Preparation method of cesium doped tungsten oxide nano powder serving as infrared barrier

An infrared blocking and nano-powder technology, applied in the direction of tungsten oxide/tungsten hydroxide, nanotechnology, etc., can solve the problems of environmental harm, poor stability and high cost, and achieve the effects of good environmental protection, good stability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

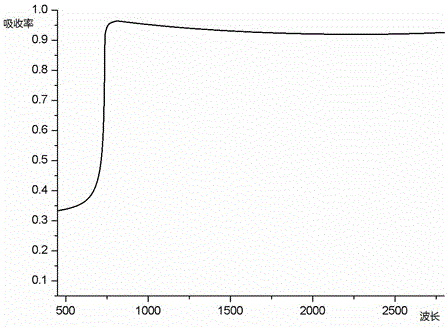

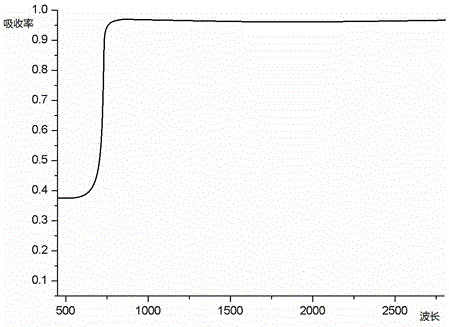

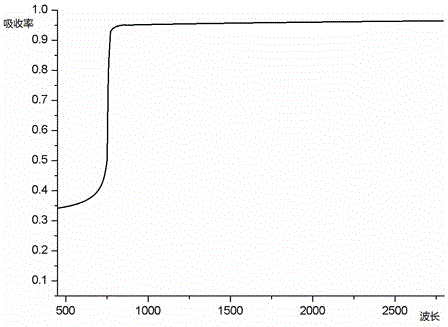

Image

Examples

preparation example Construction

[0023] A method for preparing cesium-doped tungsten oxide nanopowder as an infrared barrier, comprising the following steps:

[0024] (1) Dissolve the raw material tungsten salt and cesium salt of the reaction amount in the solvent respectively, and the tungsten salt solution is configured into a tungstic acid solution through the exchange resin;

[0025] (2) Mix tungstic acid solution, cesium salt solution, and reaction solvent, and keep stirring for 1 to 3 hours to obtain a hydrothermal reaction precursor;

[0026] (3) Put the precursor solution in a closed hydrothermal reaction kettle with a stirring device, and stir for 5-20 hours at 180-300°C;

[0027] (4) The hydrothermal reaction precipitate is repeatedly washed, dried, pulverized, and calcined to obtain the target product.

[0028] In step (1), the tungsten salt is any one of sodium tungstate, ammonium tungstate, and potassium tungstate, the cesium salt is any one of cesium carbonate, cesium nitrate, and cesium sulfat...

Embodiment 1

[0030] A method for preparing cesium-doped tungsten oxide nanopowder as an infrared barrier, comprising the following steps:

[0031] (1) Dissolve the raw materials sodium tungstate and cesium carbonate in deionized water respectively, and the sodium tungstate solution is configured into a tungstic acid solution through an exchange resin;

[0032] (2) Dissolve sorbic acid in deionized water to prepare a reaction solvent. The mass of the reaction solvent is 1.5 times the sum of the mass of tungsten salt and cesium salt. Mix tungstic acid solution, cesium carbonate solution, and reaction solvent for 60 Stirring for 2 hours in a water bath at ℃ to prepare a hydrothermal reaction precursor;

[0033] (3) Place the precursor solution in a closed hydrothermal reaction kettle with a stirring device, and stir for 12 hours at 200°C;

[0034] (4) After washing the hydrothermal reaction precipitate repeatedly with deionized water, dry it at 90°C for 10 hours, and then use a jet mill to g...

Embodiment 2

[0037] A method for preparing cesium-doped tungsten oxide nanopowder as an infrared barrier, comprising the following steps:

[0038] (1) Dissolve the raw materials ammonium tungstate and cesium nitrate of the reaction amount in absolute ethanol respectively, and the ammonium tungstate solution is configured into a tungstic acid solution through an exchange resin;

[0039] (2) Dissolve citric acid in absolute ethanol to prepare a reaction solvent. The mass of the reaction solvent is twice the sum of the mass of tungsten salt and cesium salt. Mix tungstic acid solution, cesium nitrate solution, and reaction solvent for continuous Stir in a water bath at 50°C for 1.5 hours to prepare a hydrothermal reaction precursor;

[0040] (3) Put the precursor solution in a closed hydrothermal reaction kettle with a stirring device, and stir for 12 hours at 180°C;

[0041] (4) After washing the hydrothermal reaction precipitate repeatedly with deionized water, dry it at 80°C for 8 hours, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com