Method for testing protein in tobacco and tobacco products through automatic azotometer

A nitrogen analyzer and protein technology, applied in nitrogen determination, chemical method analysis, instruments, etc., can solve the problems of long detection cycle, high labor intensity, safety risks for human body and environment, etc., to achieve high accuracy and reduce work. Labor intensity, the effect of reducing safety risks and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

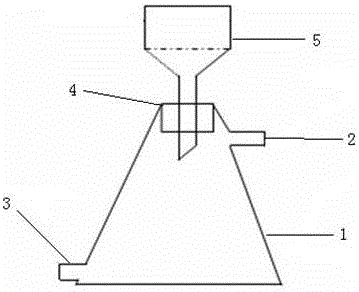

Method used

Image

Examples

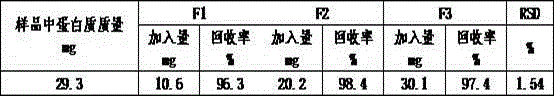

Embodiment 1

[0019] ① Accurately weigh 0.5000g of the flue-cured tobacco sample that passed through the 0.45mm sieve into a 300mL conical flask, weigh 15 parts in total, sample number 1-15, add 10.0mg casein standard sample to No. Add 20.0 mg casein standard sample to No. 10, 11, and 12, add 30.0 mg casein standard sample to No. 13, 14, and 15, and do 3 blank tests at the same time;

[0020] ② Add 75mL of 0.5% acetic acid solution to each Erlenmeyer flask, heat and keep boiling for 15min;

[0021] ③Quickly use quantitative filter paper with a diameter of 150mm to perform suction filtration in a vacuum filtration device, and rinse the Erlenmeyer flask and the precipitate with 0.5% acetic acid solution until the filtrate is colorless, then transfer the filter paper and the precipitate to a digestion tube with a volume of 250mL;

[0022] ④Add 1.5g K to the digestive tube 2 SO 4 and 0.15g CuSO 4 • 5H 2 0, then add 15mL of concentrated sulfuric acid;

[0023] ⑤ Place the digestive tube on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com