Production device and method for delamination and fiber forming of bamboo

A production device and production method technology, applied in the direction of manufacturing tools, wood processing appliances, mechanical equipment, etc., can solve the problems that can only be used in the application field of fiberboard or low-grade composite materials, the qualified rate and fiber extraction rate of bamboo fiber are low, and the impact The problems of obtaining bamboo rough fiber, etc., achieve the effect of easy operation and promotion, good uniformity, and saving production time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

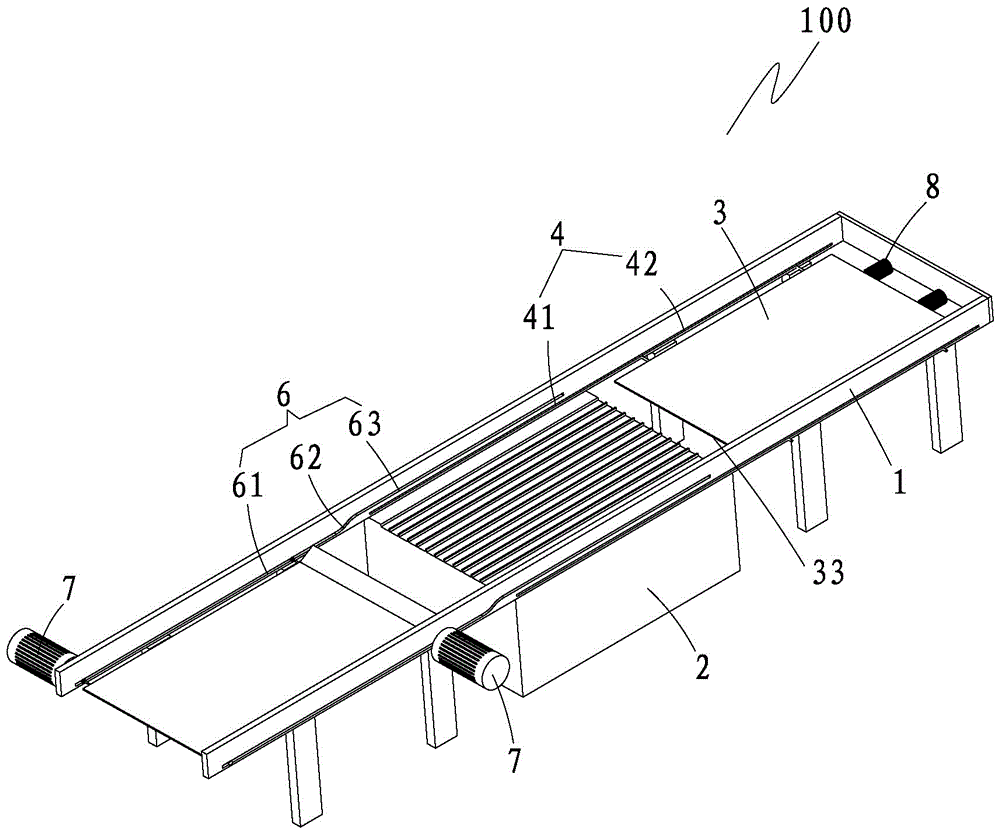

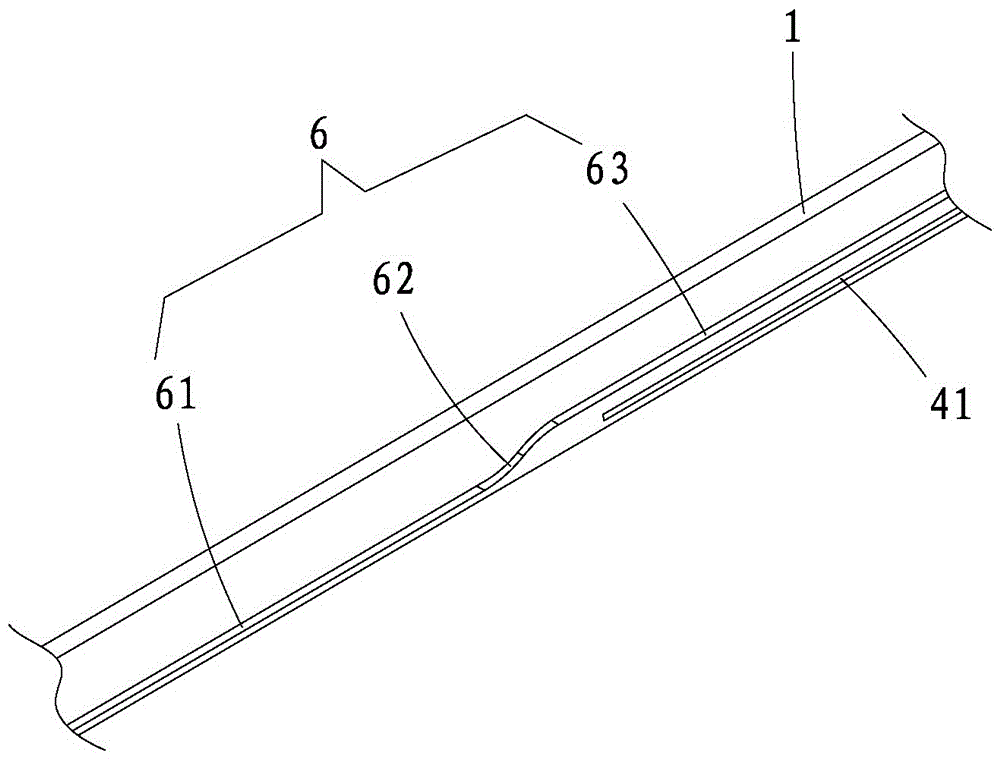

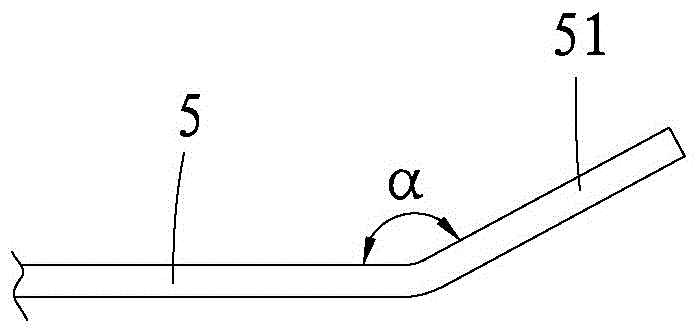

[0036] Please combine Figure 1 to Figure 7 , a kind of manufacturing device 100 of bamboo material delamination into fiber of the present invention, comprises a frame 1, a machine tool seat 2, a machine tool cover 3 matched with the machine tool seat 2, a machine tool cover track 4, a push plate 5, A push track 6, at least one power source 7 for sliding the push plate 5, and at least one elastic member 8; in this embodiment, the elastic member 8 adopts a compression spring, and one end of the compression spring is connected to the frame 1 On the right end, the other end of the compression spring is engaged on the right end of the implement cover 3 .

[0037] The machine tool base 2 is located in the middle of the frame 1, and the top of the machine tool base 2 is provided with a plurality of parallel grooves 21 and a first heating group 22, the first heating group 22 is embedded in the machine tool base 2 and is located in the recess. The groove 21 below the groove 21 is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com