Uniform-appearance and high-color-purity Mn4+ activated red fluoride luminescent material prepared by using micro-emulsion method

A technology with red luminescence and high color, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., and can solve problems such as insufficient preparation methods of fluoride red phosphors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] First add 0.20 g of dodecylbenzenesulfonic acid to 10 ml of hydrofluoric acid solution containing 0.12 g of sodium hexafluoromanganate and stir for 10 to 30 minutes, then dissolve 0.20 g of silicon dioxide in 5 ml of hydrofluoric acid solution and added to the above solution to continue stirring for 10 to 30 minutes. Finally, add 0.50 g of sodium fluoride and continue stirring for 60 to 120 minutes. The resulting precipitate was washed with anhydrous methanol, and dried in a vacuum oven for 24 hours to obtain the desired Na 2 SiF 6 :Mn 4+ product.

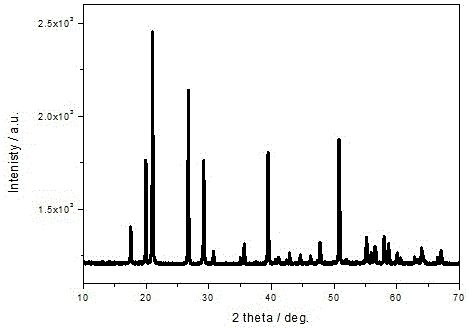

[0015] The XRD diffraction pattern of this fluorescent powder is attached figure 1 shown, with the standard card JCPDS 33-1280 (Na 2 SiF 6 ) in contrast, the two are completely consistent, and no diffraction peaks of any heterogeneous phases are observed, which indicates that the samples we synthesized have a single crystal phase.

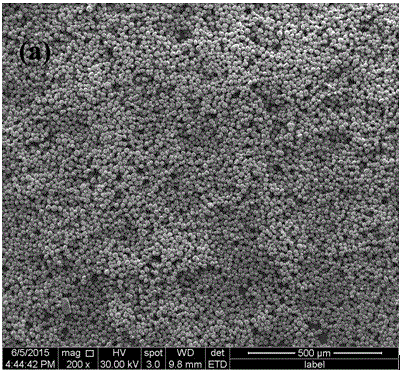

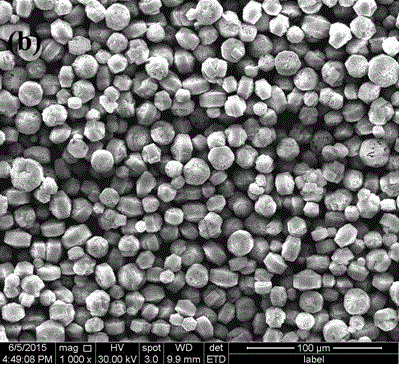

[0016] Accompanying drawing 2 shows the scanning electron microscope picture of sample...

Embodiment 2

[0020] First add 0.20 g of dodecylbenzenesulfonic acid to 10 ml of hydrofluoric acid solution containing 0.12 g of sodium hexafluoromanganate and stir for 10 to 30 minutes, then dissolve 0.40 g of titanium dioxide in 5 ml of hydrofluoric acid solution and Add to the above solution and continue to stir for 10-30 minutes. Finally, add 0.50 g of sodium fluoride and continue stirring for 60 to 120 minutes. The resulting precipitate was washed with anhydrous methanol, and dried in a vacuum oven for 24 hours to obtain the desired Na 2 TiF 6 :Mn 4+ product.

Embodiment 3

[0022] First add 0.20 g of dodecylbenzenesulfonic acid to 10 ml of hydrofluoric acid solution containing 0.12 g of sodium hexafluoromanganate and stir for 10 to 30 minutes, then dissolve 0.53 g of germanium dioxide in 5 ml of hydrofluoric acid solution and added to the above solution to continue stirring for 10 to 30 minutes. Finally, add 0.50 g of sodium fluoride and continue stirring for 60 to 120 minutes. The resulting precipitate was washed with anhydrous methanol, and dried in a vacuum oven for 24 hours to obtain the desired Na 2 GeF 6 :Mn 4+ product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com