Oligomer flocculating microalgae utilization method and application method thereof

A technology of oligomers and microalgae, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve problems such as refractory degradation, easy pollution, and influence of medium recycling, and achieve high separation efficiency, The effect of eliminating surface repulsion and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1: Flocculation separation of Scenedesmus sp

[0037] (1) Preparation of oligomers

[0038] Step 1: Take 5mL of distilled water in a 50mL beaker, slowly add 15mL of concentrated sulfuric acid (analytical grade), let stand and cool to room temperature, and set aside.

[0039] Step 2: Take 291mL of absolute ethanol in a 500mL clean beaker, then add 9mL of triaminotrimethoxysilane, and stir for 1min.

[0040]Step 3: Put 1 mL of the solution in Step 1 into the solution in Step 2, stir for 1 min, let stand for 21.5 h, centrifuge, rinse with absolute ethanol three times, and then dry in a vacuum oven at 80°C for 12 h to obtain the oligomer mixture. Characterize it, the results are as follows:

[0041] 29 SiNMR (119MHz,D 2 O): δ-68.67, -58.94, -48.97;

[0042] 1 HNMR (300MHz,D 2 O,25℃):δ3.54(q,nH),δ2.91(t,6nH),δ1.69(d,6nH),δ1.07(t,1.5nH),δ0.62(t,6nH );

[0043] 13 CNMR (75MH Z, D. 2 O, 25°C): δ57.42, 41.71, 20.62, 16.79, 8.67;

[0044] FTIR (KBr, cm -1 ):...

Embodiment 2

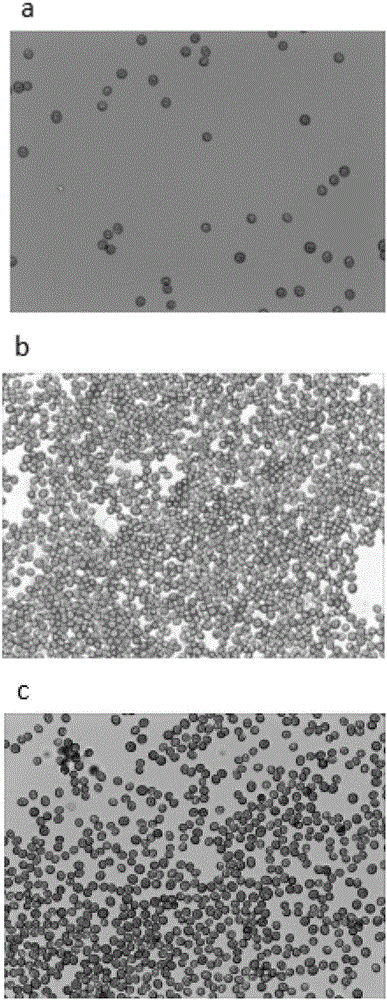

[0052] Example 2: Observation of cell activity

[0053] Cell viability before and after flocculation of Scenedesmus sp in Example 1 was determined using Evans blue solution staining (see figure 1 ). The specific operation is as follows: take 1 mL of the microalgae liquid after flocculation of the microalgae in Example 1, remove the supernatant after centrifugation, then add 100 μL of 1 wt% Evans blue solution to the centrifuged microalgae, and incubate at room temperature for 3 hours. Then wash twice with distilled water to remove excess and released dye. Then the washed microalgae were observed and photographed with an optical microscope. Since the Evans blue solution diffuses into the protoplasm of the destroyed microalgae and stains it with color, the destroyed and dissolved microalgae will change from green to blue, while the intact cells remain the same green.

[0054] in figure 1 Middle: Microalgal cells before flocculation (a); Microalgal cells after heating at 121...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com