Polyacrylate pressure-sensitive adhesive and preparation method thereof

A polyacrylate and pressure-sensitive adhesive technology, applied in the field of pressure-sensitive adhesives, can solve the problems of difficulty in air permeability, molecular chain entanglement, and difficulty in waterproofing, and achieve the effects of excellent air permeability and waterproof performance, simple preparation process and excellent waterproof performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

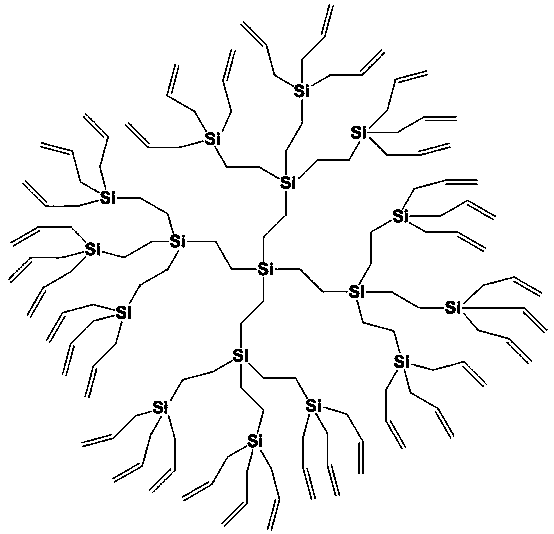

Image

Examples

Embodiment 1

[0029] Weigh 35g of deionized water and 1g of emulsifier SC-09 into the pre-emulsification kettle, turn on the stirring device, add 0.02g of hyperbranched polysilane, 99.98g of methyl methacrylate, and stir for 30 minutes. Add 50g of deionized water and 1g of emulsifier SC-09 into the reaction kettle, turn on the condensation reflux device, stir and raise the temperature to 80°C, dissolve 0.8g of initiator ammonium persulfate in 20g of water, add it to the reaction kettle at one time, and raise the temperature to 83 ℃, add 17g of core structure pre-emulsion, and react for 30 minutes. Dissolve 1 g of the initiator ammonium persulfate in 45 g of water, drop it into the reaction kettle simultaneously with the remaining core structure pre-emulsion, drop it for 3 hours, and keep it warm for 30 minutes.

[0030] Weigh 60g isooctyl acrylate, 40g butyl acrylate, weigh 1g emulsifier SC-09 and mix with isooctyl acrylate and butyl acrylate; weigh 1g initiator ammonium persulfate and diss...

Embodiment 2

[0033] Weigh 33g of deionized water and 1g of emulsifier SC-09 into the pre-emulsification tank, turn on the stirring device, add 0.06g of hyperbranched polysilane, 99.94g of methyl methacrylate, and stir for 30 minutes. Add 50g of deionized water and 1g of emulsifier SC-09 into the reaction kettle, turn on the condensation reflux device, stir and raise the temperature to 80°C, dissolve 0.8g of initiator ammonium persulfate in 20g of water, add it to the reaction kettle at one time, and raise the temperature to 83 ℃. Dissolve 1 g of the initiator ammonium persulfate in 47 g of water, drop it into the reaction kettle simultaneously with the core structure pre-emulsion, drop it for 3 hours, and keep it warm for 30 minutes.

[0034] Weigh 50g isooctyl acrylate, 50g butyl acrylate, weigh 1g emulsifier SC-09 and mix with isooctyl acrylate and butyl acrylate; weigh 1g initiator ammonium persulfate and dissolve in 50g water; weigh the above The substance was added dropwise in the re...

Embodiment 3

[0037] Weigh 38g of deionized water and 1g of emulsifier CO-436 into the pre-emulsification tank, turn on the stirring device, add 0.1g of hyperbranched polysilane, 99.9g of styrene, and stir for 30 minutes. Add 40g of deionized water and 1g of emulsifier CO-436 into the reaction kettle, turn on the condensation reflux device, stir and raise the temperature to 80°C, dissolve 0.8g of initiator ammonium persulfate in 12g of water, add it to the reaction kettle at one time, and raise the temperature to 82 ℃, add 20 g of core structure pre-emulsion, and react for 30 minutes. Dissolve 1 g of the initiator ammonium persulfate in 55 g of water, drop it into the reaction kettle simultaneously with the remaining core structure pre-emulsion, drop it for 3 hours, and keep it warm for 30 minutes.

[0038] Weigh 60g isooctyl acrylate, 40g butyl acrylate, weigh 1g emulsifier CO-436 and mix with isooctyl acrylate and butyl acrylate; weigh 1g initiator ammonium persulfate and dissolve in 55g ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Branching factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com