Resin frame, preparation method, and application thereof

A technology of resin and frame, which is applied in the field of photovoltaic materials, can solve the problems of bond performance damage between the adhesive and the aluminum frame, oxidation damage of component grid lines, and influence on the appearance of the aluminum frame, etc., and achieve excellent salt spray corrosion resistance and excellent insulation Pressure resistance, the effect of preventing components from being damaged by lightning strikes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

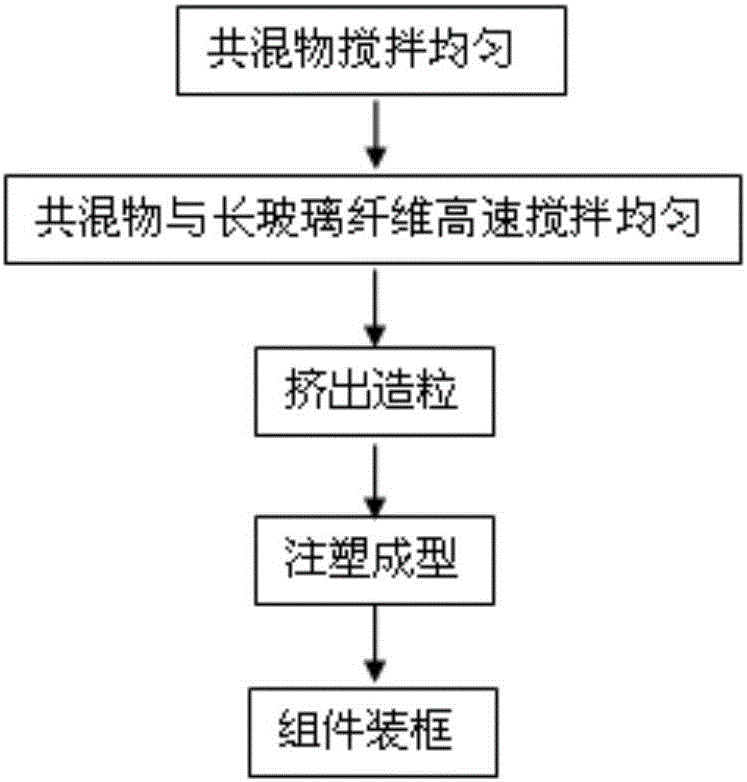

[0034] refer to image 3 : S1, take ABS, PA6, compatibilizer, antioxidant, ultraviolet absorber, wetting agent, light stabilizer according to weight according to the composition component in Table 1, place in mixing container, control mixer speed to be 400r / min, The mixing temperature is 90°C, mix for 5 minutes, and stir to mix evenly.

[0035] S2. Mix the mixture with the long glass fiber material evenly, add it to the extruder to melt and mix and extrude the plastic filamentous substance, and then cut it into plastic particles suitable for ordinary screw injection molding machine according to the size of the required particles, that is, get Glass fiber reinforced ABS / PA6 resin material, from the inlet to the outlet, set the temperature of each section of the screw extruder to be 190°C, 200°C, 210°C, 230°C, 230°C, and the pressure to be 100MPa. Drawing out of the machine, and then cutting into plastic particles suitable for ordinary screw injection molding machines according...

Embodiment 2

[0038] refer to image 3 : S1, take ABS, PA6, compatibilizer, anti-oxidant, ultraviolet absorber, wetting agent, light stabilizer according to weight according to the component in table 1, place in mixing container, control mixer speed to be 500r / min, The mixing temperature is 70°C, mix for 10 minutes, and stir to mix evenly.

[0039] S2. Mix the mixture with the long glass fiber material evenly, add it to the injection molding machine to melt and mix and extrude the plastic filament, and then cut it into plastic particles suitable for ordinary screw injection molding machine according to the size of the required particles, that is, to obtain glass Fiber-reinforced ABS / PA6 resin material, from the inlet to the outlet, set the temperature of each section of the screw extruder to 195°C, 205°C, 215°C, 235°C, 225°C, and the pressure to 100MPa. Machine drawing, and then cut into plastic particles suitable for ordinary screw injection molding machines according to the size of the r...

Embodiment 3

[0042] refer to image 3 : S1, take by weight ABS, PA6, compatibilizer, antioxidant, UV absorber, wetting agent, light stabilizer according to the composition in Table 1, place in a mixing container, control the speed of the mixer to 600r / min, The mixing temperature is 50°C, mix for 15 minutes, and stir to mix evenly.

[0043] S2. Mix the mixture with the long glass fiber material evenly, add it to the injection molding machine to melt and mix and extrude the plastic filament, and then cut it into plastic particles suitable for ordinary screw injection molding machine according to the size of the required particles, that is, to obtain glass Fiber-reinforced ABS / PA6 resin material, from the inlet to the outlet, set the temperature of each section of the screw extruder to 200°C, 210°C, 220°C, 230°C, 220°C, and the pressure to 100MPa. Machine drawing, and then cut into plastic particles suitable for ordinary screw injection molding machines according to the size of the required ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com