Ultra-high molecular weight polyethylene-graphene-nickel composite material and preparation method

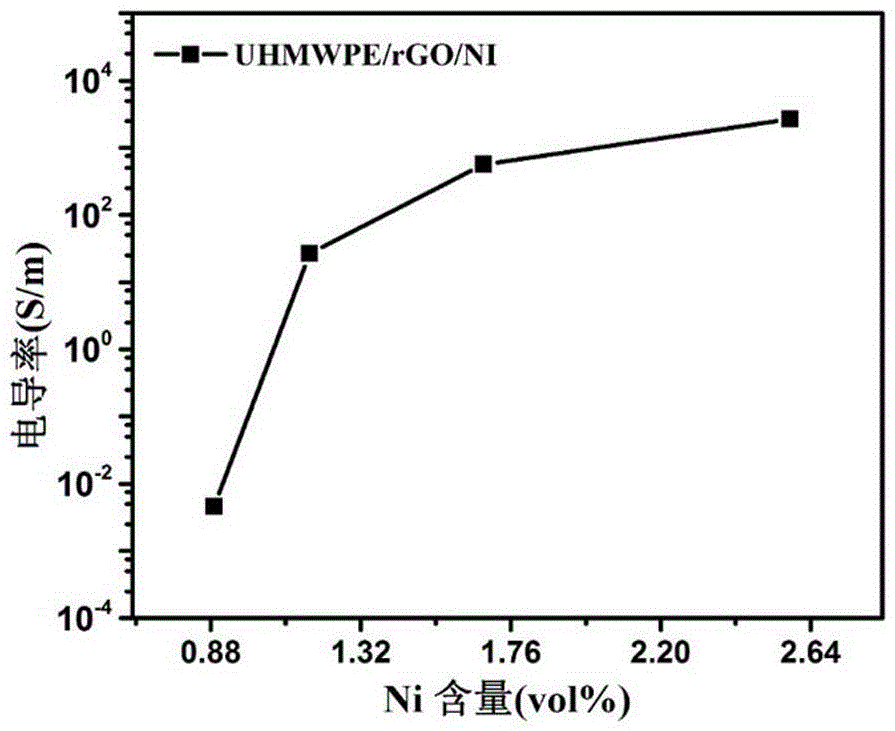

A technology of ultra-high molecular weight and composite materials, which is applied in the field of ultra-high molecular weight polyethylene/graphene/nickel composite materials and its preparation, which can solve the problems of high density, large amount of addition, poor dispersion, etc., and achieve good reproducibility , Conductivity and electromagnetic shielding performance are stable, and the effect of improving conductivity and electromagnetic shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

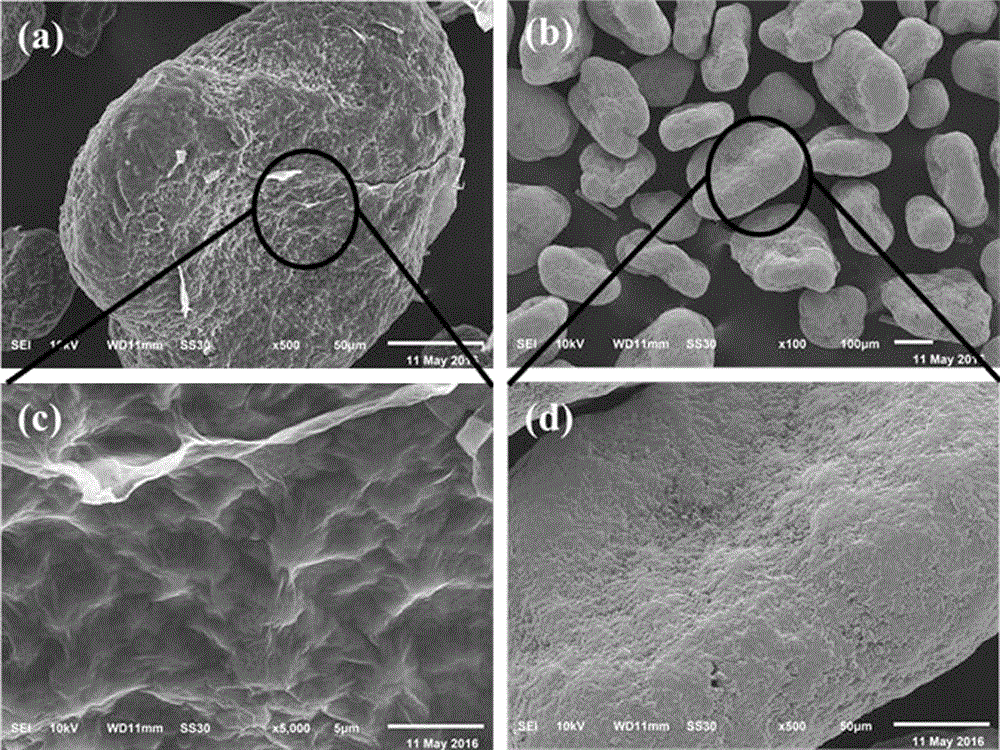

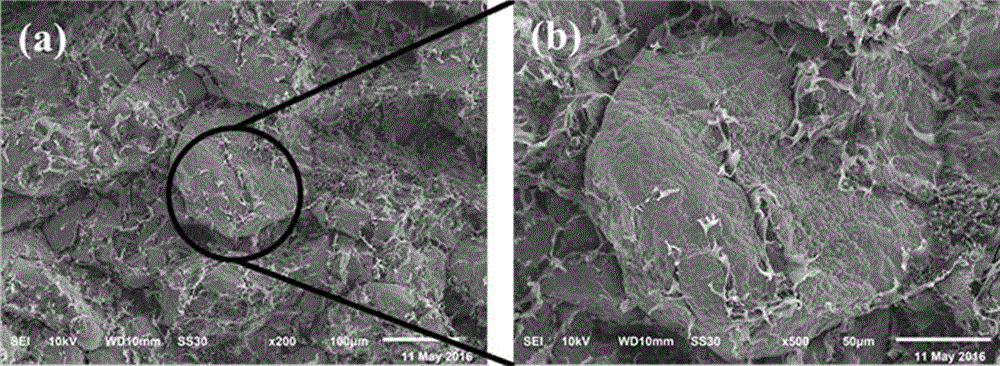

[0022] Disperse graphene oxide and ultra-high molecular weight polyethylene with a volume ratio of 0.1:99.9 into ethanol solution, stir and evaporate at a constant temperature of 90°C, dry the obtained sample, and then pass through a hydrazine hydrate solution at 90°C to reduce it with stirring for 4 hours, and filter , Washing and drying to obtain graphene-coated ultra-high molecular weight polyethylene particles.

[0023] Pretreatment of the surface of graphene-coated ultra-high molecular weight polyethylene particles includes: sensitization: add graphene-coated ultra-high molecular weight polyethylene particles to 100ml of sensitizing solution at 30°C in an ultrasonic bath Stir in medium for 15 minutes, wash; activation: add the sensitized ultra-high molecular weight polyethylene particles to 100ml of activation solution, stir in an ultrasonic water bath at 30°C for 15 minutes, wash and dry for later use.

[0024] The preparation process of sensitizing solution and activation so...

Embodiment 2

[0031] Disperse graphene oxide and ultra-high molecular weight polyethylene with a volume ratio of 0.1:99.9 into ethanol solution, stir and evaporate at a constant temperature of 60°C, dry the obtained sample, stir and reduce it with hydrazine hydrate solution at 80°C for 3h, and filter , Washing and drying to obtain graphene-coated ultra-high molecular weight polyethylene particles.

[0032] Pretreatment of the surface of graphene-coated ultra-high molecular weight polyethylene particles, including: sensitization: add graphene-coated ultra-high molecular weight polyethylene particles to 100ml of sensitizing solution, at 25°C, in an ultrasonic bath Stir in medium for 30 minutes, wash; activation: add the sensitized ultra-high molecular weight polyethylene particles to 100ml of activation solution at a temperature of 30°C, stir in an ultrasonic water bath for 30 minutes, wash and dry for later use.

[0033] The preparation process of sensitizing solution and activation solution is a...

Embodiment 3

[0040] Disperse graphene oxide and ultra-high molecular weight polyethylene with a volume ratio of 0.1:99.9 into ethanol solution, stir and evaporate at a constant temperature of 70°C, dry the obtained sample, stir and reduce with hydrazine hydrate solution at 90°C for 4 hours, and filter , Washing and drying to obtain graphene-coated ultra-high molecular weight polyethylene particles.

[0041] Pretreatment of the surface of graphene-coated ultra-high molecular weight polyethylene particles, including: sensitization: add graphene-coated ultra-high molecular weight polyethylene particles to 100ml of sensitizing solution, at 25°C, in an ultrasonic bath Stir in medium for 60 minutes and wash; activation: add the sensitized ultra-high molecular weight polyethylene particles to 100ml of activation solution, stir in an ultrasonic water bath at 30°C for 60 minutes, wash and dry for later use.

[0042] The preparation process of sensitizing solution and activation solution is as follows:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com