Stable, high-transparent and permanently-smooth PU lusterless top-coat with gloss and preparation method thereof

A high-stable and clear topcoat technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve problems such as poor transparency, uneven gloss, and oldness of the paint film, and achieve permanent smoothness of the coating and smooth paint film Smooth and transparent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

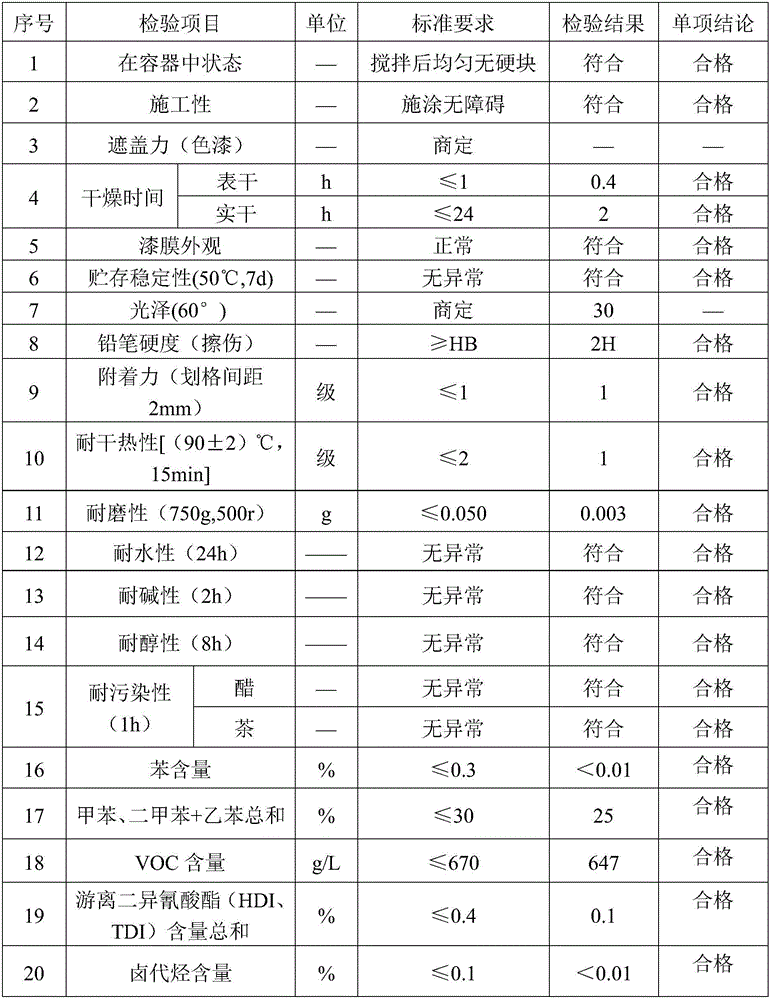

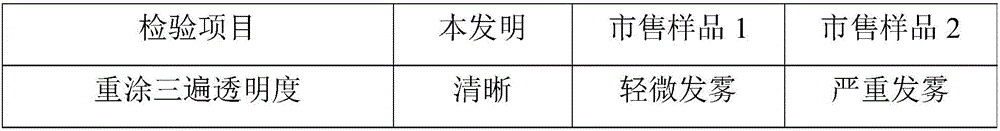

Examples

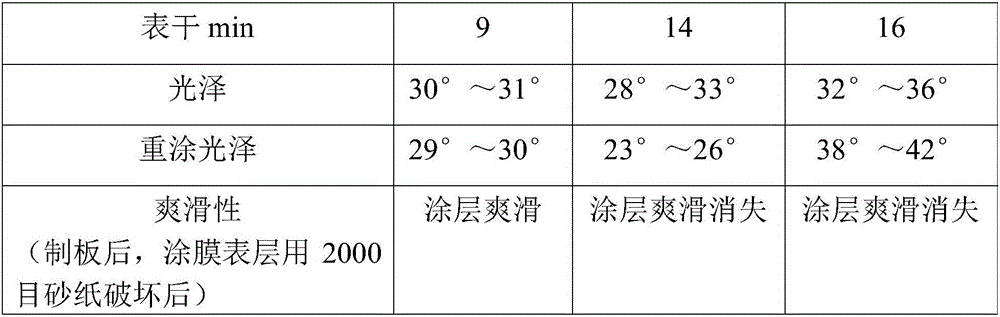

Embodiment 1

[0033] Preparation of component A: Add 43% of short oil alkyd resin, 22% of coconut oil alkyd resin, 0.7% of anti-settling slurry, 0.8% of modified polyurethane polymer dispersant, silicone fluid Leveling agent 0.2%, defoamer (foam breaking polymer and polysiloxane solution) 0.3% and MIBK 3%, stir well at 600 rpm, then add polytetrafluoroethylene at 600 rpm 0.5% ethylene wax powder and 0.2% ED-30 matte powder, stir and disperse at 1200 rpm for 15 minutes until the fineness is ≤25UM, then add 7% nitrocellulose solution with 50% solid content, 15% PE matte wax slurry and Ethyl acetate 2.5%, stir at 800 rpm until uniform, and finally adjust the viscosity to 1400mpa.s / 25°C with 4.8% butyl acetate, and set aside;

[0034] Preparation of Component B: Add 19.3% of TDI curing agent, 5% of HI-100 solvent-free curing agent, 12% of MIBK, 10% of MEK and n-butyl acetate to 45% of 1451 bright trimer curing agent by weight percentage 8.7%, stir evenly, seal and set aside;

[0035] Preparat...

Embodiment 2

[0038] Preparation of component A: Add 47.9% of short oil alkyd resin, 21% of coconut oil alkyd resin, 0.8% of anti-settling slurry, 1.0% of modified polyurethane polymer dispersant, and silicone fluid into the dispersion tank in order by weight percentage Leveling agent 0.4%, defoamer (foam breaking polymer and polysiloxane solution) 0.4% and MIBK 2.8%, stir at 700 rpm until uniform, then add polytetrafluoroethylene at 700 rpm 0.4% ethylene wax powder and 0.8% ED-30 matte powder, stir and disperse at 1300 rpm for 12 minutes to fineness ≤ 25UM, then add 7% nitrocellulose solution with 50% solid content, 9% PE matte wax slurry and 3% ethyl acetate, stir at 900 rpm until uniform, and finally adjust the viscosity to 1700mpa.s / 25°C with 5.5% butyl acetate, and set aside;

[0039] Preparation of component B: Add 16% of TDI curing agent, 5% of HI-100 solvent-free curing agent, 12% of MIBK, 10% of MEK and n-butyl acetate to 46% of 1451 bright trimer curing agent by weight percentage ...

Embodiment 3

[0043] Preparation of component A: Add 50% of short oil alkyd resin, 19% of coconut oil alkyd resin, 1% of anti-settling slurry, 1.2% of modified polyurethane polymer dispersant, silicone fluid Leveling agent 0.5%, defoamer (foam breaking polymer and polysiloxane solution) 0.5% and MIBK 2%, stir at 800 rpm until uniform, then add polytetrafluoroethylene at 800 rpm 0.3% ethylene wax powder and 1% ED-30 matte powder, stir and disperse at 1500 rpm for 10 minutes to fineness ≤ 25UM, then add 7% nitrocellulose solution with 50% solid content, 13.2% PE matte wax slurry and 2% ethyl acetate, stir at 1000 rpm until uniform, and finally adjust the viscosity to 1000mpa.s / 25°C with 2.3% butyl acetate, and set aside;

[0044] Preparation of component B: Add 12% of TDI curing agent, 5% of HI-100 solvent-free curing agent, 12% of MIBK, 10% of MEK and n-butyl acetate to 48% of 1451 bright trimer curing agent by weight percentage 13%, stir evenly, seal and set aside;

[0045] Preparation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com