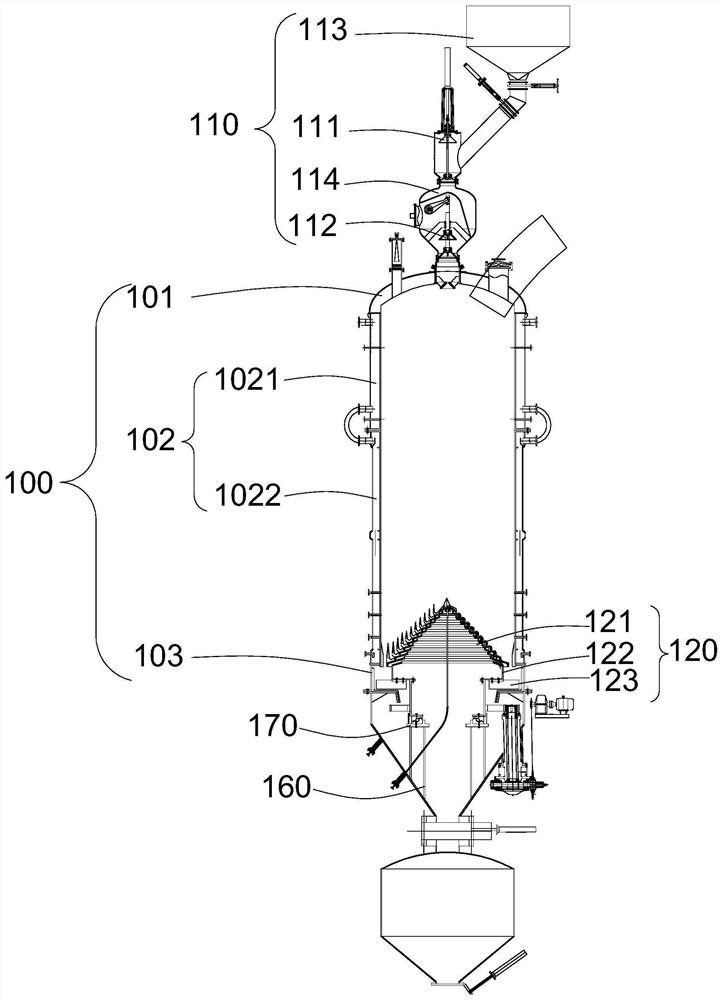

Fixed bed gasifier, production system and production method thereof

A fixed-bed gasifier and production system technology, applied in the field of gas manufacturing equipment, can solve the problems of easy to wear furnace and poor slag discharge, uneconomical operation, increase of co-solvent and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

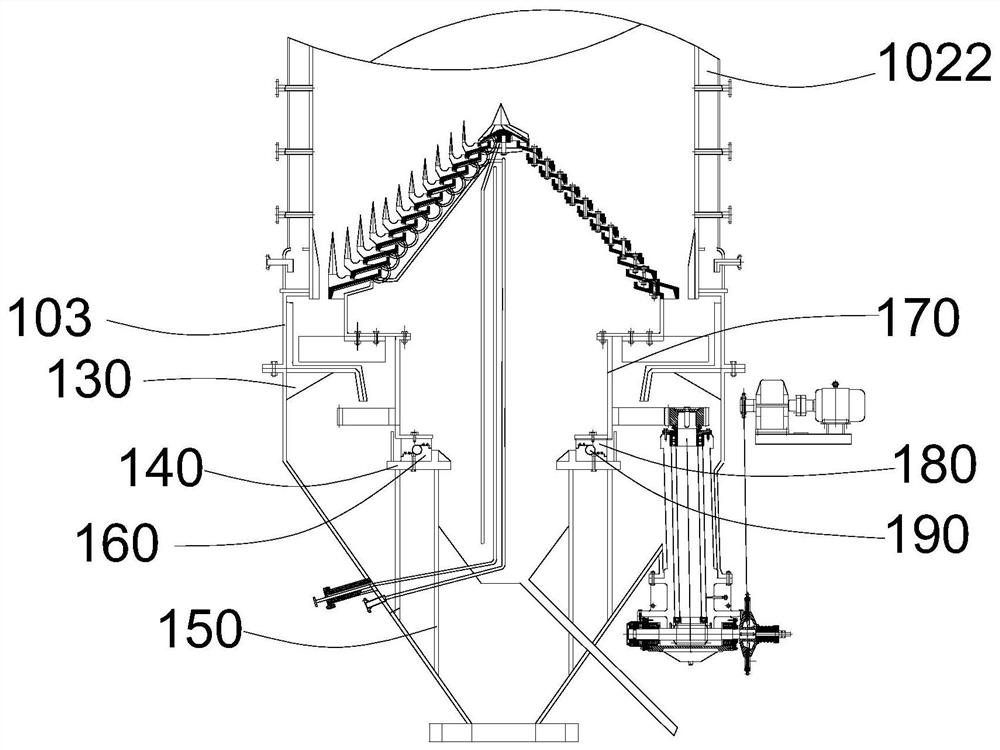

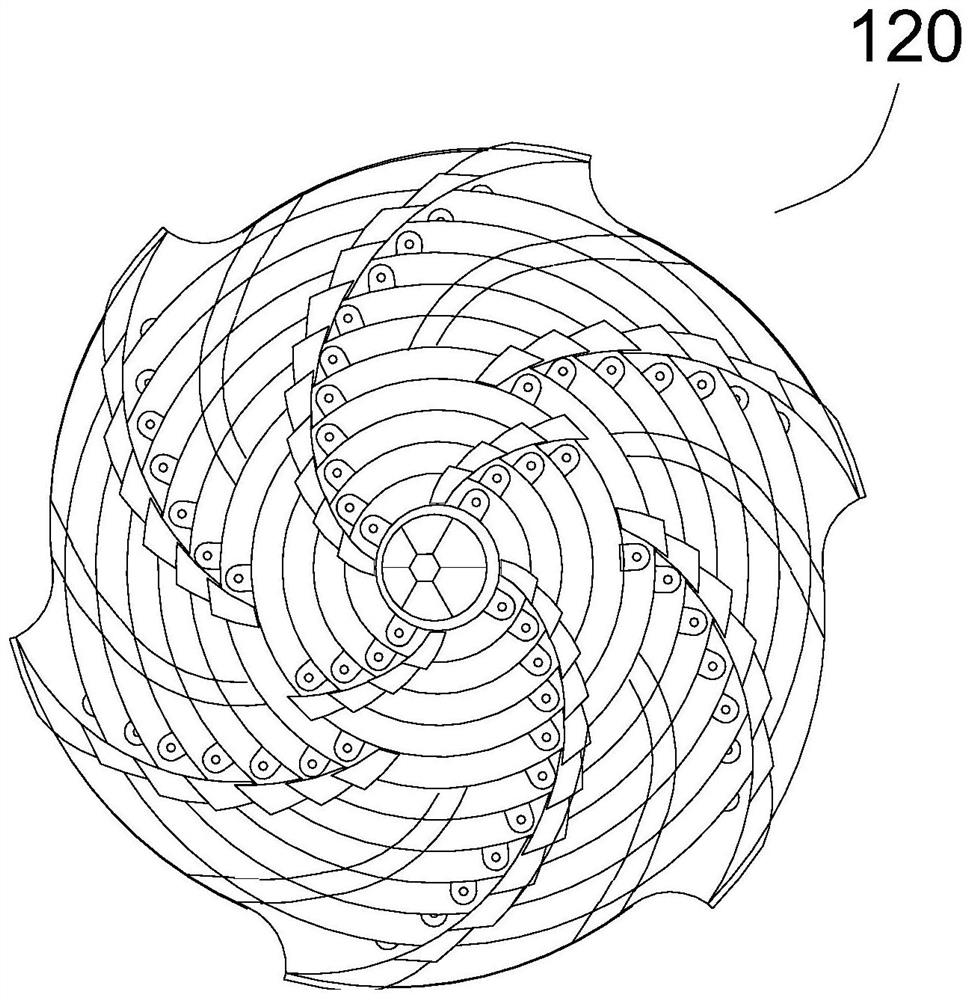

[0051] The theoretical basis of fixed bed gasification is that the uniformity of gasification in the radial direction of the material layer is the prerequisite for stable furnace conditions. The difference in material layer resistance in the radial direction of the furnace is determined by the particle size range and particle size to distribute the gasification agent. Since the particle size of the raw material cannot be consistent, a certain particle size range is required for entering the furnace. When the raw material enters the furnace from the feed port of the furnace body, according to the natural accumulation law of the raw material, the particle size will be separated naturally, and the larger the particle size range, the larger the particle size. The more obvious the degree of separation is, the large particle raw materials will fall on the edge of the grate, and the small particle raw materials will move to the center in turn under the support of the large particle ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com