Flue gas dehumidification and white removal apparatus for wet desulfurization

A wet desulfurization and flue gas technology, applied in gas treatment, steam condensation, separation methods, etc., can solve the problems of flue gas reheater sulfate crystallization blockage, easy corrosion, etc., to achieve environmental protection, heat balance, reduce Effects of Pollutant Emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and examples.

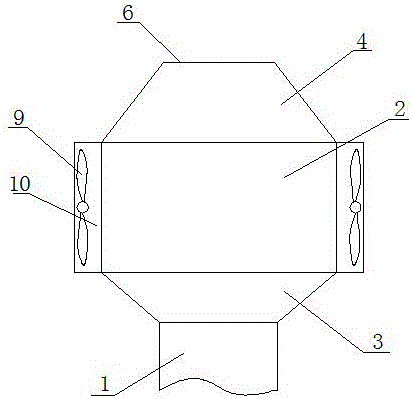

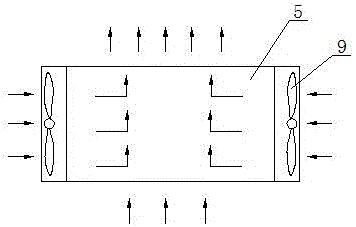

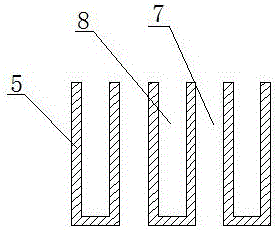

[0023] like figure 1 As shown, the flue gas dehumidification and whitening device of the present invention is mainly used for the treatment of flue gas after wet desulfurization, and it includes a flue gas treatment chamber 2 arranged on the upper part of the chimney 1 for discharging flue gas, and the flue gas treatment chamber 2 passes through an upper end The transitional buffer chamber 3 whose interface shape is adapted to its bottom is sealedly connected with the chimney 1 . The transitional buffer chamber 3 serves as an intermediate adapter to realize the connection between the flue gas treatment chamber 2 and the chimney 1 with different shapes. At the same time, the transition buffer chamber 3 also plays the role of buffering and dispersing the flue gas, and the flue gas is uniformly dispersed and then enters the flue gas t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com