Visible light curing type frame seal adhesive composition

A composition and visible light technology, applied in the direction of adhesive additives, modified epoxy resin adhesives, non-polymer adhesive additives, etc., can solve the cost increase of photomask, non-clean light source of ultraviolet light source, liquid crystal destruction, etc. problem, to achieve the effect of saving mask cost, high initiation efficiency, and saving alignment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

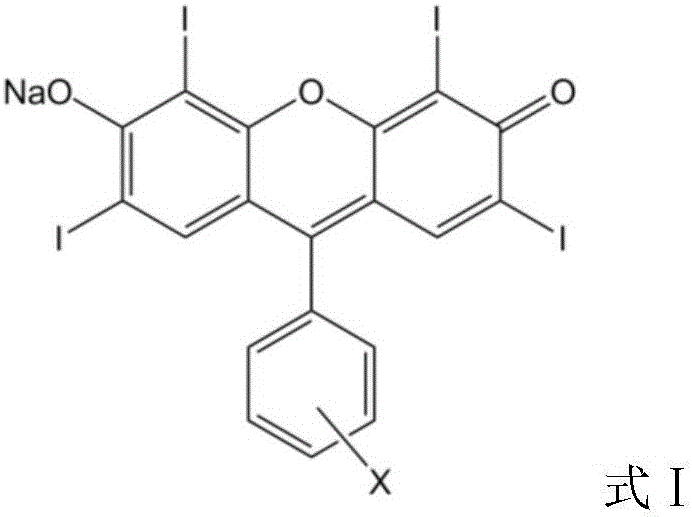

[0038] A visible light-curable frame sealant composition, comprising the following components in parts by weight, 5 parts of epoxy acrylic resin, 5 parts of polymethyl methacrylate, 1 part of photoinitiator system, 1 part of 3,5-dimethacrylate Methylaniline, 5 parts of silicon dioxide powder, 0.2 part of p-hydroxyanisole, in the present embodiment photoinitiator is:

[0039]

Embodiment 2

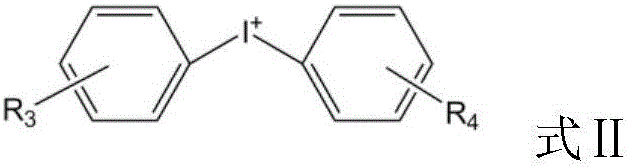

[0041] A visible light curing type sealant composition, including the following components in parts by weight, 35 parts of epoxy acrylic resin, 35 parts of polymethyl methacrylate, 5 parts of photoinitiator system, 5 parts of 3,5-di Methylaniline, 20 parts of silicon dioxide powder, 3 parts of p-hydroxyanisole, the photoinitiating system in the present embodiment is:

[0042] combination, the molar ratio between the two is 1:1.

Embodiment 3

[0044] A visible light curing type sealant composition, including the following components in parts by weight, 20 parts of epoxy acrylic resin, 15 parts of polymethyl methacrylate, 3 parts of photoinitiator system, 2 parts of 3,5-di Methylaniline, 12 parts of silicon dioxide powder, 2 parts of p-hydroxyanisole, in the present embodiment photoinitiator is:

[0045] combination, the molar ratio between the two is 1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com