Linear detector packaging structure capable of suppressing stray light and evening light flux and realization method

A packaging structure and detector technology, applied in measuring devices, optical radiation measurement, electric radiation detectors, etc., can solve the problems of difficulty in developing super-large light windows, inconsistent luminous flux, etc., reduce the difficulty of optical processing, simplify the difficulty of preparation, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

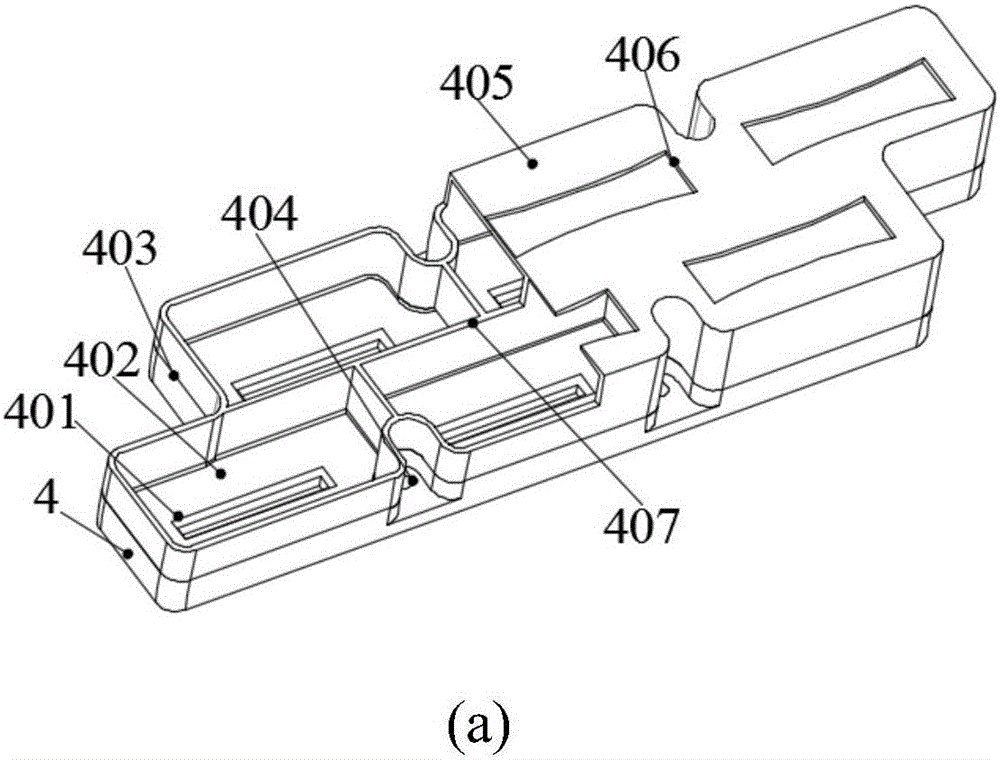

[0071] Below join accompanying drawing to be described in further detail to the embodiment of the present invention in embodiment:

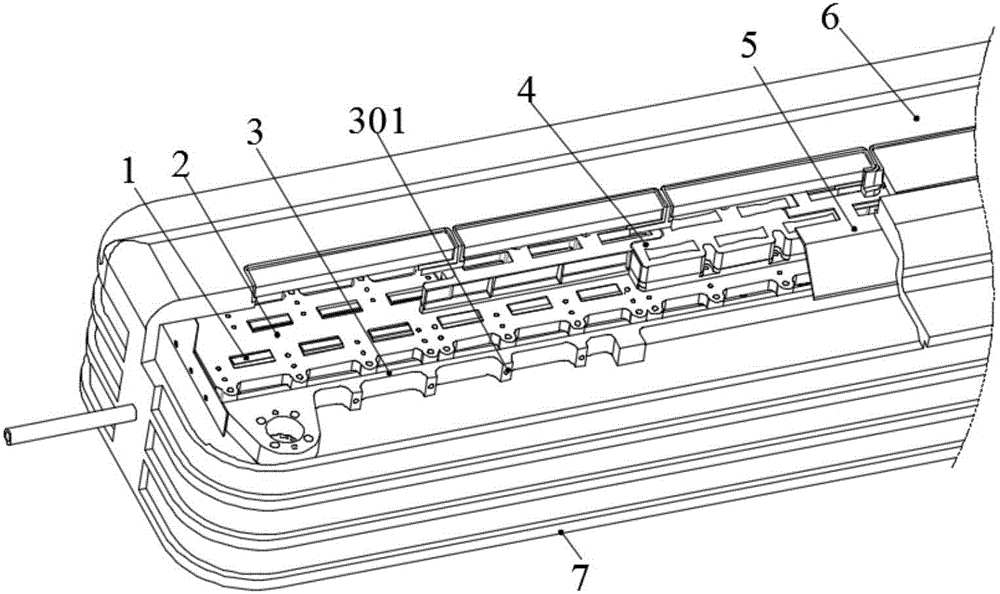

[0072] This embodiment is a package structure of 30000 linear array detectors used for stray light suppression and luminous flux uniformity, as attached figure 1 As shown, its main implementation method is as follows:

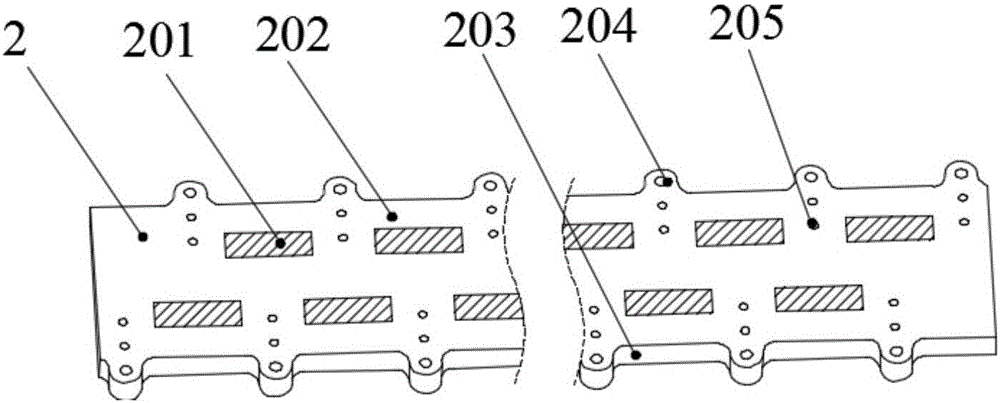

[0073] 1) The spliced linear detector 1 is composed of 30 small-scale infrared detectors spliced in the shape of "pin" and glued and solidified on the detector spliced substrate 2 . The splicing substrate 2 of the detector is a rectangular plate-shaped structure, which is made of Kovar material. During the process of machining and forming, it undergoes 10 times of liquid nitrogen shocks, and the cooling rate is 4°C / s for metallographic pretreatment and stress release. The sub-processing repair makes the flatness and parallelism of the upper and lower surfaces of the spliced substrate 2 of the detector meet the requirement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com