A process and device for acetylene concentration

An acetylene and process technology, applied in the field of acetylene preparation, can solve problems such as incomplete separation of advanced alkynes, and achieve the effects of reducing the content of advanced alkynes, reducing usage, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

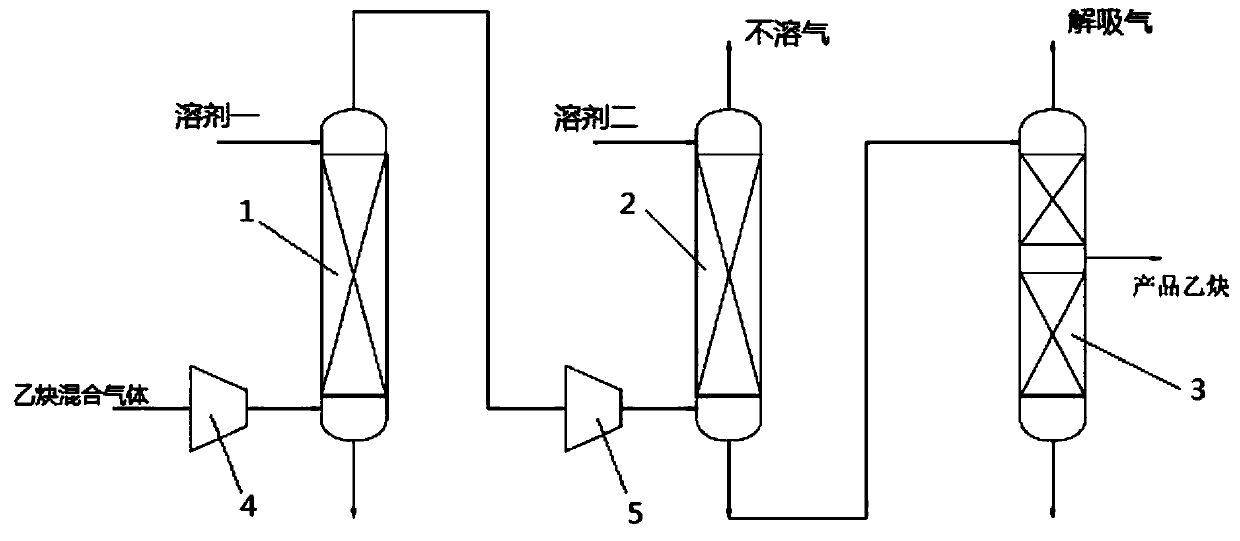

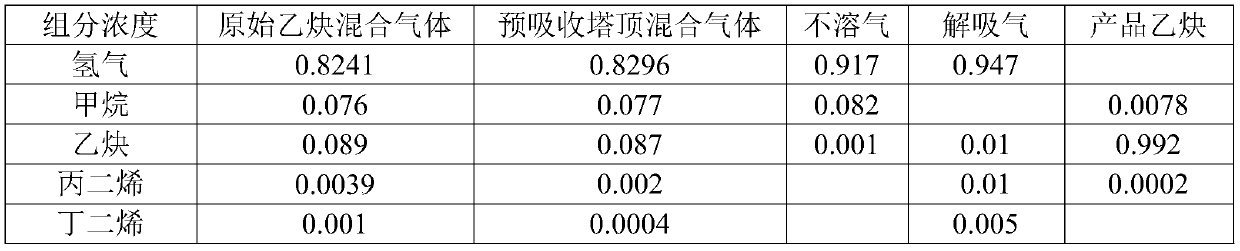

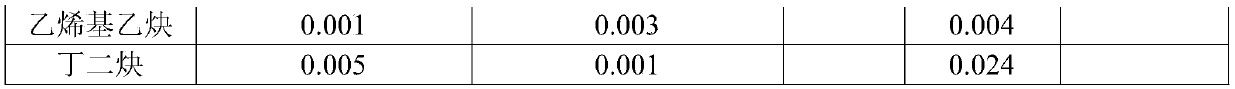

[0026] Such as figure 1 As shown, the mixed gas containing acetylene is compressed by the compressor I and then boosted from normal pressure to 0.15MPa (absolute), then enters the bottom of the pre-absorption tower, and is in countercurrent contact with the pre-absorption solvent diesel oil from the top, and the higher acetylene in the dilute acetylene Hydrocarbons (propadiene, diacetylene, etc.) are absorbed, and the pre-absorption tower is a packed tower. After the mixed gas is pre-absorbed, it comes out from the top of the pre-absorption tower, and then goes through compressor II for a second pressurization. After the pressure is increased to 0.7MPa (absolute), it enters the bottom of the main absorption tower, and the main absorption solvent dimethylformamide from the top. The acetylene and a small amount of higher alkynes in the gas are absorbed by the main solvent, and the insoluble gases such as hydrogen, methane, and carbon monoxide are discharged from the top of the m...

Embodiment 2

[0032] Such as figure 1 As shown, the mixed gas containing acetylene is compressed by the compressor I and then boosted from normal pressure to 0.35MPa (absolute), then enters the bottom of the pre-absorption tower, contacts with the pre-absorption solvent decene from the top in countercurrent contact, and the high-grade in the dilute acetylene Alkynes (propadiene, diacetylene, etc.) are absorbed, and the pre-absorption tower is a tray tower. After the mixed gas is pre-absorbed, it comes out from the top of the pre-absorption tower, and then goes through the compressor II for a second pressurization. After the pressure is increased to 1.5MPa (absolute), it enters the bottom of the main absorption tower, and the main absorption solvent N- from the top. Methylpyrrolidone is in countercurrent contact, acetylene and a small amount of higher alkyne in the gas are absorbed by the main solvent, and insoluble gases such as hydrogen, methane, and carbon monoxide are discharged from the...

Embodiment 3

[0037] Such as figure 1 As shown, the mixed gas containing acetylene is compressed by the compressor I and then boosted from normal pressure to 0.5MPa (absolute), then enters the bottom of the pre-absorption tower, and contacts with the pre-absorption solvent diethylene glycol dibutyl ether from the top in countercurrent, Higher alkynes (propadiene, diacetylene, etc.) in dilute acetylene are absorbed, and the pre-absorption tower is a plate tower. After the mixed gas is pre-absorbed, it comes out of the top of the pre-absorption tower, and then goes through the compressor II for a second pressure increase. After the pressure is increased to 2.5MPa (absolute), it enters the bottom of the main absorption tower, and is mixed with the main absorption solvent liquid ammonia from the top. Countercurrent contact, acetylene and a small amount of higher alkynes in the gas are absorbed by the main solvent, and insoluble gases such as hydrogen, methane, and carbon monoxide are discharged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com