A heavy-duty recirculating ball dual-mode electric power steering device

A technology of electric power steering and torque sensor, which is applied in the direction of electric steering mechanism, power steering mechanism, steering mechanism, etc., and can solve the problem of damage to gear fan shaft steering nut and other components, high structural strength requirements of key components, and difficult system matching, etc. problems, to achieve the effects of simplifying the structure, improving processing efficiency and processing quality, and facilitating flexible layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0060] In this article, if there is no special explanation, when it comes to formulas, " / " means division, and "×" and "*" mean multiplication.

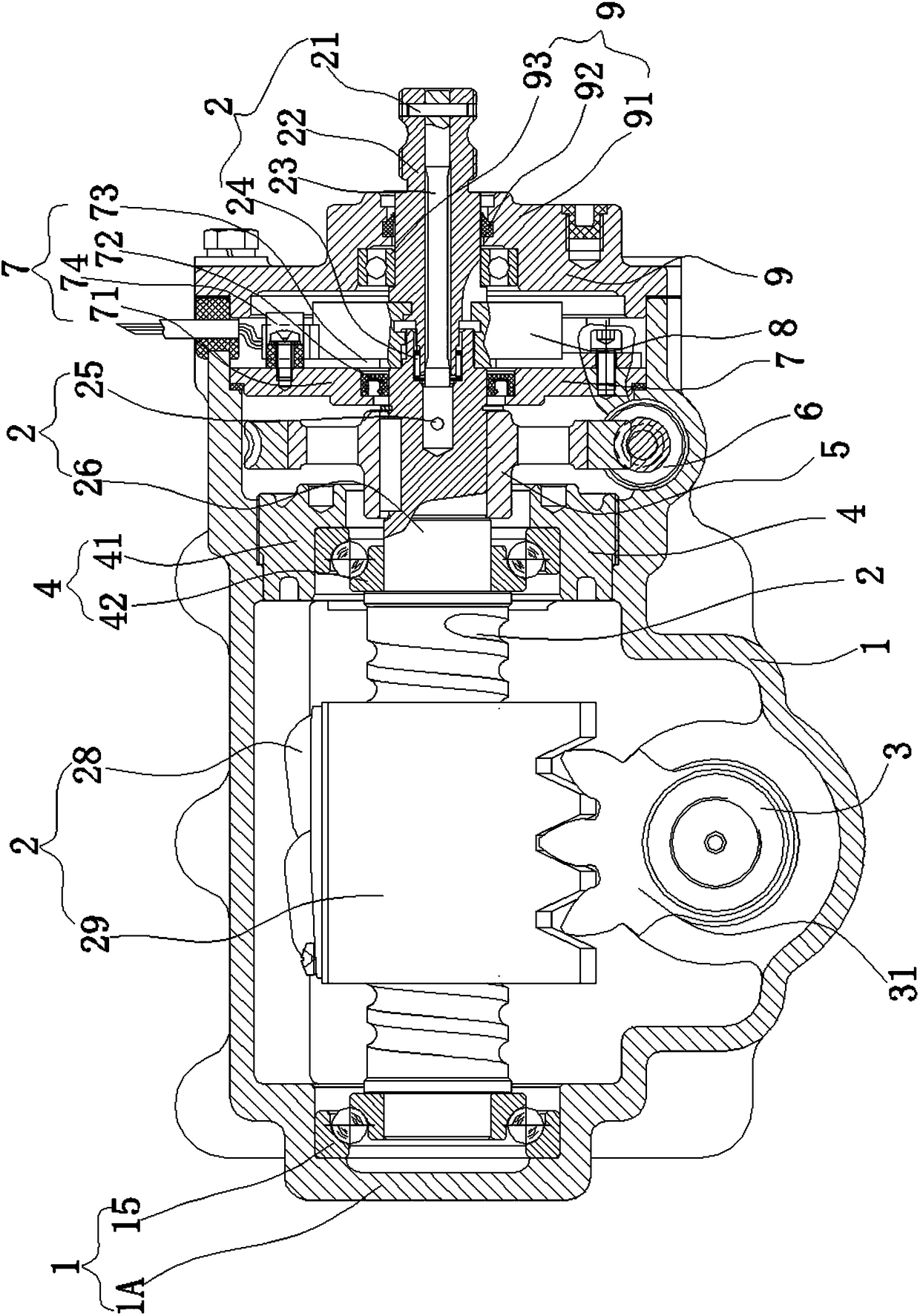

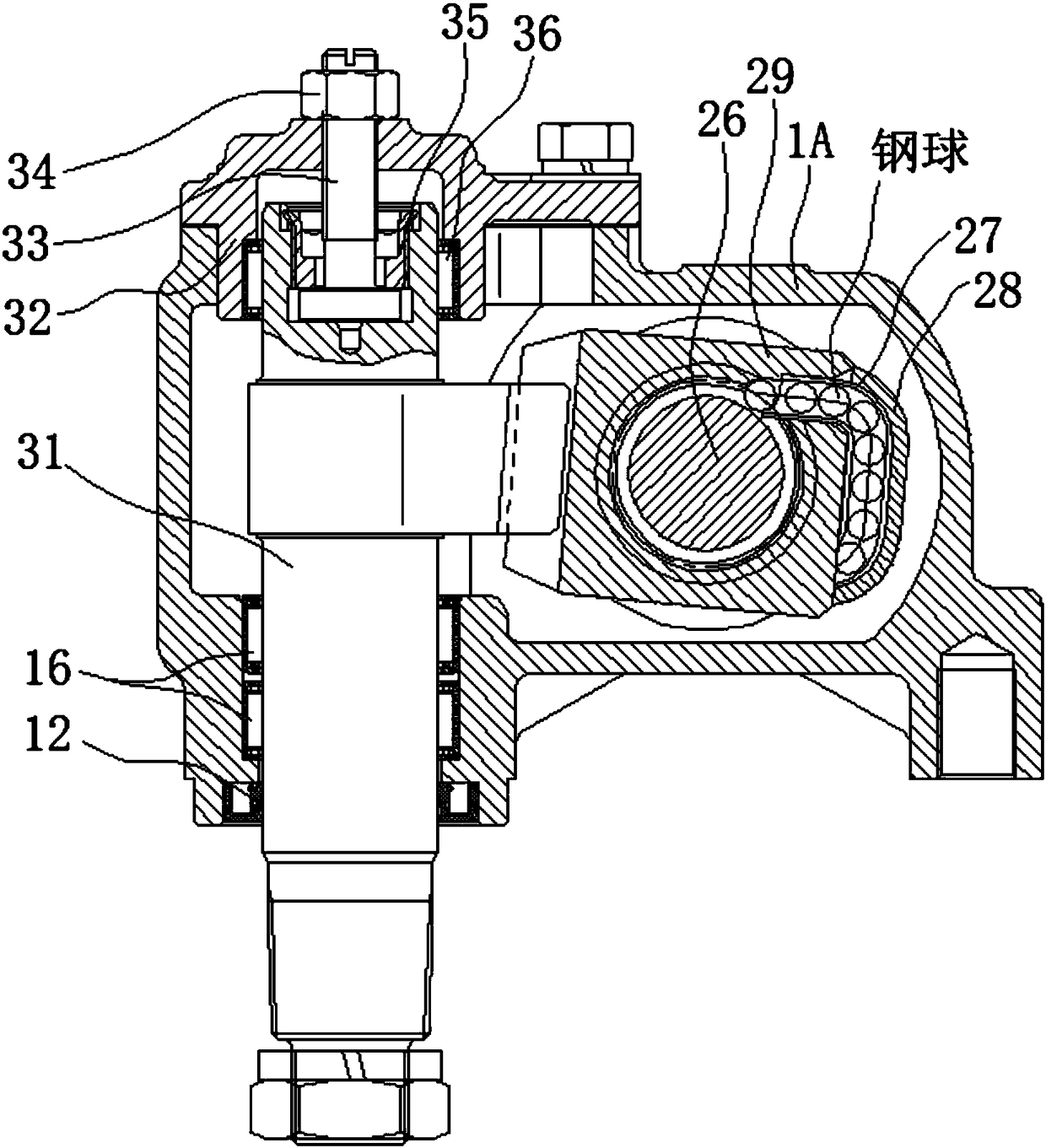

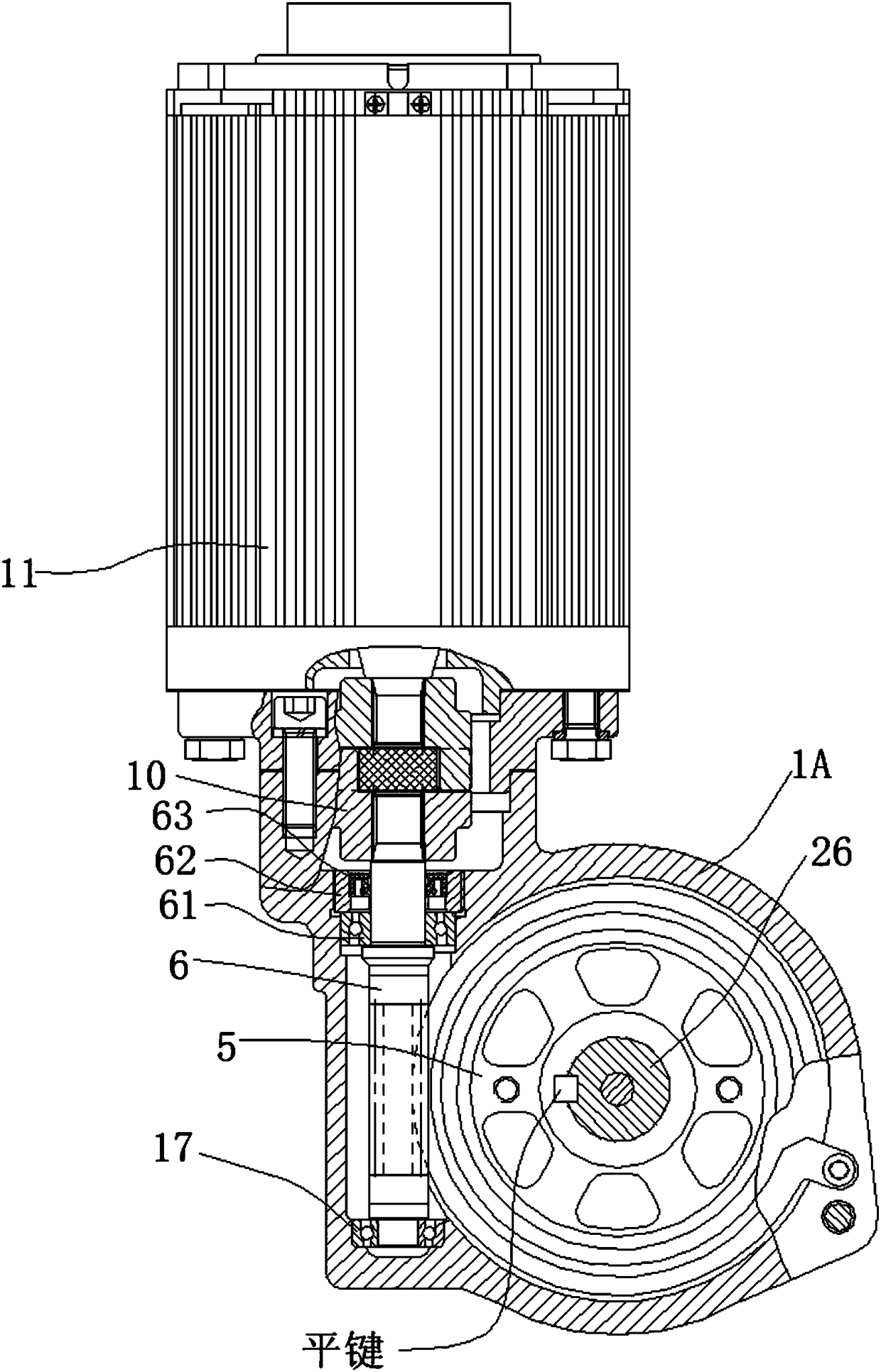

[0061] In order to solve the problems of the prior art, the present invention provides a heavy-duty recirculating ball type dual-mode electric power steering device, such as Figure 1-Figure 3 As shown, it is characterized in that it includes: housing assembly 1, input shaft and screw assembly 2, gear fan shaft assembly 3, support seat assembly 4, worm gear 5, worm screw 6, inner end cover assembly 7, Angle torque sensor 8, outer end cover assembly 9, plum blossom connection sleeve assembly 10, motor assembly 11;

[0062] The inside of the housing assembly is horizontally provided with a cavity with one end closed and one end open. The input shaft and screw assembly 2 are installed in the cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com