Safe and efficient dedusting, cooling and fire extinguishing multifunctional system

A multi-functional and high-efficiency technology, applied in fire rescue, use of liquid separation agent, lighting and heating equipment, etc., can solve the problems of low dust suppression efficiency, large water consumption, pollution, etc., and achieve the effect of reducing labor intensity and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

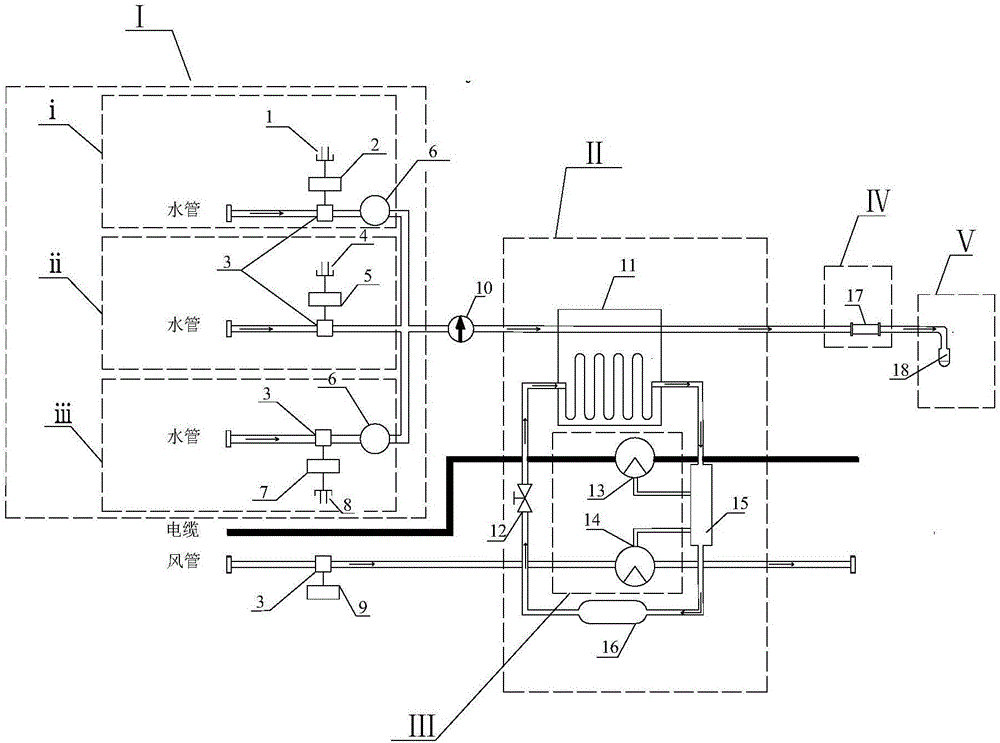

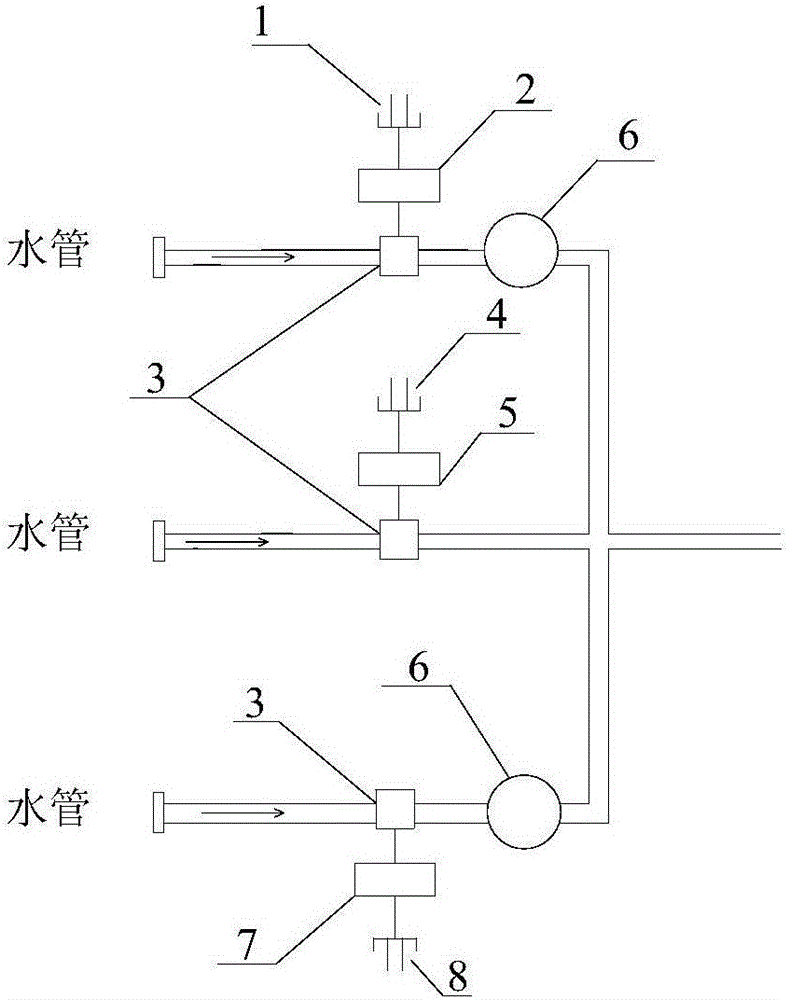

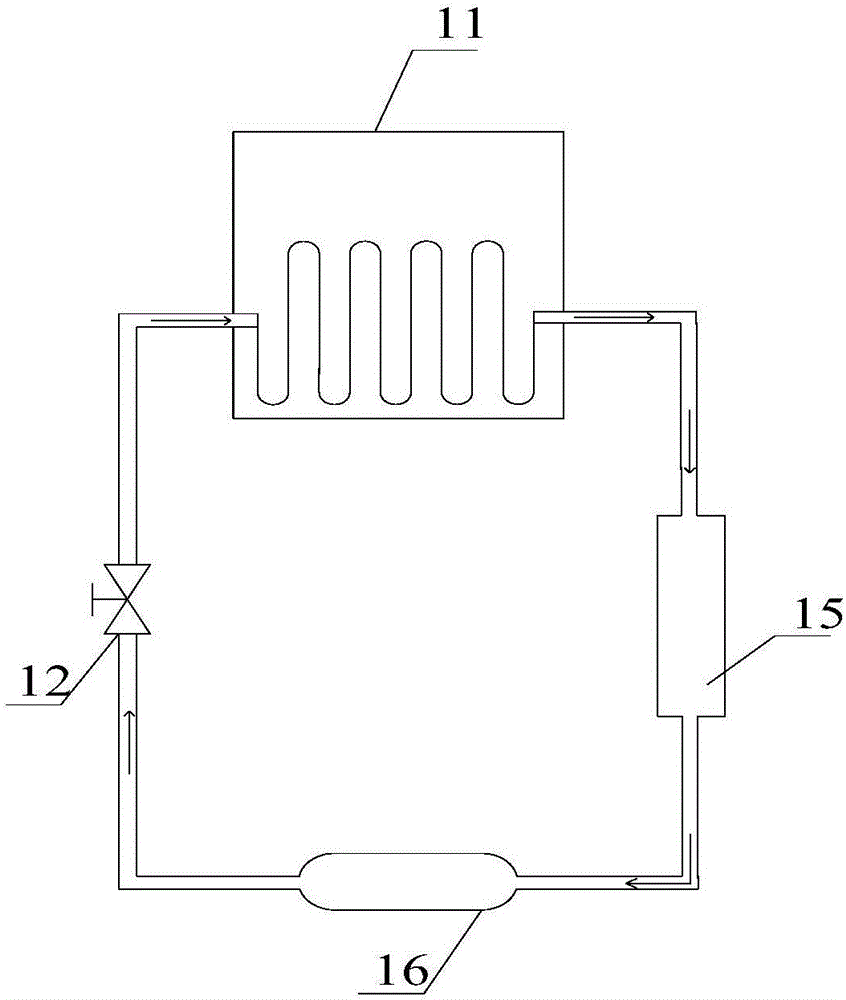

[0036] figure 1 The safe and efficient dust removal, temperature reduction and fire extinguishing multifunctional system shown is composed of induction unit Ⅰ, cooling unit Ⅱ, power unit Ⅲ, magnetization unit Ⅳ and spiral atomizing spherical nozzle Ⅴ. Air and water connecting pipelines and cable lines. The sensing unit I includes a dust concentration sensing part i, a temperature sensing part ii and a fire source sensing part iii. The solenoid valve 3 of the water inlet pipe is connected with the load cold water tank of the evaporator 11. The dust concentration sensing part i includes a dust concentration sensor 1, an automatic dust removal device controller 2, a solenoid valve 3, and a pure water hydraulic pump 6; the temperature sensing part ii includes a temperature sensor 4, an automatic cooling device controller 5, and a solenoid valve 3 ; The fire sensing part Ⅲ includes solenoid valve 3, automatic fire extinguishing equipment controller 7, infrared sensor 8, and pure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com