Combined smelting method for crude copper

A smelting method and blister copper technology, which is applied in crucible furnaces, electric furnaces, rotary drum furnaces, etc., can solve the problems of long production cycle, low thermal efficiency, high energy consumption, etc., and achieve improved efficiency, compact furnace space, and high heat transfer efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

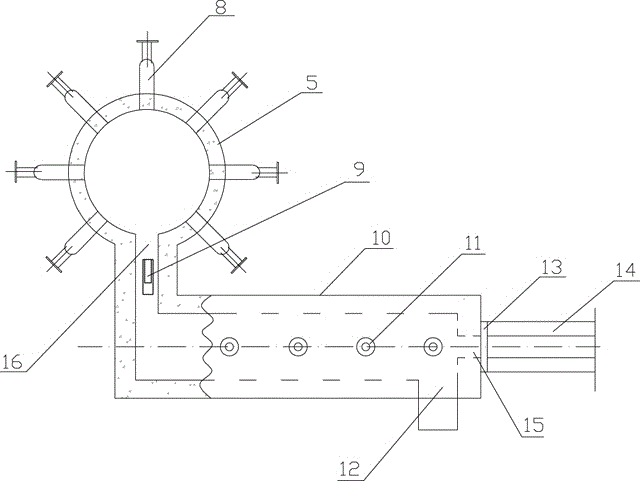

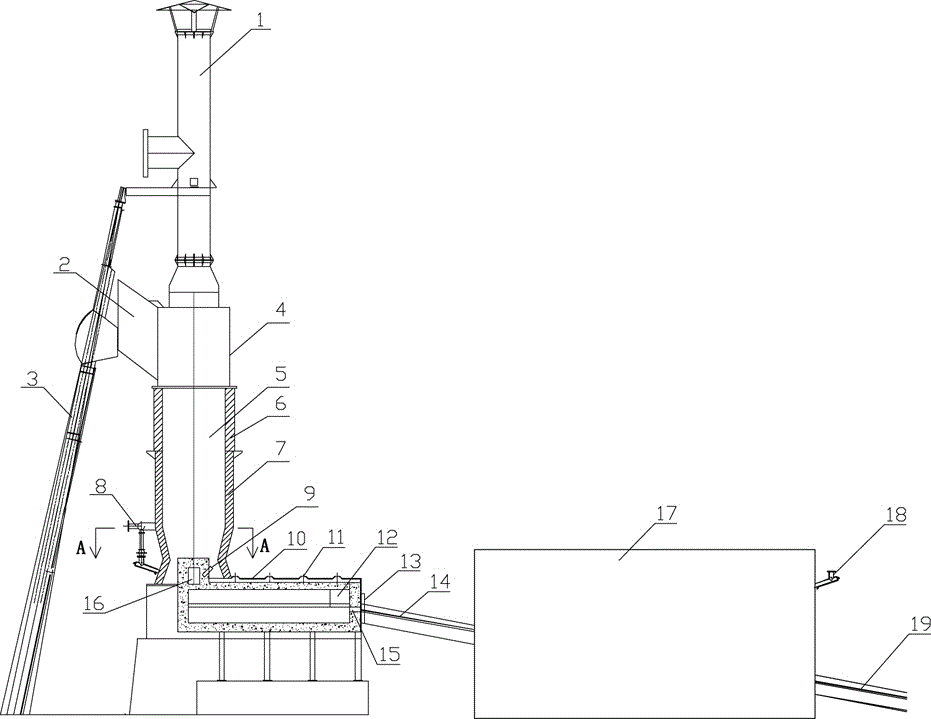

[0052] Applying the present invention to the combined smelting method of blister copper is that the blister copper is first sent into a special flame furnace for melting, and then flows into a fixed anode furnace 17 for oxygen-reducing refining, and the combined smelting of the two furnaces realizes continuous casting of the anode plate; the special flame furnace (see figure 1 , 2 ) has a vertical furnace body 5, a feeding section 4 is provided on the top of the furnace body 5, a feeding port 2 is opened, and a mechanical lifting feeding device 3 is equipped outside (specifically, a winch lifting device is selected), and a chimney 1 is arranged above the feeding section 4 , the lower part of the furnace body is provided with a plurality of burners 8, the furnace lining in the furnace body 5 is composed of two sections, the upper section 6 is a silicon carbide lining, and the lower section 7 is a magnesia-chromium lining; and beside the furnace body 5 A sealed copper liquid cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com