A petal-shaped ammonia injection device for coke oven flue gas denitrification

A petal-shaped, denitrification technology, applied in the direction of gas treatment, separation methods, dispersed particle separation, etc., can solve the problems of flue gas temperature reduction, system resistance increase, etc., to reduce sensible heat loss, reduce heat loss, and simplify the structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

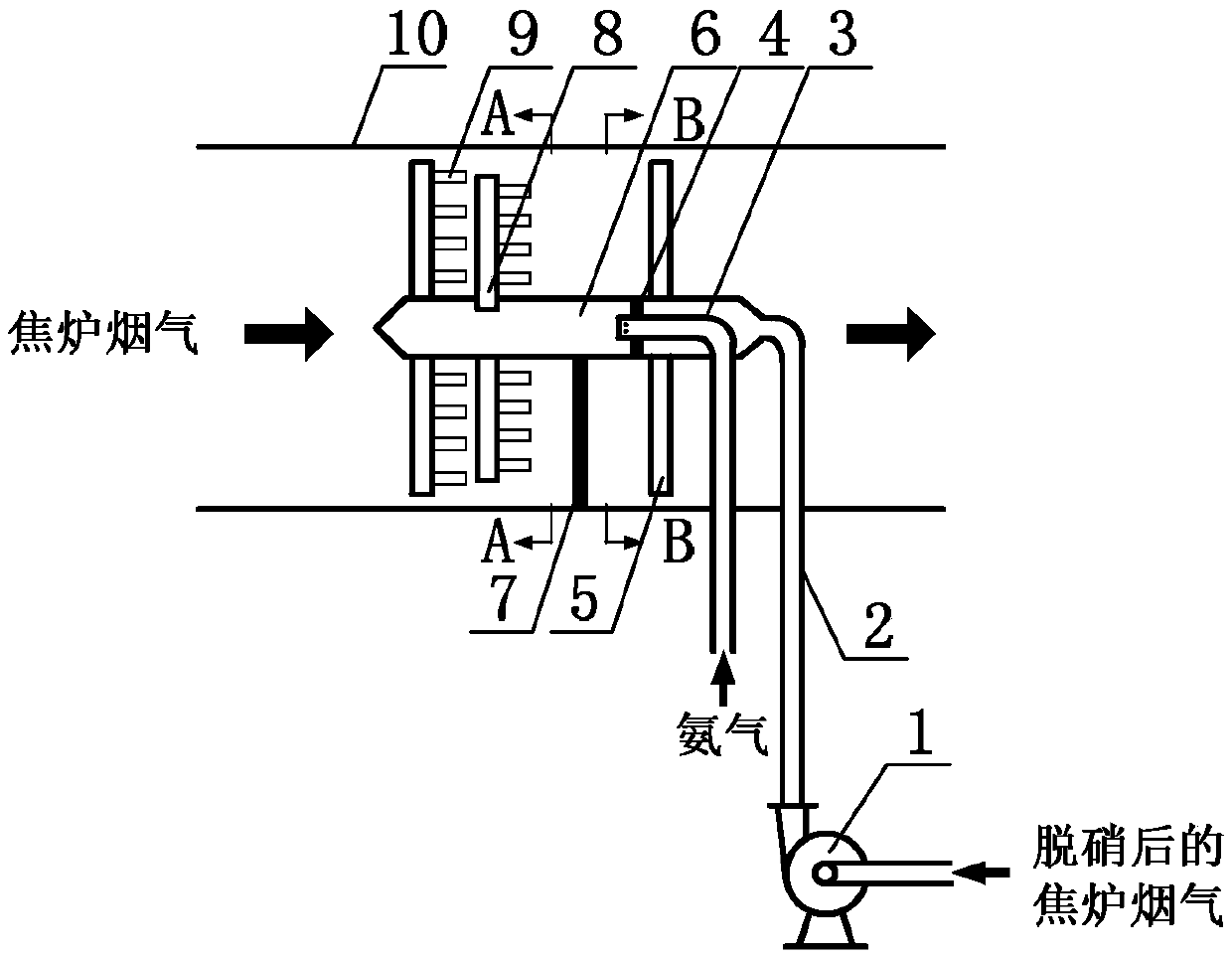

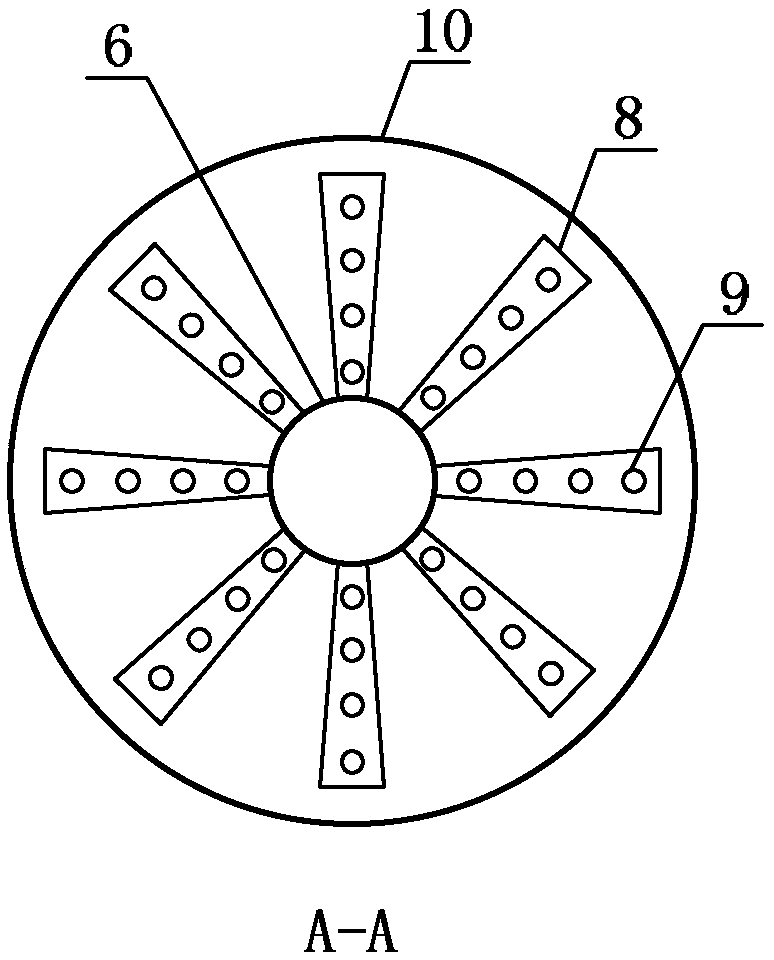

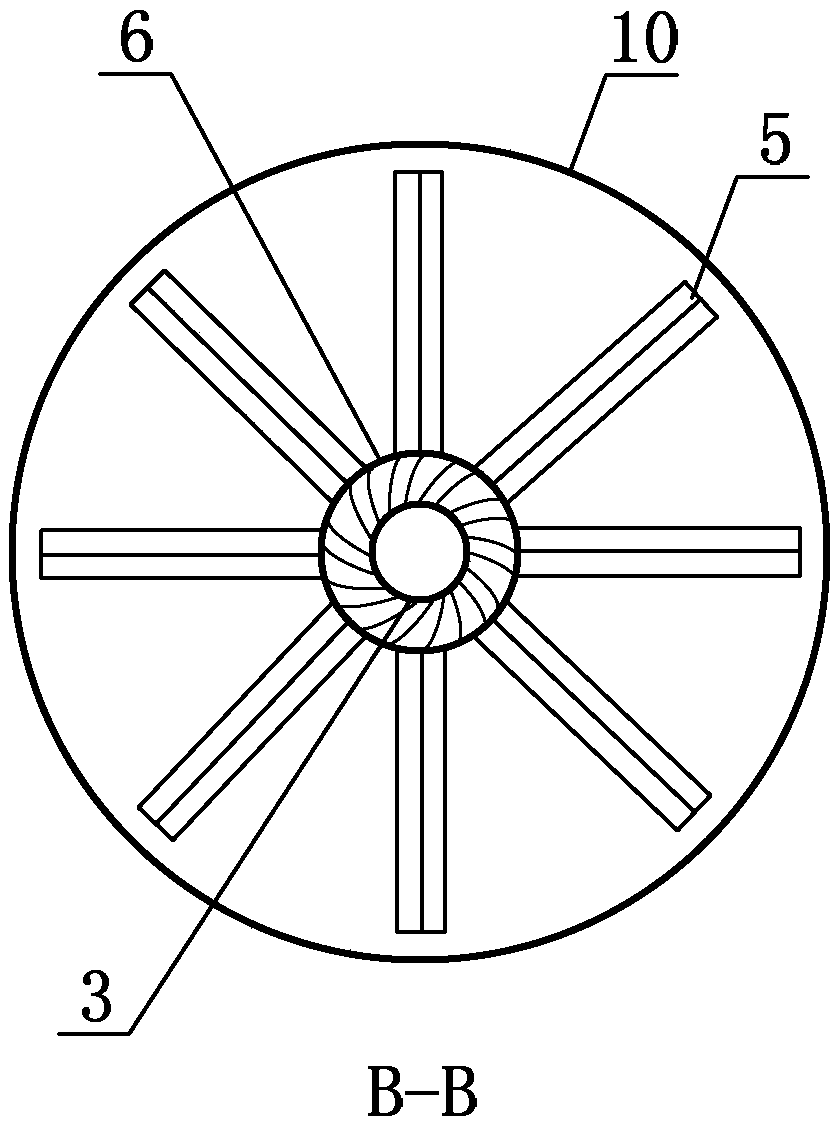

[0028] The invention provides a petal-shaped ammonia injection device for denitrification of coke oven flue gas. The petal-shaped ammonia injection device is arranged in a flue. pipes and secondary ammonia injection pipes, such as Figure 1~3 As shown, the mixer is a circular tube, which is installed horizontally in the flue. The coke oven flue gas inlet and the ammonia gas inlet are connected to the ammonia gas inlet pipe that enters the flue vertically. The coke oven flue gas inlet after denitration is connected to the flue gas inlet pipe that enters the flue vertically. After the flue is connected, the circulating fan sucks the denitrified coke oven flue gas to dilute the ammonia gas, the inlet end is connected to the denitrified coke oven flue gas, and the outlet end is connected to the flue gas inlet pipe connected to the mixer. The middle part of the mixer is supported by a tube support, one side of the tube support supports the mixer, and the other side is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com