A kind of synthetic method of lipoic acid intermediate

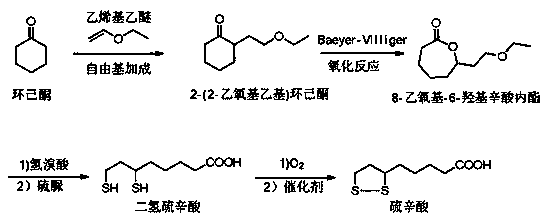

A synthetic method and intermediate technology, applied in the field of preparation of lipoic acid intermediate 2-cyclohexanone, can solve the problems of high cost, high energy consumption, low purity, etc., achieve low cost, high product purity, and reduce distillation steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

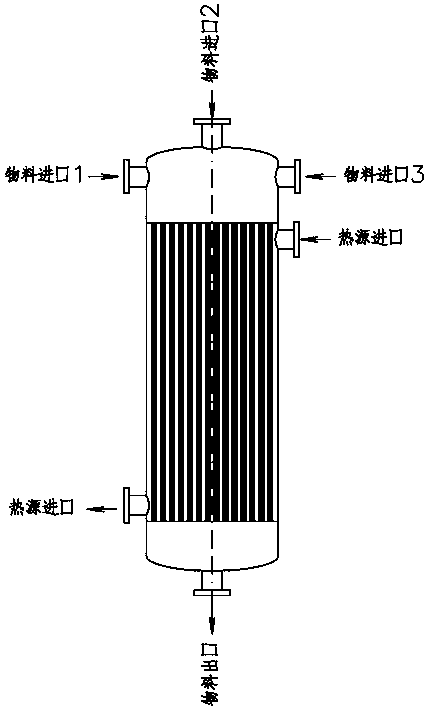

[0025] Add cyclohexanone (50.0kg, 0.51mol) from material inlet 1, add the mixed vinyl ethyl ether (36.8kg, 0.51mol) and hydrogen peroxide (1.7kg, 0.05mol) from material inlet 2, and import 3 Feed 15 mg / L of gaseous ozone, continuously mix and react in the reactor, keep the reaction temperature at 90°C, and keep the residence time for 2 hours, collect the product at the material outlet of the tubular reactor to obtain 2-(2-ethoxyethyl ) Cyclohexanone 76.4kg, purity 96.3%, yield 88.0%.

Embodiment 2

[0027] Add cyclohexanone (50.0kg, 0.51mol) from material inlet 1, add the mixed vinyl ethyl ether (29.6kg, 0.41mol) and hydrogen peroxide (1.7kg, 0.05mol) from material inlet 2, and import 3 Feed 13 mg / L of gaseous ozone, continuously mix and react in the reactor, keep the reaction temperature at 100°C, and keep the residence time for 1.5 hours, collect the product at the material outlet of the tubular reactor to obtain 2-(2-ethoxyethyl ) Cyclohexanone 57.9kg, purity 95.5%, yield 82.9%.

Embodiment 3

[0029] Add cyclohexanone (50.0kg, 0.51mol) from material inlet 1, add the mixed vinyl ethyl ether (40.5kg, 0.56mol) and hydrogen peroxide (1.7kg, 0.05mol) from material inlet 2, and import 3 Feed 14mg / L of gaseous ozone, continuously mix and react in the reactor, keep the reaction temperature at 110°C, and keep the residence time for 1 hour, collect the product at the material outlet of the tubular reactor to obtain 2-(2-ethoxyethyl ) Cyclohexanone 73.8kg, purity 96.1%, yield 85.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com