High-strength super-wear-resisting copper alloy and preparation method thereof

A copper alloy, ultra-wear-resistant technology, applied in the field of metallurgy, can solve problems such as short working life, large economic burden, and high price of beryllium copper, and achieve the effects of excellent mechanical properties, grain refinement, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

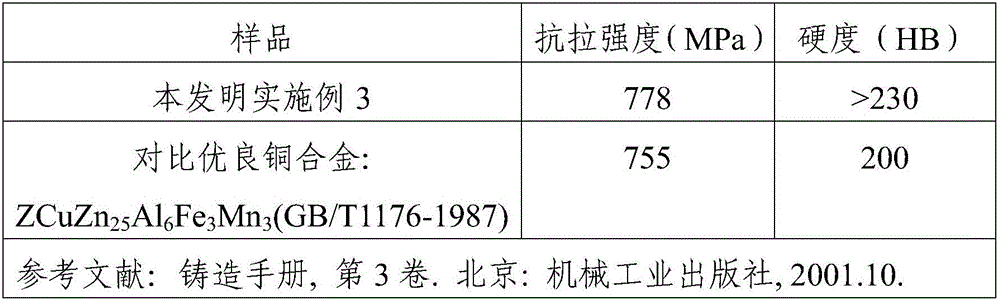

Examples

preparation example Construction

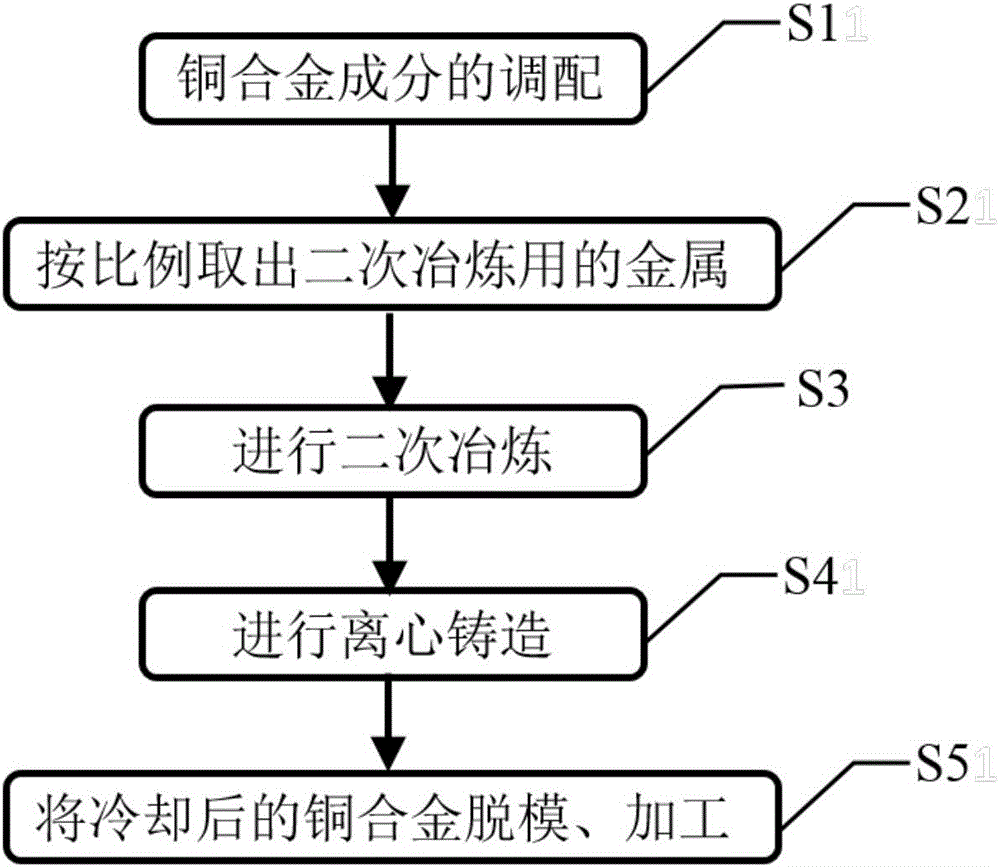

[0029] see figure 1 , the preparation method of the high-strength super wear-resistant copper alloy of the present invention, the specific implementation steps are as follows:

[0030] S1. Take each furnace as a unit, use an electronic scale with an accuracy of ≤1g to weigh out the weight of each electrolytic metal required.

[0031] S2. Take out the metals for secondary smelting from the above metals in proportion, and then put other remaining metals into the smelting furnace for smelting until they are completely melted.

[0032] S3. Putting the taken out metal into the above-mentioned molten metal that is completely melted, and performing secondary smelting until it is completely melted.

[0033] S4. Cast the molten copper alloy into a mold, and then put it into a vertical centrifuge for centrifugal casting. The centrifuged copper alloy has no casting defects such as pores, sand holes, and looseness, which improves the compactness of the casting and enhances the comprehen...

Embodiment 1

[0036] The chemical composition of the high-strength super wear-resistant copper alloy in this embodiment is: the chemical composition of the copper alloy is: Cu 55%, Al 2%, Fe 0.5%, Mn 0.2%, and the rest is Zn.

Embodiment 2

[0038] The chemical composition of the high-strength super wear-resistant copper alloy in this embodiment is: the chemical composition of the copper alloy is: Cu 65%, Al 6%, Fe 5%, Mn 3%, and the rest is Zn.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com