Wastewater recovery treatment process for paper mill

A technology of wastewater recovery and treatment process, applied in the process of wastewater treatment, water/sewage treatment, biological water/sewage treatment, etc., can solve the problems of low treatment efficiency, environmental pollution, confusion of treatment steps, etc. The effect of reducing production costs and reducing waste water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

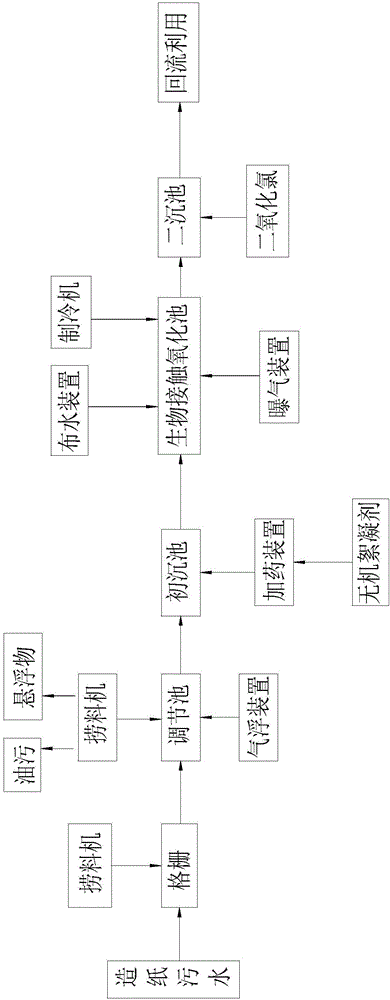

[0016] like figure 1 Shown, a kind of paper mill wastewater recovery treatment process comprises the following steps:

[0017] 1) Intercept a large amount of fibers, fiber fines and plant debris through the grille, and pick up the fibers, fiber fines and plant debris through the scooping machine to keep the grid flowing smoothly, and intercept the fibers, fiber In the sewage drainage adjustment tank after fine materials and plant debris;

[0018] 2) The sewage introduced into the adjustment tank is sprayed with a large number of micro-bubbles through the air flotation device, so that the suspended solids in the sewage can be concentrated for preliminary treatment, and at the same time, the oil in the sewage can float on the surface of the sewage under the action of the micro-bubbles , and then the oil on the surface of the sewage is scooped up by a fishing machine, the sewage treated with oil is drained into the primary sedimentation tank, and 120 parts of inorganic flocculan...

Embodiment 2

[0026] like figure 1 Shown, a kind of paper mill wastewater recovery treatment process comprises the following steps:

[0027] 1) Intercept a large amount of fibers, fiber fines and plant debris through the grille, and pick up the fibers, fiber fines and plant debris through the scooping machine to keep the grid flowing smoothly, and intercept the fibers, fiber In the sewage drainage adjustment tank after fine materials and plant debris;

[0028] 2) The sewage introduced into the adjustment tank is sprayed with a large number of micro-bubbles through the air flotation device, so that the suspended solids in the sewage can be concentrated for preliminary treatment, and at the same time, the oil in the sewage can float on the surface of the sewage under the action of the micro-bubbles , and then the oil on the surface of the sewage is scooped up by a fishing machine, the sewage treated with oil is drained into the primary sedimentation tank, and 150 parts of inorganic flocculan...

Embodiment 3

[0036] like figure 1 Shown, a kind of paper mill wastewater recovery treatment process comprises the following steps:

[0037] 1) Intercept a large amount of fibers, fiber fines and plant debris through the grille, and pick up the fibers, fiber fines and plant debris through the scooping machine to keep the grid flowing smoothly, and intercept the fibers, fiber In the sewage drainage adjustment tank after fine materials and plant debris;

[0038] 2) The sewage introduced into the adjustment tank is sprayed with a large number of micro-bubbles through the air flotation device, so that the suspended solids in the sewage can be concentrated for preliminary treatment, and at the same time, the oil in the sewage can float on the surface of the sewage under the action of the micro-bubbles , and then the oil on the surface of the sewage is scooped up by a fishing machine, and the oily sewage is drained into the primary sedimentation tank, and 180 parts of inorganic flocculants are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com