Energy-saving type electric bicycle hub motor

A technology of electric bicycles and hub motors, applied in the field of electric motors, can solve the problems of motor vibration hysteresis, difficulty in limiting coil displacement, poor magnetic field concentration, etc., and achieve the effects of increasing mileage, enhancing climbing ability, and ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Disk-type coreless DC motor, the winding is composed of 6 coils 20, the radial diameter of the coil 20 is D=32mm, the height is 10.0mm, the copper enameled wire diameter is 0.67mm, the radial length of the triangular hollow is 9.6mm, and 8 first The average value of the inner and outer diameters of the permanent magnet 21 unit is 68mm, the axial height is 6mm, and the radial length is 20mm. °, 41°, 38° for comparison test; Figure 11 is the torque and efficiency curve, a is the torque and efficiency curve when the central angle of the permanent magnet is 45°, b is the torque and efficiency curve when the permanent magnet central angle is 41°, c is the permanent magnet central angle is 38° When the torque and efficiency curves, from Figure 11 From the torque efficiency curve shown, the highest efficiencies of the three motors are 83.8%, 83.1%, and 80.6%, respectively. After leaving a gap between two adjacent permanent magnet units, the effect on the motor efficiency is...

Embodiment 2

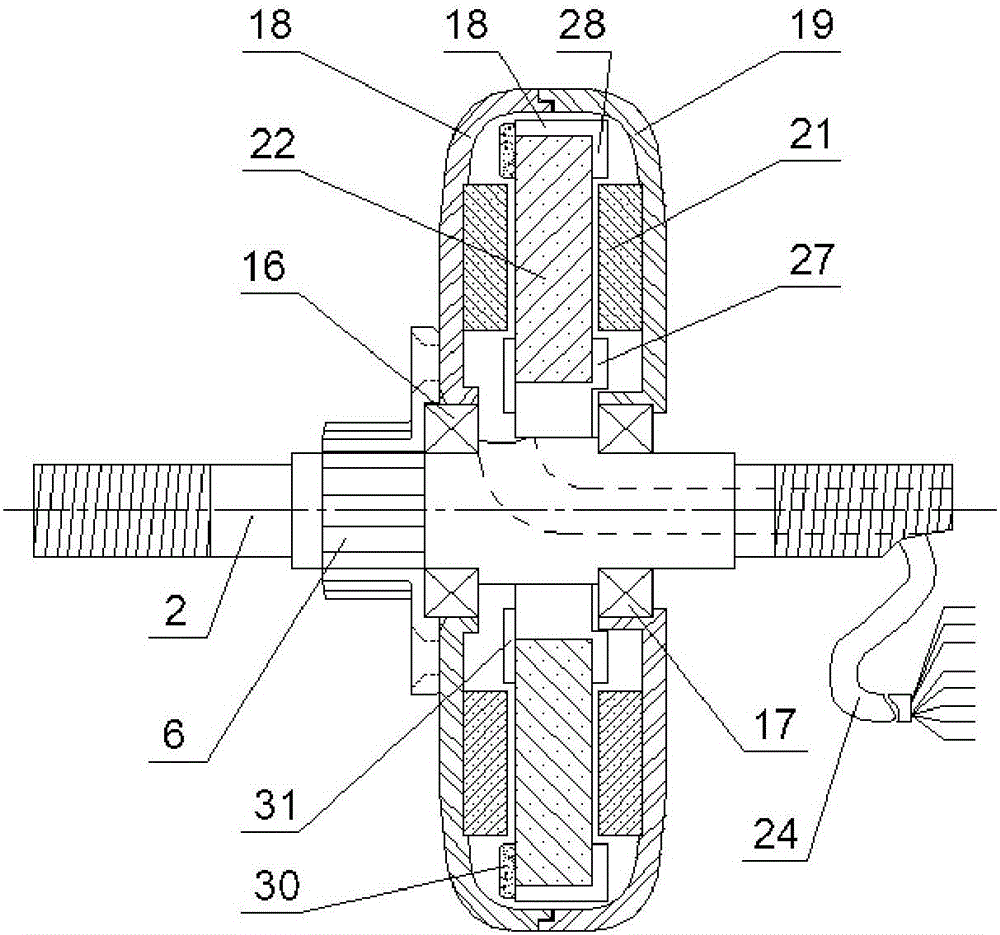

[0053] Disk-type unit laminated coreless DC motor, the winding on each stator disk is composed of 6 coils 22, the radial diameter of the coil 22 is D=32mm, the height is 10.0mm, the copper enameled wire diameter is 0.60mm, and the triangular hollow radial The length is 9.6mm, the average inner and outer diameters of the 8 permanent magnet units on each rotor disk are 68mm, the axial height is 6mm, and the radial length is 20mm. : 8.74 two-stage reduction of the planetary reduction mechanism, for comparative testing; Figure 13 Middle d is the curve diagram of torque and efficiency when the first power unit works alone, e is the curve diagram of torque and efficiency when the first power unit and the second power unit work simultaneously, Figure 13 It shows the torque efficiency curve diagram when the first power unit works and the first and second units work simultaneously in this embodiment of the disc-type unit laminated coreless DC motor of the present invention. From the ...

Embodiment 3

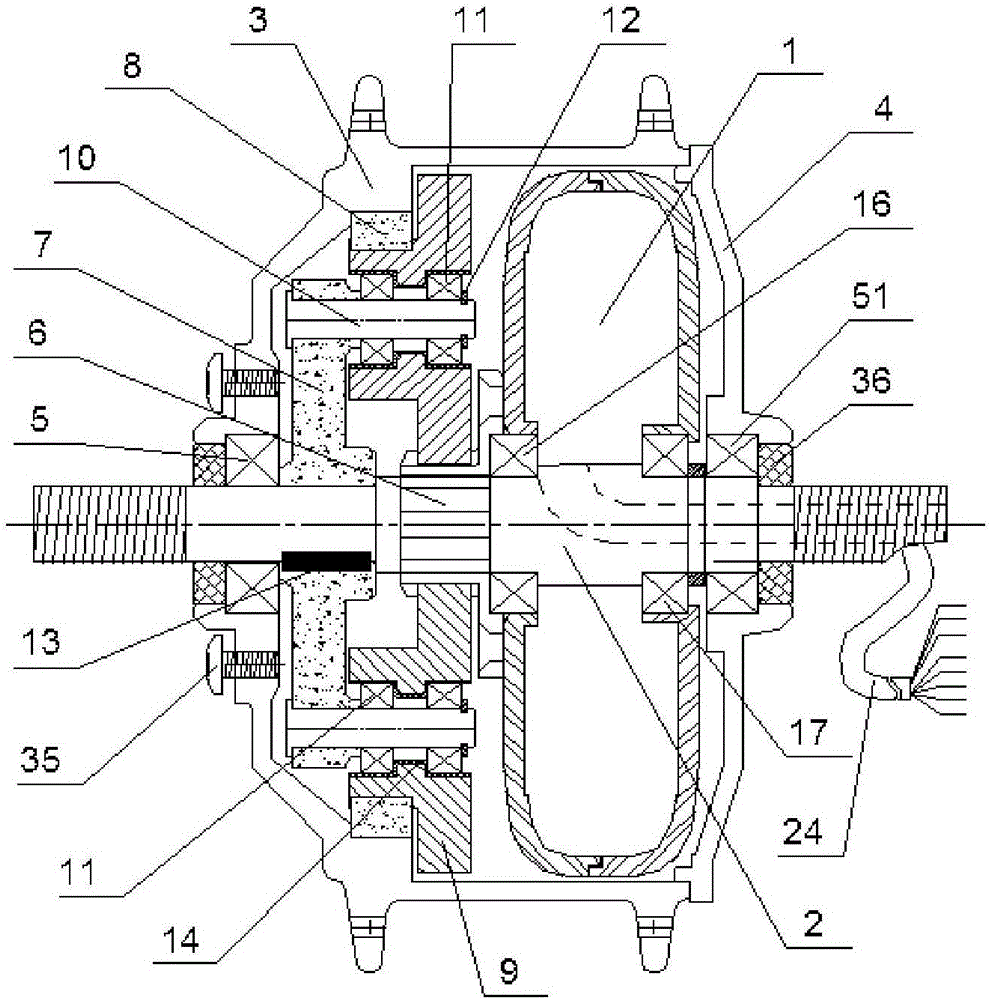

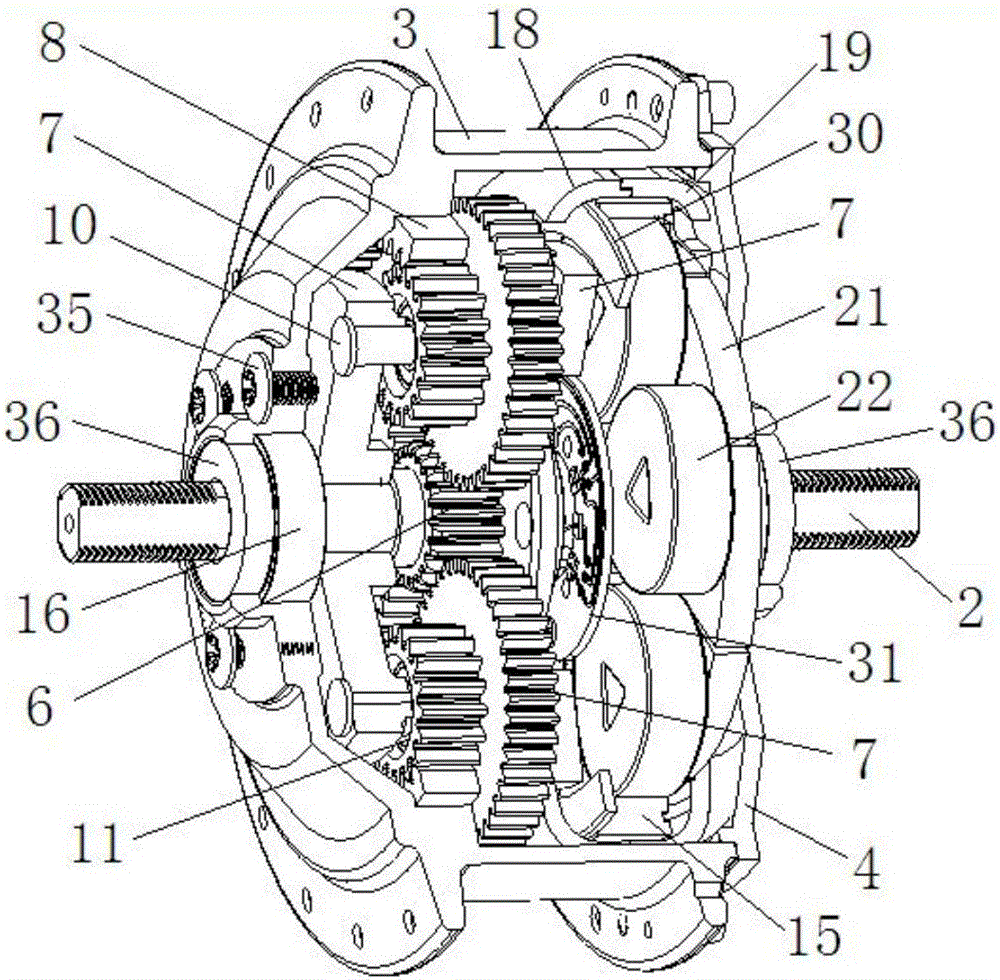

[0055] An energy-saving electric bicycle hub motor installed on a bicycle with a front wheel opening of 100mm. The pitch circle diameter of the spoke installation hole is 143mm, and the reduction ratio of the planetary gear mechanism is 1:7.9. The sun gear ring gear and the center wheel 8 is powder metallurgy material, double structure planetary gear 9 is die-casting molding of nylon material; drive motor adopts image 3 For the disc-type ironless DC motor shown, the motor input voltage is 48V, the no-load speed of the disc motor is 2780rpm, the no-load speed of the hub motor is 348rpm, and the best efficiency point power is 240W. The side of the hub 3 of the hub motor is provided with a butterfly brake mounting hole and a solid screw 35, and a waterproof sealing ring 36 is set on the outside of the first bearing 5 and the second bearing 51 on the main shaft 2, which improves the waterproof performance of the hub motor. Such as Figure 9 As shown, the center of the planet car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com