Quick-setting early strength inorganic polymer mortar and production method thereof

A technology of inorganic polymers and polymers, which is applied in the field of building materials, can solve the problems of poor stability, low early strength, and high cost, and achieve the goal of enhancing bonding strength and durability, increasing flexural strength, and increasing shear strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

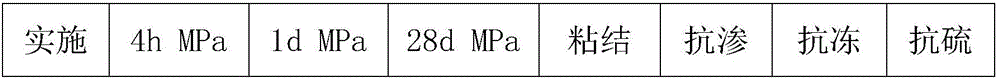

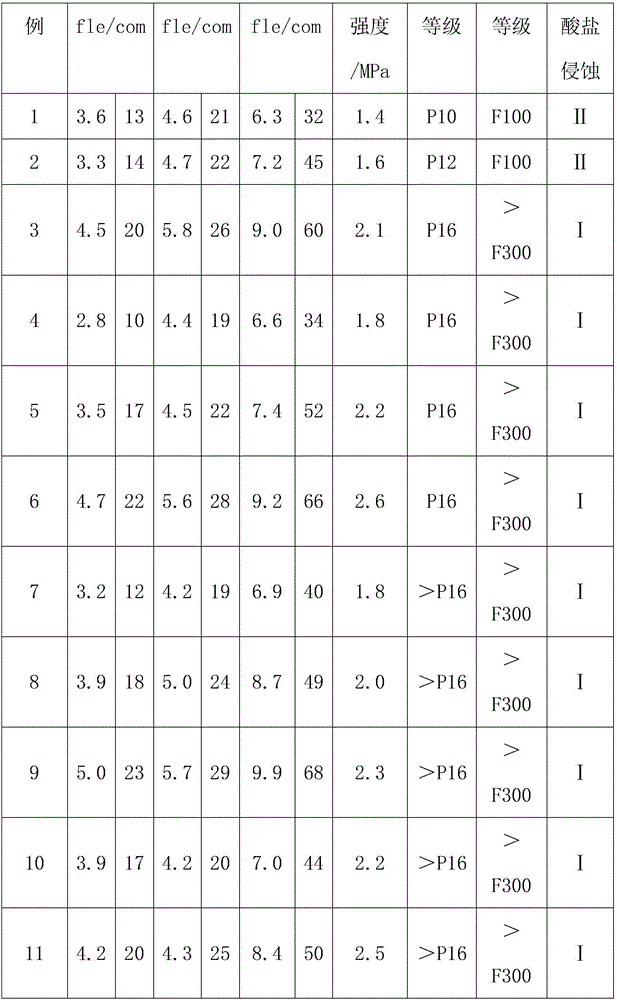

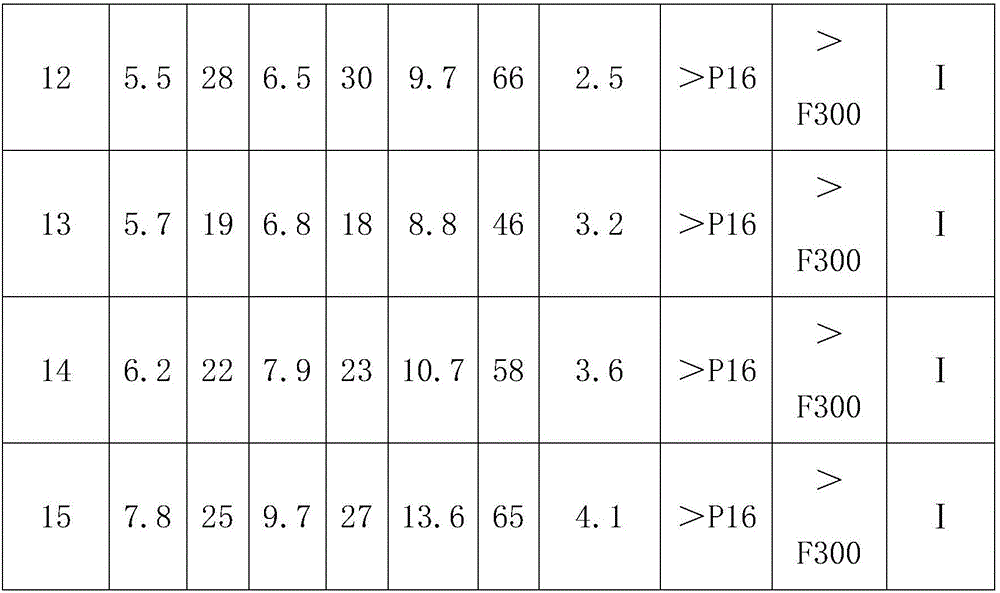

Examples

Embodiment 1

[0023] Example 1 A fast-setting early-strength inorganic polymer mortar, its raw materials are proportioned by mass fraction as follows: 40kg of slag powder, 58kg of prepared quartz sand, 2kg of alkali activator, 0.24kg of high-efficiency water reducer, and 14kg of tap water. Among them, the specific surface area of slag powder is 500m 2 / kg; 20% of quartz sand with 20-40 mesh, 40% of 40-70 mesh, 30% of 70-100 mesh, 10% of 100-150 mesh and SiO 2 The content is between 99% and 99.5%, FeO 3 The content is not higher than 0.005%; the alkali activator is sodium silicate and the mesh number is between 2.4 and 3.3; the high-efficiency water reducer is polycarboxylate water reducer, and the water reducing efficiency is ≥ 13%.

[0024] The preparation method is as follows:

[0025] A. Weigh 2kg of alkali activator and 14kg of tap water, heat to 70°C after mixing, stir slowly, and cool for 20min to obtain an alkali activator solution;

[0026] B. Weigh 40kg of slag powder and 0.24...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com