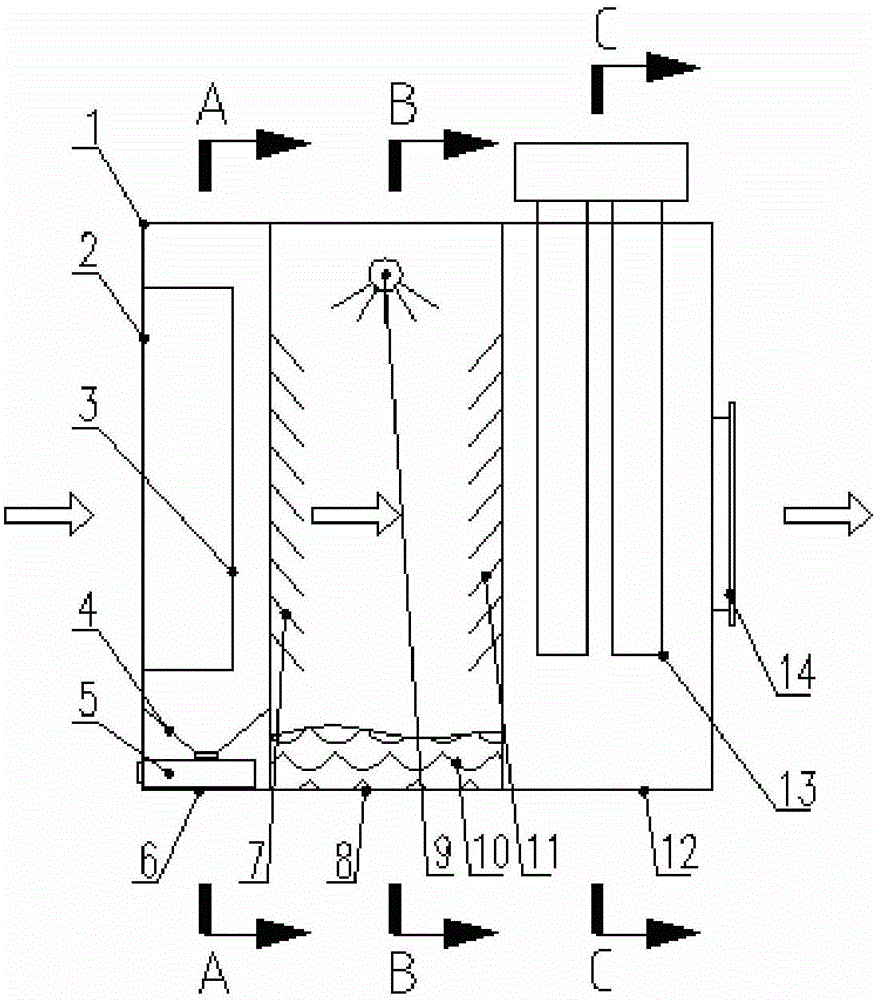

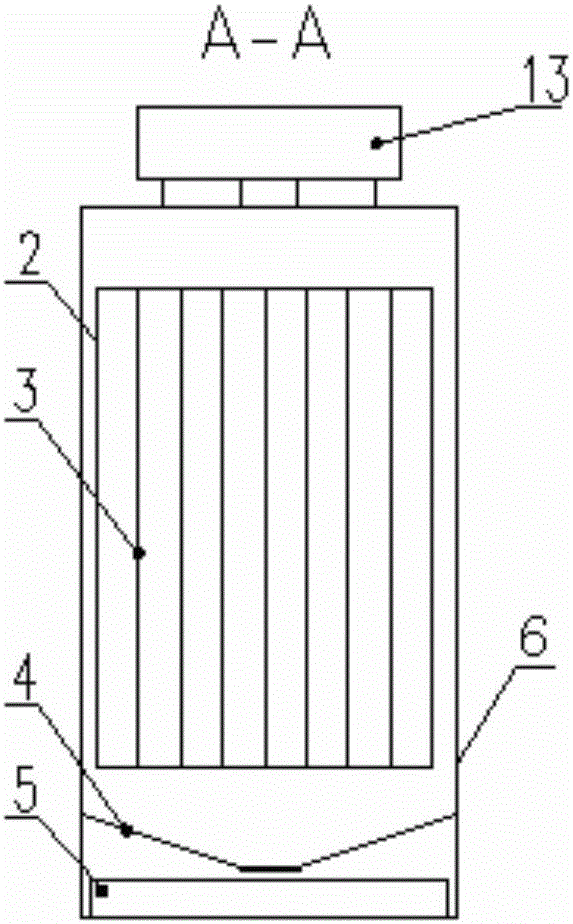

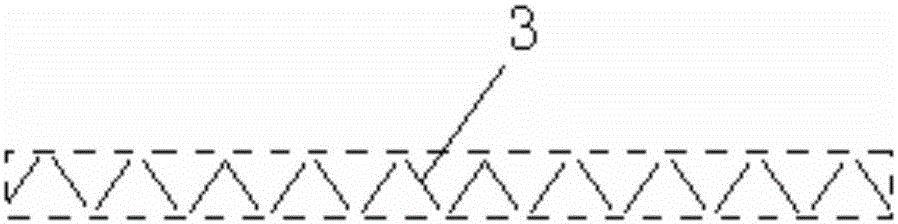

[0039] see Figure 1 to Figure 5 , the purification device for oil mist exhaust gas in the illustration is a preferred embodiment of the present invention, specifically including an outer shell 1, an air inlet 2, an organ-type oil baffle 3, an oil bucket 4, an oil tank 5, and an oil mist recovery section box 6 , inlet baffle 7, micro-bubble purification section box 8, micro-bubble generator 9, circulating fluid 10, outlet baffle 11, high-energy ion purification section box 12, high-energy ion purifier 13, air outlet 14, water inlet pipe 15 , circulating water pump 16 and outlet pipe 17 and other components.

[0040] Specifically, the purification device of this embodiment mainly includes three parts, which are sequentially connected in series: an oil mist recovery section, a microbubble purification section, and a high-energy ion purification section. In the body 8 and the high-energy ion purification section box 12, the oil mist recovery section box 6, the microbubble purifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com