A preparation facility and preparation method for sun-cured red tobacco

A modulation method and a technology of drying red smoke, which are applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of cost, excessive loss, and many manpower, and achieve the effect of simple construction and easy promotion of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

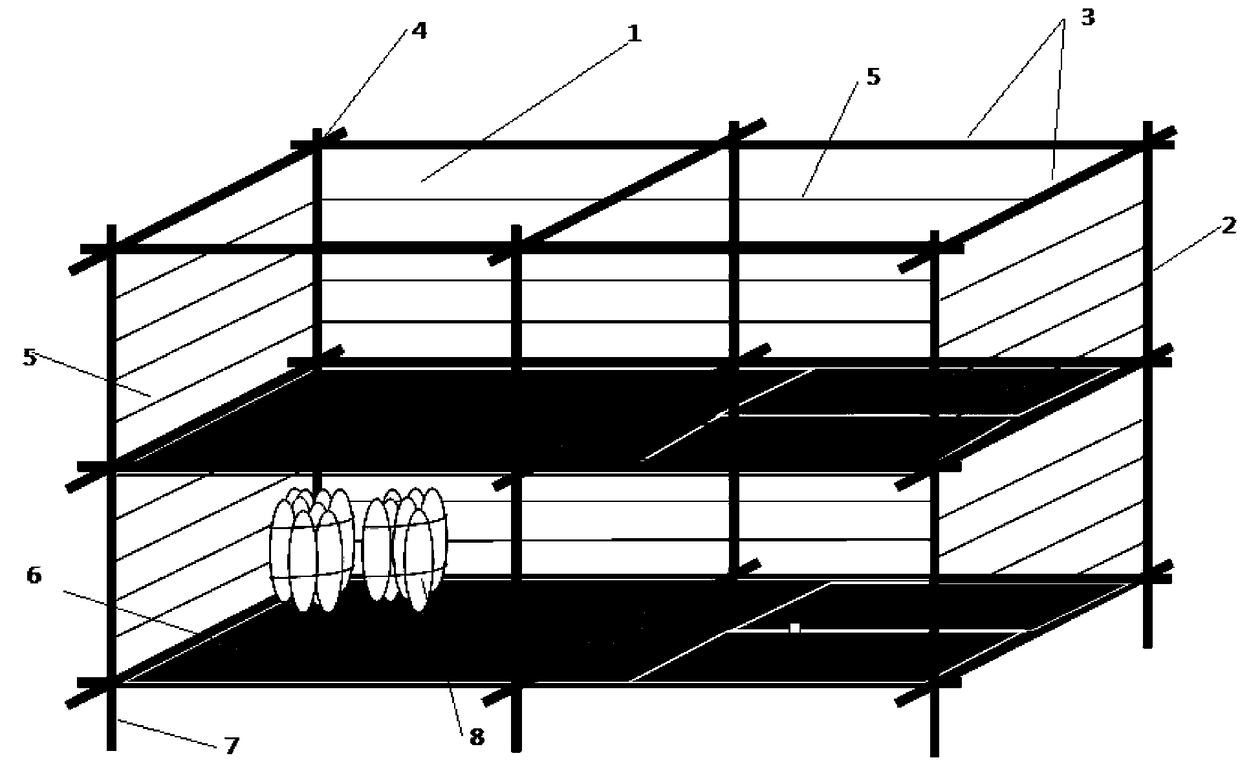

Image

Examples

Embodiment 1

[0050] Example 1 Comparison of the new modulation method of sun-dried red tobacco and the adjustment of tobacco leaves by traditional methods

[0051] 1 Test overview

[0052] Test location: Wutai Village, Gaozhuang Town, Yishui County, Shandong Province. Experimental variety: Yishui Shuzi. Test time: August 2, 2016.

[0053] 2 Experimental design

[0054] A treatment (the new modulation method of the present invention) and a control (the local traditional modulation method) were set in the experiment.

[0055] Treatment method: 1) Tobacco leaves are piled up and covered

[0056] Excavate cellars or caves in vacant land, the specifications are: length 8.0m, width 3.0m, height 2.5m; cellars or caves need to leave vents and be equipped with moisture drainage devices. In the cellar or cave, bamboo poles or wooden sticks are used to form a shelf, and three layers are made according to the length of the tobacco leaves. The mature tobacco leaves harvested from the field are bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com