A kind of method for preparing amoxicillin by deesterification liquid

A technology of amoxicillin and deesterification solution, which is applied in the field of preparing amoxicillin from deesterification solution and preparing amoxicillin and phenylacetic acid, which can solve the impact of amoxicillin product quality, unfavorable amoxicillin synthesis yield, 6 -The problem of low APA concentration, to achieve the effect of less colored impurities, good product quality and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

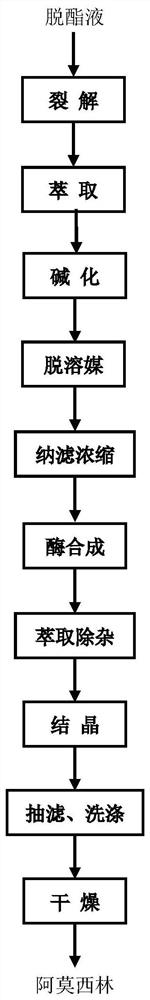

Method used

Image

Examples

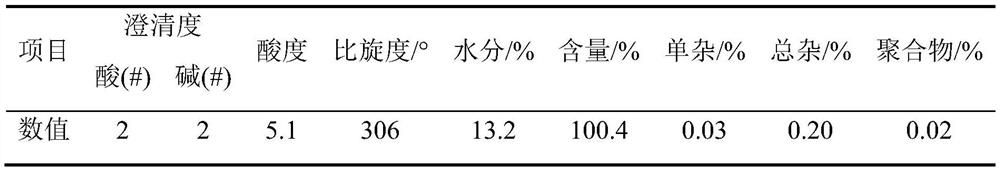

Embodiment 1

[0035] Embodiment 1 The method for preparing amoxicillin by deesterification solution according to the present invention

[0036] (1) Deesterification solution cracking

[0037] Take 200L deesterification solution, the penicillin titer is 178560u / mL, add 48L purified water, then add 25.34kg penicillin G acylase, the enzyme activity is 155u / g; start stirring, add 3.0mol / L ammonia water to the feed solution, Control the pH of the feed solution to 8.10, control the reaction temperature to 31°C; react for 50 minutes, stop the reaction, separate the enzyme from the feed solution to obtain 285L of lysate, sample and determine the concentration of 6-APA to be 45.21g / L, and the cleavage yield to be 99.30 %;

[0038] (2) Extraction

[0039] The lysate obtained in step (1) was cooled down. When the temperature dropped to 6° C., 285 L of dichloromethane was added to the lysate. The temperature of the methylene chloride was 5° C. Under stirring conditions, 30% hydrochloric acid was adde...

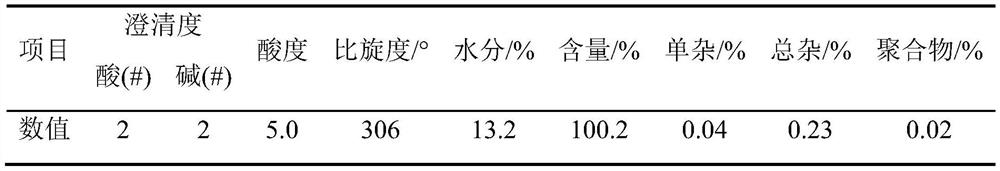

Embodiment 2

[0056] Embodiment 2 The method for preparing amoxicillin by deesterification solution according to the present invention

[0057] (1) Penicillin Potassium Cleavage

[0058] Take 200L of deesterification solution, the penicillin titer is 172980u / mL, add 40L of purified water, then add 24.55kg of penicillin G acylase, the enzyme activity is 155u / g, start stirring, add 3.0mol / L ammonia water into the reaction tank, Control the pH of the feed liquid to be 8.0-8.2, control the reaction temperature to be 28-31°C, react for 53 minutes, stop the reaction, separate the enzyme from the feed liquid to obtain 282L of lysate, take a sample to determine the concentration of 6-APA is 44.35g / L, crack The yield is 99.49%;

[0059] (2) Extraction

[0060] The lysate obtained in step (1) was cooled down. When the temperature dropped to 5° C., 141 L of dichloromethane was added to the lysate. The temperature of the methylene chloride was 5° C. Under stirring conditions, 30% hydrochloric acid wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Potency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com