Method for manufacturing toothbrush marks, toothbrush with marks and marking mold

A marking and mold technology, which is applied to toothbrushes and marking molds to make toothbrush marks. It can solve the problems of unsightly and clear, complicated EDM production process, and long cycle, and achieve the effect of high-precision characters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

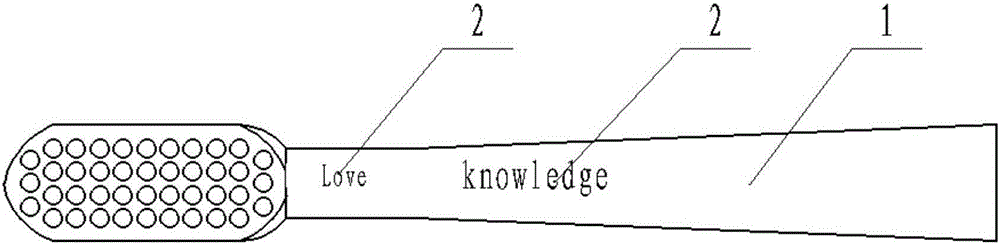

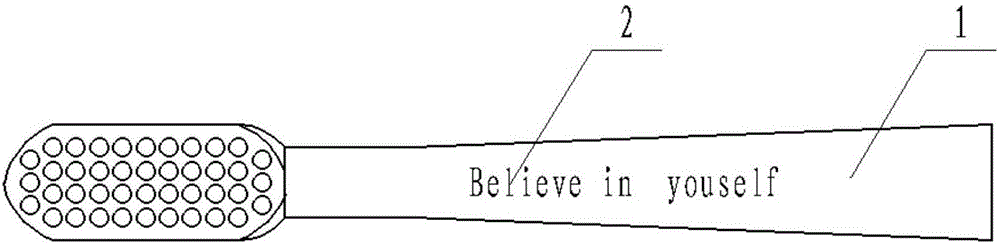

[0034] A method for making toothbrush marks, comprising making marks on the handle of the toothbrush body through mold imprinting, the marks are three-dimensional positive energy fonts or sentence shapes or protrusions composed of English letters, and the three-dimensional letters composed of English letters The positive energy font or sentence contains "a, b, c, d, e, f, g, h, i, j, k, l, m, n, o, p, q, r, s, t, u, v, w, x, y, z, A, B, C, D, E, F, G, H, I, J, K, L, M, N, O, P, Q, R, S, T, U, V, W, X, Y, Z".

[0035] Specifically, the mold mark is made on the mold by engraving machine or numerical control processing, and then the mold with the mold mark is used for the mark molding on the handle of the toothbrush body.

[0036] The positive energy font can have Love (love), Like (like), Light (brightness), smile (smile), sweet (sweetness), Learn (learning), longing (longing for), spring (spring), Confidence ( Confidence), Dreaming (dream), Fun (fun), Happiness (happiness), J...

Embodiment 2

[0039] On the basis of embodiment 1, the method for described mold imprinting comprises the following steps:

[0040] (1) Prepare the mould: use a laser engraving machine to scan and engrave the mark layer by layer in the mold cavity having the shape of the toothbrush body;

[0041] (2) Marking: the marked mold is placed in the injection molding machine, and the toothbrush body with the marked is formed by injection molding in the injection molding mold.

[0042] Laser engraving belongs to non-contact processing, no mechanical extrusion or mechanical stress, small heat-affected area, fine processing, no deformation of the workpiece, high processing efficiency, low cost, easy operation, and no pollution. Engraving marks in the mold cavity of the body shape can obtain sharp-edged and high-precision mold marks; because the mold marks are sharp-edged and high-precision, the toothbrush marks made by the mold mark are sharp-edged, high-precision, and three-dimensional Strong, can b...

Embodiment 3

[0044] On the basis of embodiment 2, preferably, wherein preparing mold comprises the steps:

[0045] a. Create the required font or sentence on the computer of the laser engraving machine or convert it through the CAD mold drawing;

[0046] b. Fix the metal mold on the three-dimensional workbench, adjust the Z-axis height, so that the metal mold processing surface reaches the focus position of laser engraving;

[0047] c. Find a corresponding graphic line, turn on the laser with the laser parameters of 9.5A current, adjust the X and Y axes of the three-dimensional workbench, so that the graphic on the metal mold coincides with the laser line, and use the coincidence line as a reference line, in the laser engraving machine computer Enter the font or sentence and the position size of the reference line as required, and fill the font or sentence with a line spacing of 0.001mm, and save the engraving content;

[0048] d. Adjust the laser control current to 14.5A, the effective v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com