Preparation method of sound-absorbing rubber

A technology of rubber and nitrile rubber, which is applied in the field of rubber, can solve problems such as restricting automobile noise and noise control, and achieve good mechanical properties, high chemical stability, and good aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

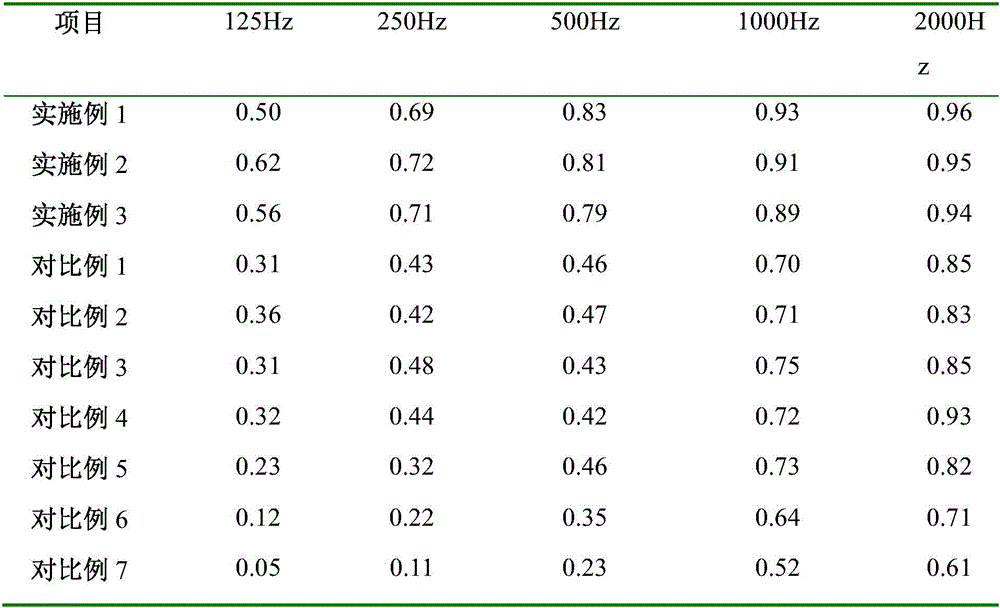

Examples

preparation example Construction

[0014] The invention provides a method for preparing sound-absorbing rubber, which is characterized in that the method comprises: 100-150 parts by weight of nitrile rubber, 5-15 parts by weight of hollow glass microspheres, and 3-8 parts by weight of nanometer disulfide Molybdenum, 1-6 parts by weight of lanthanum oxide, 3-15 parts by weight of azodicarbonamide, 1-5 parts by weight of urea, 2-8 parts by weight of carbon nanotubes and 5-15 parts by weight of ternary ethyl The formula of propylene rubber puts the raw material of sound-absorbing rubber into an open mixer for mixing, and the mixed product is placed for 12-48 hours before re-milling, and the re-milled product is sent to a flat vulcanizing machine for pressure vulcanization and vulcanization in sequence. Pressure setting; preferably, the sound-absorbing rubber includes 120-140 parts by weight of nitrile rubber, 8-12 parts by weight of hollow glass microspheres, 4-6 parts by weight of nano molybdenum disulfide, 2-4 pa...

Embodiment 1

[0020] With the nitrile rubber of 100 parts by weight, the hollow glass microsphere of 5 parts by weight of 50 nanometers, the 2-thiol benzothiazole of 3 parts by weight, the lanthanum oxide of 1 part by weight, the azodicarbonamide of 3 parts by weight, 1 part by weight of urea, 2 parts by weight of carbon nanotubes and 5 parts by weight of EPDM rubber were placed in an open mill at 150°C for 3 minutes, and the product obtained by mixing was placed at 150°C for 12 hours. Re-smelting at 150° C. for 5 seconds at 5 MPa and 150° C. for pressure vulcanization on a flat vulcanizing machine. After depressurization to normal pressure, stabilize at 150° C. for 45 seconds to obtain Sound-absorbing rubber CL-1.

Embodiment 2

[0022] The nitrile rubber of 120 parts by weight, the hollow glass microspheres of 10 parts by weight of 200 nanometers, the dithiuram tetrasulfide of 5 parts by weight, the lanthanum oxide of 4 parts by weight, the azodicarbonamide of 8 parts by weight, the azodicarbonamide of 3 parts by weight 5 parts by weight of urea, 5 parts by weight of carbon nanotubes and 10 parts by weight of EPDM rubber were put into an open mill at 170°C and mixed for 10 minutes, and the product obtained by mixing was placed at 190°C for 24 hours. Remelting for 8 minutes, put the product obtained from the remilling into a flat vulcanizing machine, vulcanize under pressure at 10 MPa at 190°C for 20 seconds, release the pressure to normal pressure and stabilize at 190°C for 80 seconds to obtain sound-absorbing rubber CL-2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com