Ceramic tile with mineral crystal fancy glaze layer and preparation method thereof

A technology of mineral crystals and ceramic tiles, which is applied in the field of architectural ceramics production, can solve the problems of inability to simulate natural stone texture effects, monotonous decoration effects, and inability to simulate natural stone mineral crystal texture decoration effects, etc., to achieve rich nested texture effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

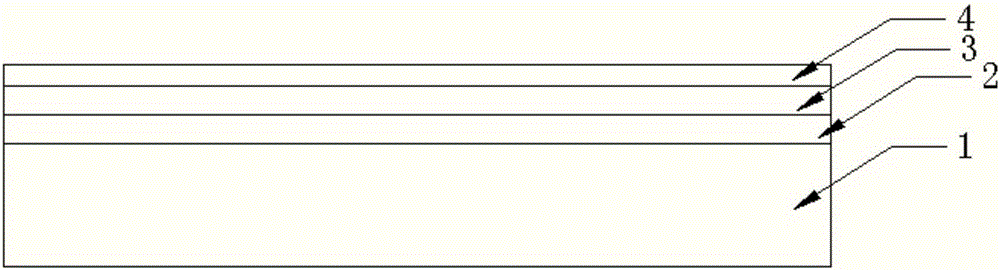

[0033] Refer to attached figure 1 , the present embodiment provides a ceramic tile with a whitening layer, which comprises from bottom to top: a green body layer 1, a glaze layer 2, a whitening layer 3 and a printed pattern layer 4, and the whitening layer 3 is made by screen printing Formed by whitening glaze, the thickness of the whitening layer 3 is 0.2-1.2mm.

[0034] Its preparation method is as follows:

[0035] Step 1) Selecting known ceramic body powder to be stamped into brick adobe;

[0036] Step 2) applying a known top glaze on the surface of the green body by glazing to form a top glaze layer;

[0037] Step 3) Printing a whitening glaze on the surface glaze layer by screen printing to form a whitening layer;

[0038] Step 4) adopting known printing methods to form a printing layer on the whitening layer;

[0039] Step 5) go into kiln and burn;

[0040] Step 6) Polishing and edging the fired body to obtain a ceramic tile product.

[0041] Wherein, the green bo...

Embodiment 2

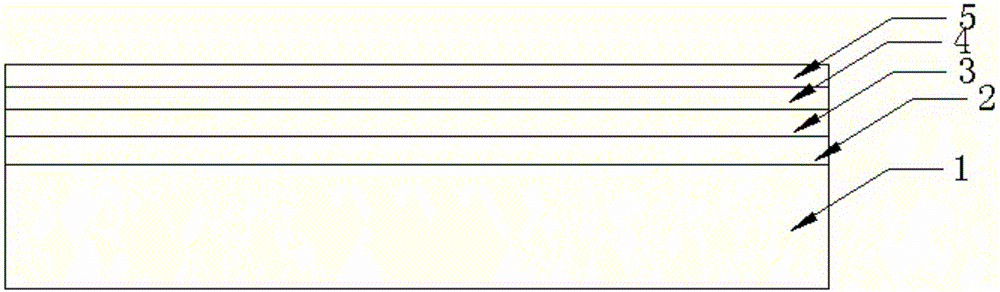

[0048] Refer to attached figure 2 , a kind of ceramic tile, it comprises from bottom to top: green body layer 1, surface glaze layer 2, whitening layer 3, printing pattern layer 4 and powdery glaze layer 5.

[0049] Here, the powder-enhancing glaze forming the powder-enhancing glaze layer 5 is calculated in parts by mass, and includes the following components: high-boron calcium transparent frit: 12 parts, 0.1-10 parts of complementary color pigments, carboxymethyl cellulose: 1.3 parts , ethylene glycol: 45 parts, water: 40 parts;

[0050] The chemical composition of the high boron calcium transparent frit is calculated in parts by weight of oxides, including the following components: Na 2 O: 6 parts, CaO: 12 parts, ZnO: 7 parts, B 2 o 3 : 8 servings, Al 2 o 3 :3 parts, SiO 2 :54 copies;

[0051] The complementary color pigment is one or more combinations of known ceramic glaze pigments.

[0052] For the preparation method, on the basis of Example 1, the step of apply...

Embodiment 3

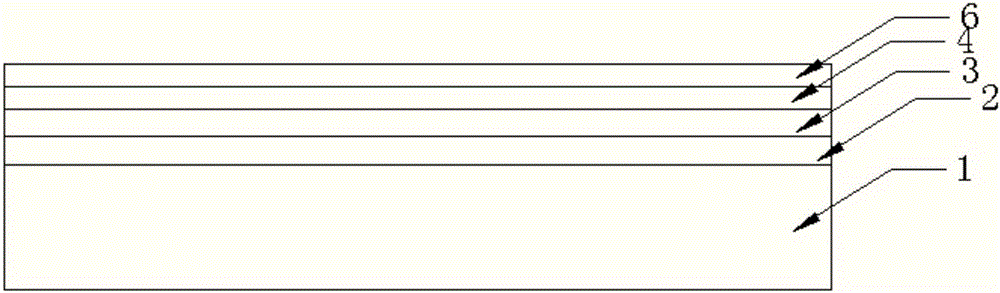

[0056] Refer to attached image 3 , a ceramic tile, which comprises from bottom to top: a body layer 1, a glaze layer 2, a whitening layer 3, a printed pattern layer 4 and a color-helping glaze layer 6.

[0057] Here, the color-helping glaze forming the color-helping glaze layer 6 is calculated in parts by mass, and includes the following components: 100 parts of high-zinc frit, 130 parts of printing paste, 0.3 parts of sodium tripolyphosphate, and 40 parts of water share;

[0058] The chemical components of the high-zinc frit are calculated in parts by weight of oxides, and include the following components:

[0059] SiO 2 : 53 parts, ZnO: 21 parts, K 2 O: 4 parts, Al 2 o 3 : 7 parts, MgO: 3 parts, CaO: 3.5 parts.

[0060] It should be noted that the inner glaze layer 2 and the whitening layer 3 may not be applied here, and of course the effect of the obtained ceramic tile product will decrease correspondingly. Of course, it is also possible to also include the powder-e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com