A kind of four-silver low-radiation energy-saving window film and preparation method thereof

A low-emission and window film technology, applied in the field of four-silver low-emission energy-saving window film and its preparation, can solve the problems of large-scale promotion of unfavorable products, rare grass-green window film, poor heat insulation effect, etc., and achieve the best visible light transmission High efficiency, improvement of color cast effect, long-lasting heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings. Wherein, the same parts adopt the same reference numerals.

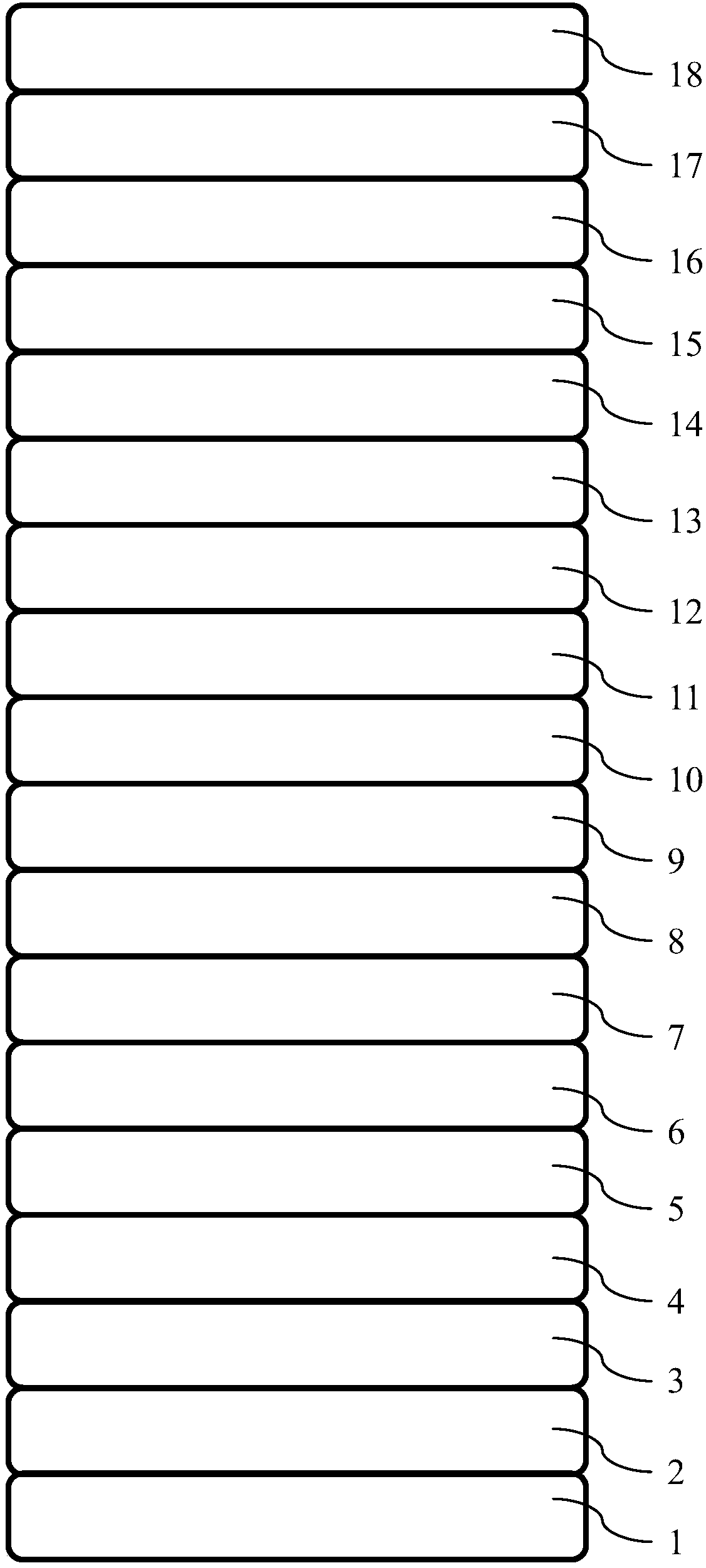

[0048] Such as figure 1 The schematic diagram of the layer structure of the four-silver low-radiation energy-saving window film of the present invention is shown, the film layer structure from the inside to the outside is: flexible transparent PET substrate layer 1, the thickness is 23 microns to 50 microns, and its visible light transmittance is ≥ 89 %, haze≤1.5, preferred thickness is 23 microns; the first high refractive index layer 2 has a thickness of 28nm to 30nm and a refractive index of 2.36, and the first high refractive index layer 2 is made of Nb 2 o 5 Composition, the preferred thickness is 29nm; the first metal oxide layer 3, the thickness is 3nm~6nm, the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com