Method for preparing H13 steel by electroslag remelting of electric conducting crystallizer

A technology of electroslag remelting and crystallizer, which is applied in the field of electroslag remelting and smelting, can solve problems such as difficult to obtain surface quality and internal quality, achieve good surface quality and internal quality, reduce the content of impurity elements, and avoid poor surface quality. poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

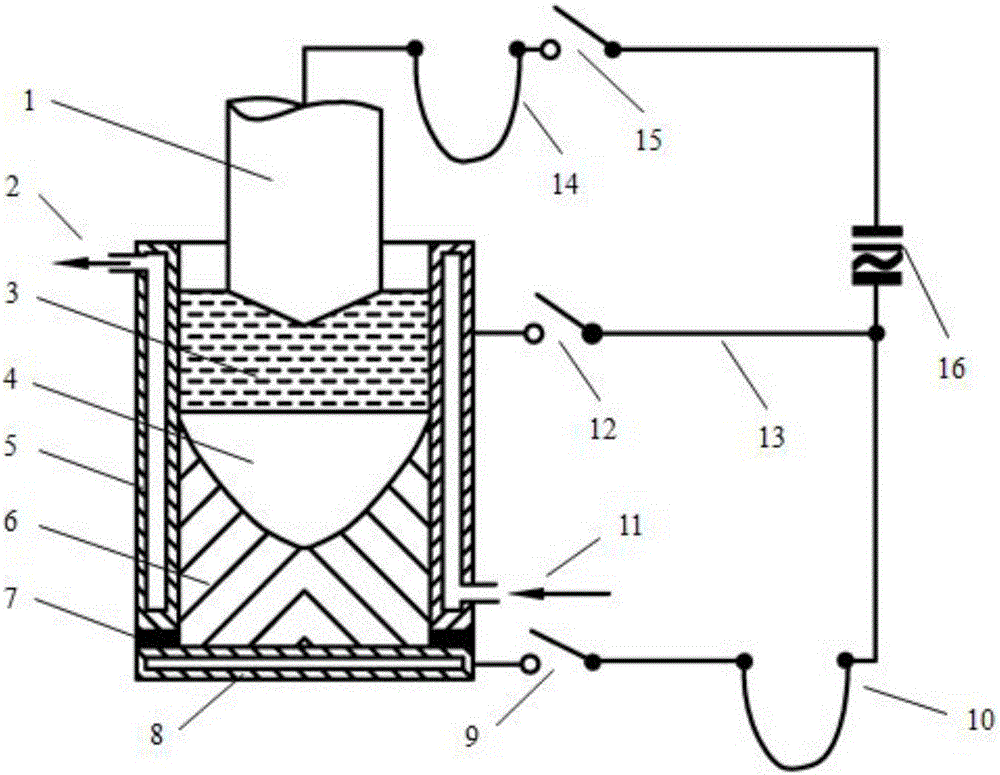

[0054] A method for preparing H13 steel by electroslag remelting of a conductive mold. The diameter of the conductive mold is 350 mm. The schematic diagram of the electroslag remelting of the conductive mold is as follows figure 1 As shown, it specifically includes the following steps:

[0055] Step 1, preparing slag:

[0056] Fluorite, lime, alumina and fused magnesia are used as raw materials to prepare slag, so that the mass percentage of slag is: CaF 2 : 55%, CaO: 20%, Al 2 o 3 : 22%, MgO: 3%, the quality of slag is 24kg;

[0057] Step 2, baking slag:

[0058] Use a box-type resistance furnace to heat the slag at 600°C for 6 hours, and take it out as needed;

[0059] Step 3, prepare ingredients:

[0060] (1) Place the arc ignition ring made of the same material as H13 steel in the bottom water tank of the electroslag furnace, and place the arc ignition agent on the arc ignition ring; among them, the arc ignition agent is CaF 2 and TiO 2 Arc cuttings prepared from a...

Embodiment 2

[0077] A kind of conductive crystallizer electroslag remelting prepares H13 steel, and the diameter of its conductive crystallizer is 280mm, specifically comprises the following steps:

[0078] Step 1, preparing slag:

[0079] Fluorite, lime, alumina and fused magnesia are used as raw materials to prepare slag, so that the mass percentage of slag is: CaF 2 : 52%, CaO: 21%, Al 2 o 3 : 23%, MgO: 4%, the quality of slag is 16kg;

[0080] Step 2, baking slag:

[0081] Use a box-type resistance furnace to heat the slag at 700 ° C for 5 hours, and take it out as needed;

[0082] Step 3, prepare ingredients:

[0083] (1) Place the arc ignition ring made of the same material as H13 steel in the bottom water tank of the electroslag furnace, and place the arc ignition agent on the arc ignition ring; among them, the arc ignition agent is CaF 2 and TiO 2 Arc cuttings prepared from a mixture, by mass ratio, CaF 2 :TiO 2 =(40~60):(40~60);

[0084] (2) Evenly add the baked slag int...

Embodiment 3

[0100] A kind of conductive crystallizer electroslag remelting prepares H13 steel, and the diameter of its conductive crystallizer is 600mm, specifically comprises the following steps:

[0101] Step 1, preparing slag:

[0102] Fluorite, lime, alumina and fused magnesia are used as raw materials to prepare slag, so that the mass percentage of slag is: CaF 2 : 54%, CaO: 24%, Al 2 o 3 : 20%, MgO: 2%, the quality of slag is 72kg;

[0103] Step 2, baking slag:

[0104] Use a box-type resistance furnace to heat the slag at 800 ° C for 5 hours, and take it out as needed;

[0105] Step 3, prepare ingredients:

[0106] (1) Place the arc ignition ring made of the same material as H13 steel in the bottom water tank of the electroslag furnace, and place the arc ignition agent on the arc ignition ring; among them, the arc ignition agent is CaF 2 and TiO 2 Arc cuttings prepared from a mixture, by mass ratio, CaF 2 :TiO 2=(40~60):(40~60);

[0107] (2) Evenly add the baked slag into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com