Low pressure superheated steam assisted evaporation crystallization device and crystallization process

A technology of superheated steam and crystallization device, which is applied in the direction of evaporation, separation and crystallization, general layout of crystallization device, crystallization separation, etc. It can solve the problems of inconvenient collection of low-pressure steam, difficult practical operation, unsatisfactory effect, etc., and achieve maximum Utilize, realize energy, design ingenious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

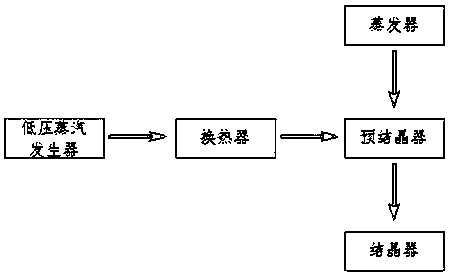

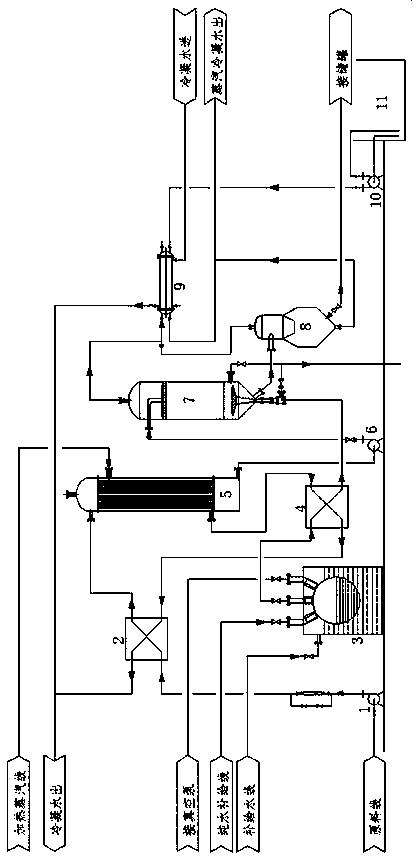

[0018] see Figure 1-Figure 4 , a low-pressure superheated steam assisted evaporation crystallization device, the crystallization device includes a material pump 1, a material preheater 2, a low-pressure steam generator 3, a heat exchanger 4, a falling film evaporator 5, a concentrated liquid delivery pump 6, a preheater Crystallizer 7, crystallizer 8 and condenser 9, the material preheater 2 is arranged between the material pump 1 and the falling film evaporator 5, connected by pipelines, the heat exchanger 4 is arranged in the low-pressure steam generator 3 Between the pre-crystallizer 7 and the pre-crystallizer 7, the pre-crystallizer 7 is connected to the condenser through a pipeline, and the dope delivery pump 6 is arranged between the falling film evaporator 5 and the pre-crystallizer 7, and the pre-crystallizer 7 is connected through a pipeline Connect crystallizer 8. In this technical solution, saturated steam under negative pressure condition is generated by a low-pr...

Embodiment 2

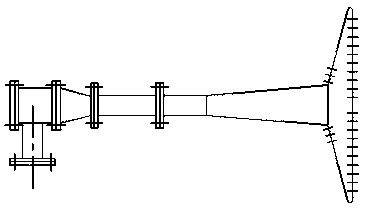

[0020] see figure 1 , figure 2 , as an improvement of the present invention, the pre-crystallizer 7 includes a crystallizer tank 13, a dope distributor 12 and a steam speed-up distributor 14, and the dope distributor 12 and the steam speed-up distributor 14 are set In the pre-crystallizer tank body, the steam speed-increasing distributor includes a steam distribution plate 17, a diffusion speed-increasing pipe 15 and a tee connection end, and the steam distribution plate is connected to the top of the diffusion speed-increasing pipe, and the diffuser The bottom of the speed-increasing pipe is connected with the three-way connecting step end. The thick liquid distributor 12 is larger than the opening of the ordinary material distributor, and the diameter of the opening is φ38. At the same time, the thick liquid distributor 12 is overlapped with the inner wall of the pre-crystallizer tank 13; the steam speed-increasing distributor It is composed of a three-way connection end ...

Embodiment 3

[0022] see figure 1 , figure 2 , as an improvement of the present invention, the crystallization device also includes a vacuum pump 10 and a pool 11, the vacuum pump is used to maintain the vacuum of the entire device, and one end of the condenser is connected through a pipeline. The vacuum degree of the system is mainly maintained by the vacuum pump 10, and the vacuum degree of the low-pressure superheated steam system is adjusted by an external vacuum pump system. In principle, the vacuum degree of the low-pressure superheated steam system is higher than that of the evaporation crystallization system. Other structures and advantages are exactly the same as those in the embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com