Graphene/gallium arsenide solar cell preparation method

A solar cell and gallium arsenide technology, applied in the field of solar energy, can solve the problems of only 3.36% efficiency and unsatisfactory effect, and achieve the effects of facilitating industrial application, improving photoelectric conversion efficiency, and increasing fill factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

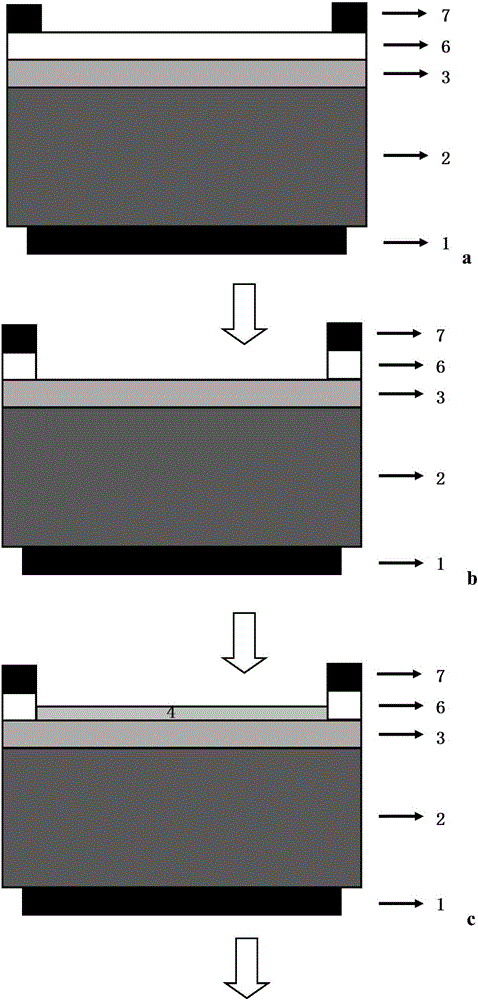

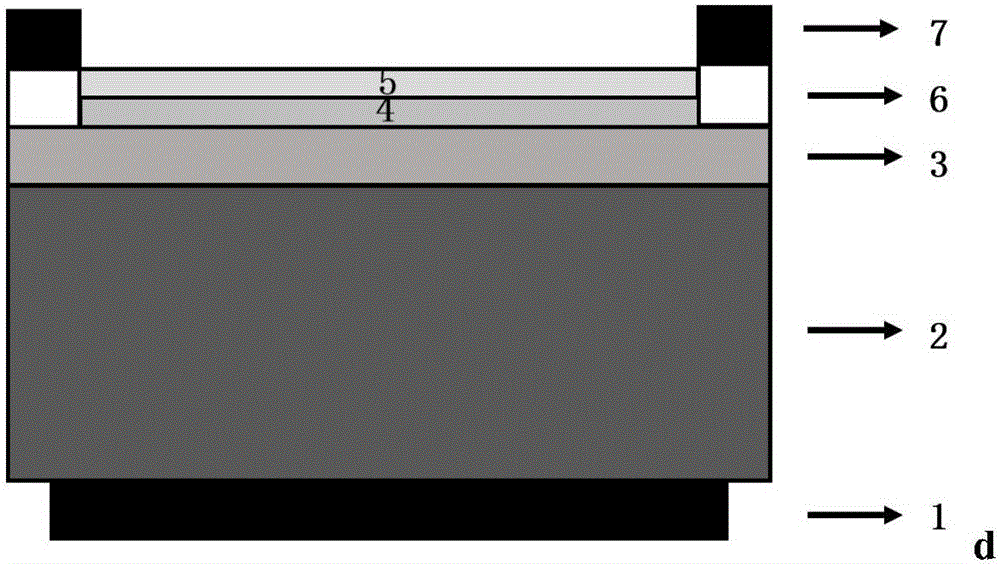

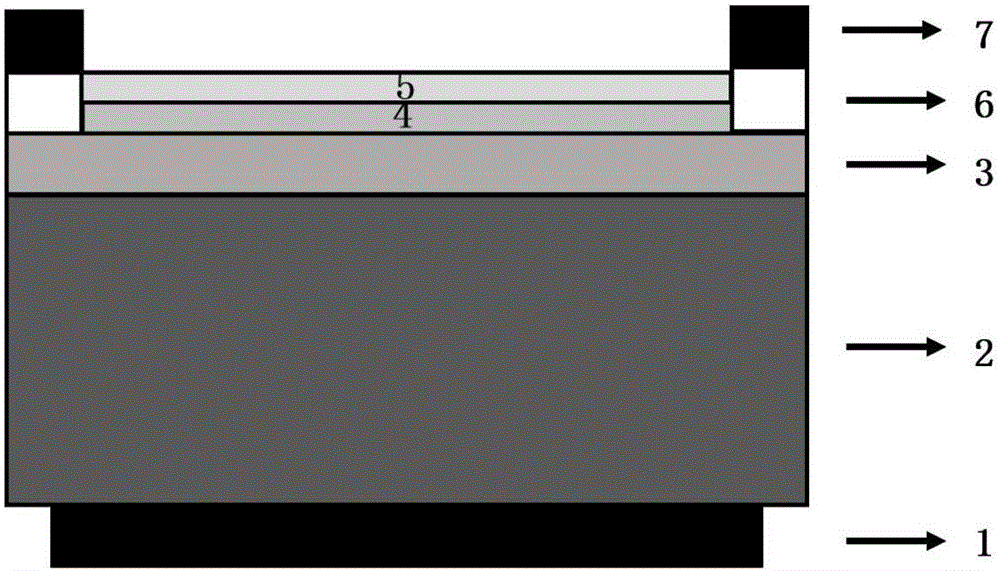

[0024] The invention provides a method for preparing a graphene / gallium arsenide solar cell, comprising the following steps:

[0025] 1) Prepare a window layer on the surface of the gallium arsenide epitaxial wafer, and then prepare a heavily doped gallium arsenide cap layer on the surface of the window layer;

[0026] 2) preparing a front electrode on the surface of the heavily doped gallium arsenide cap layer, and preparing a back electrode on the surface of the gallium arsenide epitaxial wafer away from the window layer;

[0027] 3) The heavily doped gallium arsenide cap layer between the front electrode grid lines is etched by a chemical etching method to expose the window layer;

[0028] 4) preparing a graphene layer on the surface of the exposed window layer;

[0029] 5) preparing an anti-reflection layer on the surface of the graphene layer to obtain the graphene / gallium arsenide solar cell.

[0030] In the present invention, gallium arsenide epitaxial wafers are firs...

Embodiment 1

[0082] 1) Epitaxial growth of 0.5 μm thick n-type GaAs buffer layer, 0.1 μm thick n-type AlGaAs back field, 3.2 μm thick n-type GaAs base layer, 0.5 μm thick p-type GaAs emitter layer on n-type GaAs substrate by MOCVD method, Then continue to epitaxially grow the p-type AlGaAs window layer with a thickness of 0.03 μm and the p-type heavily doped GaAs cap layer with a thickness of 0.5 μm;

[0083] 2) The n-type electrode of NiGeAu system is evaporated by electron beam on the lower surface as the back electrode, and the p-type electrode of TiPdAg system is evaporated by electron beam on the cap layer on the upper surface as the front electrode.

[0084] 3) Soak the epitaxial wafer in acetone at 60°C for half an hour, then rinse it with isopropanol, ethanol and deionized water; prepare a solution with a ratio of hydrochloric acid to water of 1:1, soak the epitaxial wafer for two minutes and then rinse it; Cover the hat layer pattern to be protected on the upper surface with photo...

Embodiment 2

[0095] 1) Epitaxial growth of 0.5 μm thick n-type GaAs buffer layer, 0.1 μm thick n-type AlGaAs back field, 3.2 μm thick n-type GaAs base layer, 0.5 μm thick p-type GaAs emitter layer on n-type Ge substrate by MOCVD method, Then continue to epitaxially grow the p-type AlGaAs window layer with a thickness of 0.03 μm and the p-type heavily doped GaAs cap layer with a thickness of 0.5 μm;

[0096] 2) The n-type electrode of NiGeAu system is evaporated by electron beam on the lower surface as the back electrode, and the p-type electrode of TiPdAg system is evaporated by electron beam on the cap layer on the upper surface as the front electrode.

[0097]3) Thin the epitaxial wafer substrate to the required thickness, soak it in acetone at 60°C for half an hour, then rinse it with isopropanol, ethanol and deionized water, and dry it with nitrogen; prepare piranha lotion and soak the epitaxial wafer Thirty seconds later, rinse it off and dry it with nitrogen; cover the cap layer to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com