Material with effects of insulating sound and reducing noise and preparation method of material

A technology of sound insulation and noise reduction, silicone rubber, applied in the field of functional materials, to achieve the effect of simple manufacturing process, simple process and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

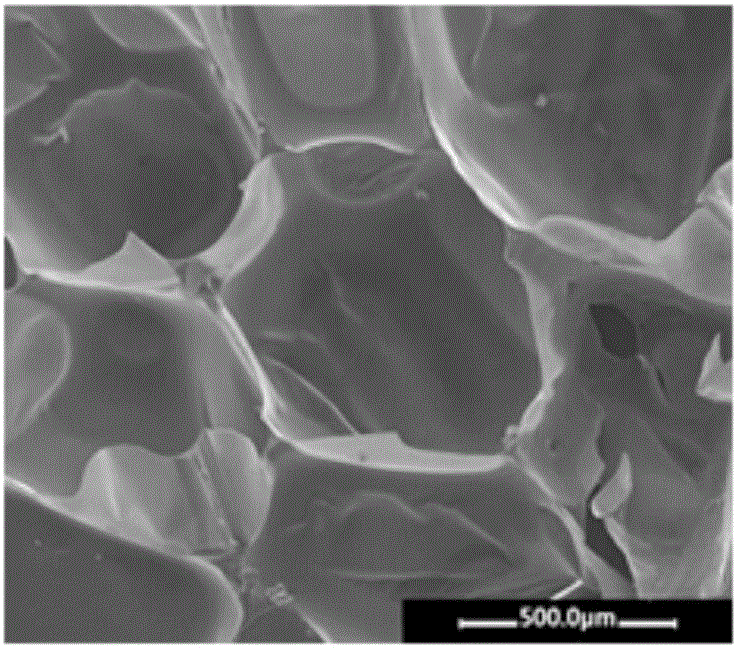

[0028] In the embodiment of the present invention, the preparation method of the silicone rubber cracking product includes: adding sulfuric acid solution to the silicone rubber for digestion. When the silicone rubber was digested at 130°C for 20 minutes in a microwave digestion tank, the silica gel was basically cracked completely, and the resulting cracked product was mainly a mixture of dimethylepoxysilane [(CH 3 ) 2 SiO] n (n = 4-20) and its cracking residue. Wherein, the mass percent concentration of the sulfuric acid solution is 20-40%; the silicone rubber is the shed of the decommissioned high-voltage insulator after being sheared and peeled off, and is then washed with acid, alkali, and water under ultrasonic conditions. Wash for about 15 minutes, wash away the stains on the surface of the shed, and then dry it at 105°C. After it is first crushed into crumbs by a shear crusher, it is placed in a grinder and crushed at 3600 rpm for 5 minutes. , to obtain 10-200 mesh si...

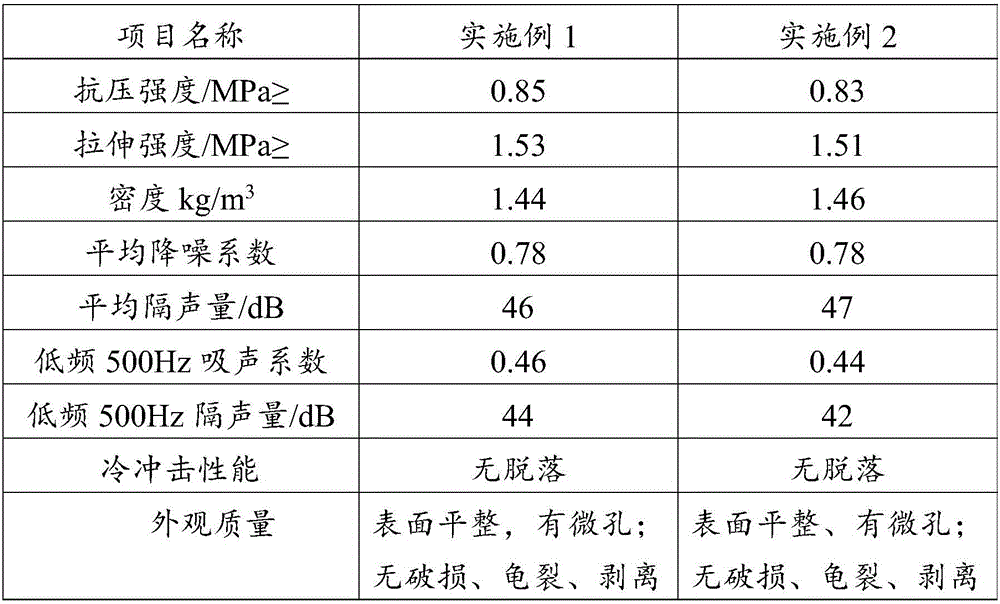

Embodiment 1

[0038] The present invention is applied to the sound insulation and noise reduction material of low frequency noise, and its preparation method is as follows:

[0039] (1) The silicone rubber sheds of decommissioned high-voltage insulators that have been sheared and peeled off are ultrasonically cleaned with clean water for 15 minutes to remove the surface stains and then dried at 105°C. After being crushed by a shearing crusher, they are crushed in a pulverizer for 5 minutes. After passing through a vibrating sieve for 10 minutes, take a 40-mesh sieve to get the silicon rubber powder under the sieve.

[0040] (2) Weigh 10g of the insulator silicone rubber powder described in (1), add 8ml of sulfuric acid with a mass concentration of 30%, and digest it in a microwave digestion tank at 130°C for 20 minutes to obtain the cracked product, mainly dimethylcyclo Oxydisilane (CH 3 ) 2SiO]n (n=4-20) mixture and pyrolysis residue, set aside;

[0041] (3) Preparation of polycarbonate...

Embodiment 2

[0046] (1) Weigh 200g of the silicon rubber powder in Example 1, add 150ml of sulfuric acid with a mass concentration of 30%, and digest the cracked product obtained in a microwave digestion tank at 130°C for 20 minutes, mainly dimethyloxidisilane (CH 3 ) 2 SiO]n (n=4-20) mixture and pyrolysis residue, set aside;

[0047] (2) Preparation of polycarbonate: get 40.0g polycarbonate and heat to 180°C to obtain polycarbonate in molten state, set aside;

[0048] (3) Weigh 15.0 g of aluminum oxide and 13.0 g of silicon oxide to uniformly form a powder with a particle size of 200-300 microns.

[0049] (4) Preparation of composite slurry: add the decommissioned insulator silicone rubber cracking product, silicon oxide and aluminum oxide to the polycarbonate obtained in step 1) according to the above weight ratio, keep warm and stir under the temperature condition of 110 ° C Homogenize for 5 minutes to obtain a composite slurry;

[0050] (5) Preparation of sound insulation and noise...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com