Preparation method of double-transport channel sheet-like ceramic membrane with independent and regular distribution of two phases

A transport channel and ceramic membrane technology, which is applied to ceramic molding machines, chemical instruments and methods, and membranes, can solve the problems of complex preparation process, mutual blockage, and long channels of dual-phase ceramic membranes, so as to improve mass transfer efficiency, The effect of improving production efficiency and saving preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Because La 0.6 Sr 0.4 co 0.2 Fe 0.8 o 3 (LSCF) is more electronically conductive than SrCe 0.9 Y 0.1 o 3 (SCY) has good proton conductivity, so SCY is used as the continuous phase of the dual-phase membrane, and LSCF is used as the dispersed phase.

[0043] Add 10g of LSCF and 20g of SCY to an appropriate amount of polyethersulfone / NMP solution with a weight fraction of 20%, respectively, and fully mix them on a rapid mill to obtain two kinds of casting solutions, and then separate the two casting solutions Put it in a degasser and degas it with a vacuum pump for 1h.

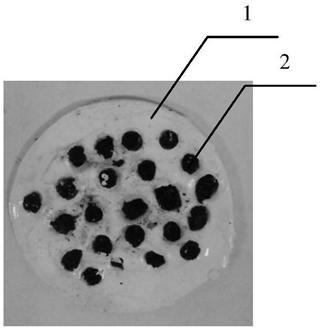

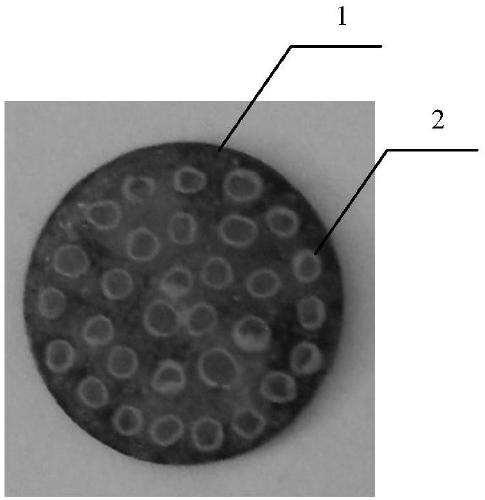

[0044] The LSCF casting solution was spun and cut into particles with a diameter of 0.4 mm and a length of 1.5 mm. The SCY casting solution is cast into a cylindrical mold with a diameter of 20mm and a thickness of 1.5mm, and at the same time, the sheared LSCF particles are evenly dispersed in SCY, and finally the mold is put into pure water for phase change solidification to obtain SCY / LSCF bip...

Embodiment 2

[0047] Combine 20g SCY and 10g NiFe 2 o 4 (NFO) were respectively added to an appropriate amount of polyethersulfone / NMP solution with a weight fraction of 20%, and were fully mixed on a rapid mill to obtain two kinds of casting solutions, and then the two casting solutions were put into degassing The device was degassed with a vacuum pump for 1 h.

[0048] The NFO casting liquid is spun on the spinning device and cut into particles with a diameter of 0.4mm and a length of 1.5mm. The SCY casting solution is cast into a cylindrical mold with a diameter of 20mm and a thickness of 1.5mm, and at the same time, the sheared NFO particles are evenly dispersed in SCY, and finally the mold is put into pure water for phase change solidification to obtain SCY / NFO dual-phase film precursor whose structure is as figure 2 . Only the continuous phase is SCY, and the dispersed phase is NFO.

[0049] The dual-phase film precursor was placed in an oven to dry, and then heated to 800°C in...

Embodiment 3

[0051] Add 20g of SCY and 10g of titanium oxide to an appropriate amount of polyethersulfone / NMP solution with a weight fraction of 20%, and mix them fully on a rapid mill to obtain two casting solutions, and then mix the two casting solutions Put them into a degasser and degas them with a vacuum pump for 1h.

[0052] The titania casting solution is spun on a spinning device and cut into particles with a diameter of 0.4 mm and a length of 1.5 mm. The SCY casting solution is cast into a cylindrical mold with a diameter of 20mm and a thickness of 1.5mm. At the same time, the sheared titanium dioxide particles are evenly dispersed into the SCY, and finally the mold is put into pure water for phase change solidification. Obtain SCY / titania dual-phase film precursor, its structure is as follows figure 2 . Only the continuous phase is SCY, and the dispersed phase is titanium oxide.

[0053] The dual-phase film precursor was placed in an oven to dry, and then heated to 800°C in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com