Curing agent for epoxy anticorrosion primer and preparation method thereof

An anti-corrosion primer and curing agent technology, which is applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve problems such as difficulty in dispersion, poor stability, and easy agglomeration and settlement of graphene, so as to reduce film thickness and film density , good stability, excellent anti-settling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

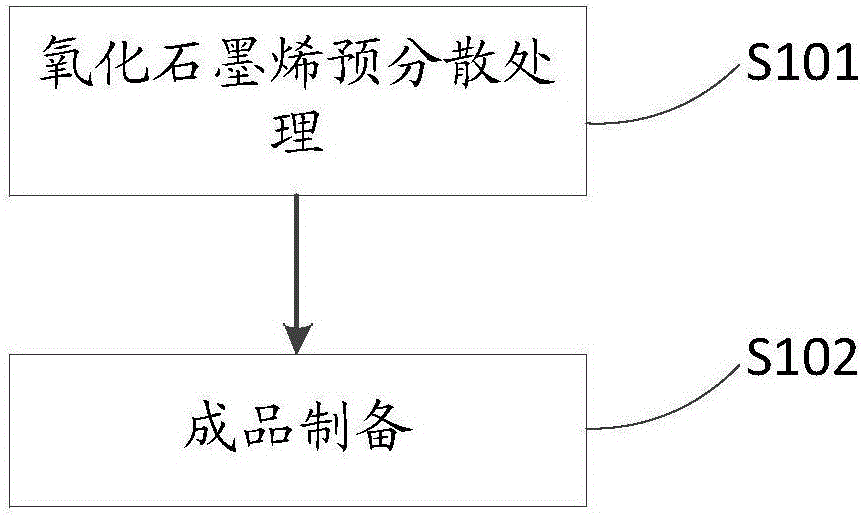

[0027] Such as figure 1 Shown, the preparation method of curing agent for epoxy anticorrosion primer in the present invention comprises:

[0028] S101. Graphene oxide pre-dispersion treatment: uniformly disperse the formulated amount of graphene oxide in the formulated amount of mixed diluent to obtain a graphene oxide dilution;

[0029] S102. Finished product preparation: add the dicyclohexyl dicarboimide of the formula and the polyamide resin half of the formula into the diluent of graphene oxide, heat up to 100°C-110°C, turn on condensing reflux, and react under stirring conditions 2 to 4 hours; then lower the temperature to 45° C. to 55° C., add the remaining polyamide resin, mix evenly, and filter to remove impurities to obtain the curing agent for epoxy anticorrosion primer.

[0030] Preferably, in the step S101. In the graphene oxide pre-dispersion treatment, the graphene oxide is uniformly dispersed in the mixed diluent by ultrasonic dispersion, the ultrasonic dispers...

Embodiment 1

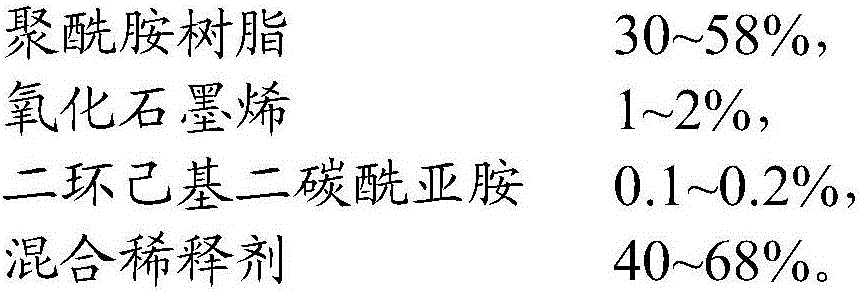

[0036] 1) The dosage of each component is as follows:

[0037]

[0038]

[0039] 2) Refer to attached figure 1 Middle process, preparation of curing agent for epoxy anti-corrosion primer

[0040] S101. Graphene oxide pre-dispersion treatment: uniformly disperse the formulated amount of graphene oxide in the formulated amount of mixed diluent by ultrasonic dispersion to obtain a graphene oxide diluent; the ultrasonic dispersion condition is 300W, and the ultrasonic time is 1h;

[0041] S102. Finished product preparation: add the dicyclohexyl dicarboimide and half the polyamide resin into the graphene oxide diluent, heat up to 100°C, turn on condensing reflux, and react under 300r / min stirring condition 4h; then lower the temperature to 45°C, add the remaining polyamide resin, stir evenly, filter and discharge the material to obtain the curing agent for epoxy anticorrosion primer.

Embodiment 2

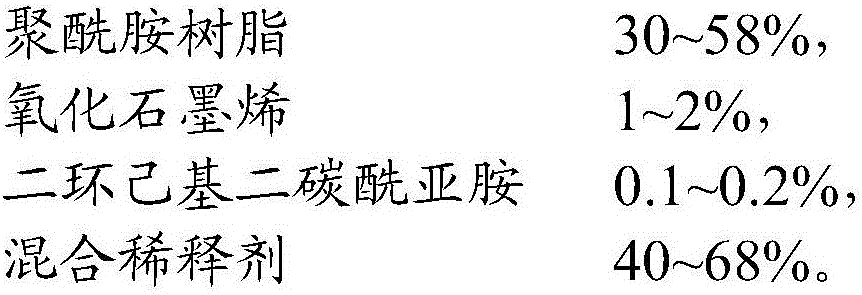

[0043] 1) The dosage of each component is as follows:

[0044]

[0045] 2) Refer to attached figure 1 Middle process, preparation of curing agent for epoxy anti-corrosion primer

[0046] S101. Graphene oxide pre-dispersion treatment: uniformly disperse the formulated amount of graphene oxide in the formulated amount of mixed diluent through ultrasonic dispersion to obtain a graphene oxide diluent; the ultrasonic dispersion condition is 400W, and the ultrasonic time is 0.5h;

[0047] S102. Finished product preparation: Add the dicyclohexyl dicarboimide and half the polyamide resin into the graphene oxide diluent, heat up to 110°C, turn on condensing reflux, and react under 400r / min stirring condition 3h; then lower the temperature to 50°C, add the remaining polyamide resin, stir evenly, and filter through a 120-mesh filter to remove impurities to obtain the curing agent for epoxy anti-corrosion primer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| amine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com