High-temperature-resistant low-filtration retaining wall water-based drilling fluid

A technology of water-based drilling fluid and high temperature resistance, which is applied in the field of petroleum drilling, and can solve the problem of low efficiency, high cost, and failure to meet the requirements of drilling fluid density, temperature, rheology, lubricity, inhibition, and water loss. In order to improve drilling speed, suppress formation slurry and improve wellbore stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Specific experimental steps:

[0043] (1) Prepare bentonite slurry, stir well, and let stand for 24 hours;

[0044] (2) Stir the bentonite slurry at a high speed of 10000r / min, and slowly add zwitterionic polymers, quaternary ammonium polymers, amide cationic polymers, cationic organic quaternary ammonium salts, and carboxysulfonic acid copolymers in sequence during the stirring process , sulfonated asphalt, vegetable oil lubricant and weighting agent; in the process of adding the above-mentioned medicines, adjust the pH to 10-11 with a 20% sodium hydroxide aqueous solution after each addition of a medicine, and then stir for 20 minutes. Then add the next drug until the slurry preparation is completed.

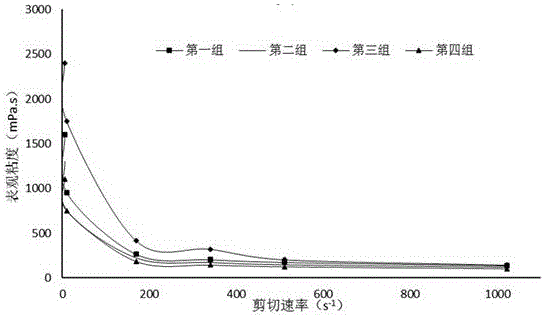

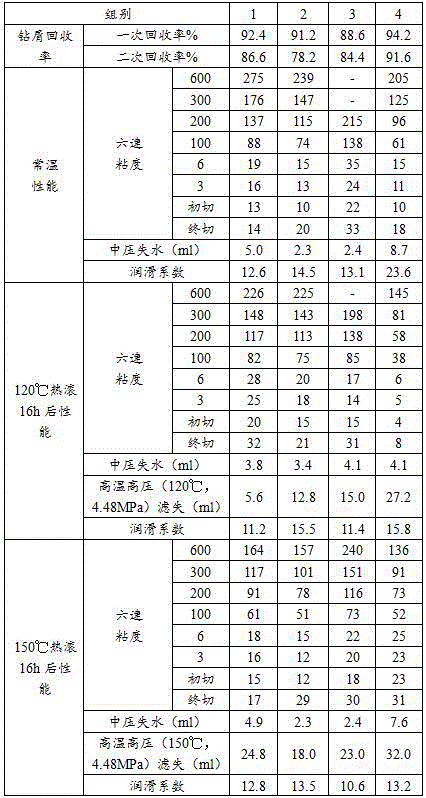

[0045] In the above-mentioned experimental procedures, the applicant has done four groups of experiments in total, and the fourth group added sodium chloride to test the salt pollution resistance of the drilling fluid. The addition amount of each component of each gro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com