A kind of formula of elastic grinding disc and its processing method

An elastic and abrasive technology, applied in metal processing, metal processing equipment, abrasives, etc., can solve the problems of low surface accuracy of the processed workpiece, decreased safety performance of elastic abrasives, and damage to the internal structure of elastic abrasives, etc., to achieve guarantee Uniformity of inside and outside organization, improvement of polishing feel and comfort, and improvement of polishing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

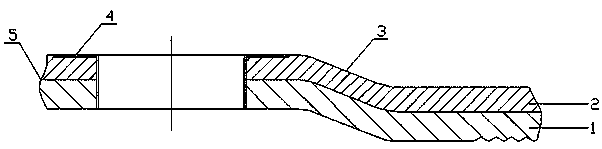

[0048] see figure 1 , in the embodiment of the present invention, a formula of an elastic abrasive disc, comprising a fine material layer 2 and a coarse material layer 1 compounded up and down,

[0049] The raw materials of the coarse material layer 1 are composed by weight: 60 parts of 80-mesh SG abrasive, 15 parts of 80-mesh high-temperature calcined brown corundum, 25 parts of 60-mesh white corundum, 2 parts of liquid phenolic resin, 0.5 part of liquid nitrile rubber, 26 parts of 325-mesh powdered phenolic resin, 1 part of 325-mesh decolorized and dewaxed shellac powder, 2 parts of 325-mesh diamond powder, 0.1 part of nano-scale fumed silica, 2 parts of 400-mesh magnesium oxide powder, 3 parts of 600-mesh titanium dioxide 1 part of 800 mesh phthalocyanine green;

[0050] Wherein, the viscosity of the liquid phenolic resin is 200mPa·s (25°C), the addition of the liquid nitrile rubber remains unchanged according to the liquid phenolic resin:liquid nitrile rubber=4:1, the SG ...

Embodiment 2

[0063] see figure 1 , in the embodiment of the present invention, a formula of an elastic abrasive disc, comprising a fine material layer 2 and a coarse material layer 1 compounded up and down,

[0064] The raw materials of the coarse material layer 1 are composed by weight: 50 parts of 80-mesh SG abrasive, 20 parts of 80-mesh high-temperature calcined brown corundum, 30 parts of 60-mesh white corundum, 4 parts of liquid phenolic resin, 1 part of liquid NBR, 23 parts of 325-mesh powdered phenolic resin, 2 parts of 325-mesh decolorized and dewaxed shellac powder, 5 parts of 400-mesh diamond powder, 0.5 parts of nano-scale fumed silica, 1 part of 500-mesh magnesium oxide powder, 1.5 parts of 800-mesh titanium dioxide , 0.6 parts of 800 mesh phthalocyanine green;

[0065] Wherein, the viscosity of the liquid phenolic resin is 350mPa·s (25°C), the addition of the liquid nitrile rubber remains unchanged according to the liquid phenolic resin:liquid nitrile rubber=4:1, the SG abras...

Embodiment 3

[0078] see figure 1 , in the embodiment of the present invention, a formula of an elastic abrasive disc, comprising a fine material layer 2 and a coarse material layer 1 compounded up and down,

[0079] The raw materials of the coarse material layer 1 are composed by weight: 40 parts of 80-mesh SG abrasive, 25 parts of 80-mesh high-temperature calcined brown corundum, 35 parts of 60-mesh white corundum, 6 parts of liquid phenolic resin, 1.5 parts of liquid NBR, 18 parts of 400-mesh powdered phenolic resin, 3 parts of 400-mesh decolorized and dewaxed shellac powder, 8 parts of 400-mesh diamond powder, 1 part of nano-scale fumed silica, 0.5 part of 600-mesh magnesium oxide powder, 0.5 part of 800-mesh titanium dioxide , 0.2 part of 1000 mesh phthalocyanine green;

[0080] Wherein, the viscosity of the liquid phenolic resin is 500mPa·s (25°C), the addition of the liquid nitrile rubber remains unchanged according to the liquid phenolic resin:liquid nitrile rubber=4:1, the SG abra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com